- Why do I need a floor heater?

- Advantages and disadvantages of expanded clay

- Methods expanded clay floor warming

- Warming top of compacted soil in private homes and structures on the ground

- Warming of the wooden or concrete floors in apartments

- How to choose the layer thickness and material fraction

- Step by step description of warming the floor technology

Most professionals and builders chosen for the repair of cement-concrete screed floor. An excellent alternative for warming a floor is keramzit. Use of such a material is possible as in apartment houses, and in the private sector, and easy installation, low cost of the floor of the expanded clay pleasantly surprise consumers.

Why do I need a floor heater?

As known, Air is the most effective substance, which has insulating properties. Concerning, all materials, which insulated various surfaces, are porous - air is delayed even in the smallest pores and thus prevents the loss of heat. The material for the insulation must always have a small density, to cope well with the assigned task.

The main function is to provide a floor insulation comfortable living room. Besides, good thermal insulation and sound insulation should be carried out to protect the structure from the formation of mold and mildew. Expanded clay copes with all enumerated tasks.

Produce such material from clay legkoplavnoy, which is placed in a thermal chamber and to soften the dough consistency. After supplying a high-temperature, clay boils, and there are pores. After solidification produces small fraction, and these are called expanded clay.

This type of material is a bulk and because of its natural qualities of a longer life, than other types of insulation for floors.

Advantages and disadvantages of expanded clay

This insulation material has its advantages, among which are the:

- Environmental Safety. Expanded clay - natural material, and therefore does not pose a risk to human. Even at high temperatures, or reacting with other substances, this material does not contain harmful emissions.

- The presence of heat and sound insulation properties. The porosity of the material significantly increases its thermal conductivity, as well as insulation against noise.

- Low weight. The presence of numerous fine pores make the material easy;

- Fire safety. Expanded clay has properties of a fire.

- Long life. Thanks to, that the material is natural, its service life reaches 10 years old.

- Easy installation. Insulate the floor can be independently expanded clay, it does not require specific skills.

- surface leveling. Expanded clay will create an even layer for subsequent processing of the floor surface.

- The strength of the material allows to use it even in industrial premises, because it is wear-resistant.

- Availability price category. Compared with other types of heaters, expanded clay is relatively inexpensive cost.

With so many advantages, keramzite floor insulation also is not without downsides:

- Compared with polystyrene and mineral wool, expanded clay loses in thermal conductivity.

- When installing the insulation may cause a certain amount of dust due to the properties of clay.

- LECA is a moisture sorbing material, when struck by water, it is very difficult to dry.

Proper stacking technology will help avoid some of the shortcomings of this material.

There is also a new technique semi-dry screeds which helps to make the floor alignment in one day in an apartment.

Methods expanded clay floor warming

Before you insulate the floor expanded clay, necessary to carry out the preparatory work on the surface. There are several ways to provide thermal insulation through the material:

Warming top of compacted soil in private homes and structures on the ground

Such a warming of the floor is used for private or suburban homes, as well as garages and baths. This option is also divided into a number of ways:

- Floor on joists on the ground. To begin with removed floor covering, then dismantled logs. Further lay waterproofing material, and only then use the bulk concrete block. The next layer is poured small fraction material, e.g. river sand. At the end of, laid reinforced mesh and fill screed.

- Paul lag, mounted on brick poster. In this case, the concrete block is filled to a level paved brick supports. Usually, this method is used for thermal insulation of the wooden floor, so the poles nailed boards, and then wooden planks. After they use other types of insulation and poured concrete floor.

- Concrete and expanded clay insulation. Such a method is used in garages and baths. Directly on the ground is laid waterproofing, and then make a screed, which includes cement, sand and expanded clay. This solution was poured on the floor surface and are drying. Used to strengthen the special cement milk.

Warming of the wooden or concrete floors in apartments

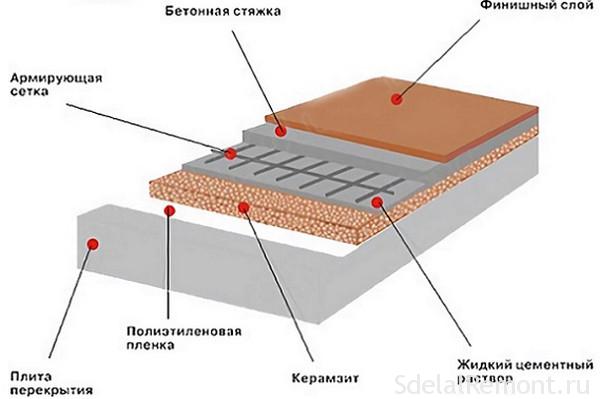

In order to insulate the floor in a multistory apartment house, you must have an adequate supply of ceiling heights, as the technology to comply with the need to raise the level of the floor. The entire process consists of the removal of the floor covering, remove all cracks and crevices on the floor surface. Next, you need to apply waterproofing, that is most appropriate in this room, then pour a layer of expanded clay. Its height should be equal to 5-10 cm. At the end of, lay a reinforced mesh and fill screed.

When choosing a method of expanded clay insulation guided by the operating floor conditions and the type of substrate.

How to choose the layer thickness and material fraction

To keramzit floor insulation effect brought necessary to calculate the layer thickness, and select the correct size fraction. Typically used insulation layer wooden floors in 40 cm, for concrete base 30 cm. If the warming takes place in a private home for the floor slab, there will be enough layer 20 cm.

Correct calculation of the layer thickness depends on the expected load on the next floor - it is higher than, the higher layer should be. In order to get the total amount of material required is necessary to multiply the area of the premises on the expanded clay consumption in the 1 quarter. m. - it's approximately 10 liters for layer 1 cm.

Also important is the choice of expanded clay fraction. To date, manufacturers have expanded clay in three fractions: small - up 5 mm, average - up 20 mm, and large - up 40 mm. The first option is used most often for alignment subfloor, as well as additives in concrete screed. Average granules are used for thermal insulation in apartments, and large to insulate the floor in the garage.

Step by step description of warming the floor technology

Expanded clay floor warming can be performed independently, should just stick to the rules and comply with certain technology work.

- Training. The first step consists in the dismantling of the old flooring, as well as his thorough cleaning. Everything, which was to lay on the floor before, must be removed, and then to clear the base. More often, at the base of the floor is concrete slab. For use hard surface cleaning metal brushes, that will even remove stale garbage and dirt. Once cleaned floor, Sweep or vacuum clean it, and then wash with water. All detected cracks and holes must be sealed with a solution or with special glue. Cracks in the floor sealed with foam.

- protection of communications. For, so as not to damage the wiring and other communications, they must be secured. This is done by means of special fasteners, pre-wound tubes and wires polyethylene.

- The next important stage - floor waterproofing. It is best to use the type of coating insulation - a special bitumen mastic. It is applied to the prepared surface with a wide brush or roller with a long handle. It must be remembered, that the waterproofing is also applied around the perimeter of the walls to a height of about 10 cm from the floor. Bituminous waterproofing must dry, hereafter is better to repeat more layers.

- floor screed. Before you perform screed must install beacons. For use in expanded clay screed beacons Tshape, made of metal. Installation of beacons is also produced as well as for conventional cement screeds.

Further there is a floor screed. She may be dry or filler. If the first option is selected, you just need to fill expanded clay to the desired thickness. After that, the floor itself is directly mounted.

Liquid screed is carried out in a number of approaches: first expanded clay mixed with a solution for floor and pour layer. The second stage is filled with normal concrete screed, which is aligned with the beacons. complete drying of the floor time is about a month.

Thermal insulation of the floor is an effective method haydite insulation not only in homes, but also in other areas, not intended for permanent residence.