- cement

- clay

- lime

- combined.

- Preparing grout

- Tips for preparation of other types of solutions for walls

- Step by step instructions for creating a mixture of lime-based

- Clay wall covering

- The dry plaster mixture

- How to prepare a base for plastering?

- Plaster walls with cement mortar beacons

- Calculate the amount of material for plaster help calculator

- Dry mixes for plaster and versatile formulations

- Universal mixture

on, how well made mixture for plaster walls - it depends on the quality and timing of the entire operation finishes. What types of products and how to correctly make the solution will learn in this article! Overview of compositions and solutions which the plaster walls.

cement

Among the most common can be identified cement. Suitable for moderate climate, thoroughly grasped for 12 hours, characterized by high strength and affordability.

clay

It is used for finishing wood surfaces, relatively solid binder. It has air permeability and has a high thermal insulation capacity.

lime

Most often performed in tandem with plaster, for improving the strength and reliability of the composition. For solutions used slaked lime. Building plaster accelerates the setting and hardening increases the level of finishing. It does not shrink and can be used in pure form.

combined.

This solution uses various composite components (Cement, lime, gypsum and TD).

special plaster.

The mixture was introduced into the corresponding correction, for forming various kinds of coating otelochnogo (decorative veneer).

Proportions solution wall plastering

Preparing grout

Cement mixtures for plaster walls can be divided into 2 species:

- with the addition of sand to the main ingredient - for surfacing (the adhesion of such impurities from the plaster bad);

- with lime admixture.

In each of these compositions may add special polymer additives and inorganic fillers. Thanks to them, the mixture becomes more plastic and frost.

Cement mortar for plastering the walls with his own hands is prepared as follows:

- Take 1 part cement.

- 3 parts sand.

- The water in the required amount, so the mixture was creamy state.

- Liquid soap to the soap solution.

Mix all the ingredients in the right proportions, removed all the lumps and bumps, the mixture is ground several times. It should be a uniform color.

ATTENTION! In order to translate the "product", better to make the solution in small amounts. After all, in minutes 40 the mixture begins to lose its basic properties, which will lead to poor-quality surface finish.

Composition for plaster walls of the solution may be too bold, when it sticks to the trowel. When dry it will give a strong shrinkage, and the surface will crack over time.

Plaster walls grout normal consistency leaves a thin layer of building material solution, that allows you to carefully handle all the bumps and achieve quality results.

"Skinny" the composition of the plaster for the walls need to adjust, add more cement and stir well.

RECOMMENDATION! A solution for plaster with a limited amount of sand is obtained plastic minee, Therefore, the correct ratio - 1:3.

Tips for preparation of other types of solutions for walls

- The solution is to plaster walls on the basis of lime is so: 1 the lime and 2-3 parts sand, depending on the desired consistency. It used the mixture immediately after preparation.

- Clay mixture for plaster retain their quality for a long time, to obtain the desired solution is necessary in advance soaked clay mixed with sand, add the right amount of water and mix until a creamy consistency. Such a solution is good coat outer portions of the coal stoves and pipes.

- For the preparation of the lime-gypsum mortar for plaster walls must first be poured into the water tank, then pour plaster and mix thoroughly. All work must be done quickly, and kneading the mixture at once a large number of. Composition: one part cement, 1\2 part of hydrated lime, 5 parts of sand and 300 ml liquid soap.

- Preparation of cement mortar for plaster with addition of lime is manufactured by mixing the dry mixture of sand and cement with a watery solution of lime.

Step by step instructions for creating a mixture of lime-based

The main binder component need to pound in a trough, in order to remove all lumps. After adding a little water and sand and again mix thoroughly. When a homogeneous dough is formed, per share pour lime 3 parts sand. Water was added as needed. Use of such a composition for plaster walls can be during the day, while it does not lose its main functions.

To accelerate hardening in the mixture may be added to gypsum plaster. It is important to consider a few rules: before, how to make a solution of, We need to divide sections, that can be seamlessly cover a short period of time. After all, within 6 minutes plaster solution sets and hardens completely.

If you make less dense solution, the hardening will be slow, but covered with turn loose and not so strong. Building plaster layer does not shrink, on this basis we can immediately hang wallpaper, that can not be said about the cement plaster.

Clay wall covering

Clay solution composition for plaster interior wall is made of alumina and sand. The basic "ingredient" pre-soaked with water, Further in the solution to pour sand and little water is added, for smooth mixing.

The dry plaster mixture

When buying dry mixes is important to consider several recommendations:

- Do not buy a mixture of plaster walls of an unknown manufacturer. It enjoys high popularity German firm "Knauf", the price of the products is somewhat higher, than for domestic products, but as a well-deserved. For low-cost plaster mixtures include the company "Strateli", "Eunice", "Osnovyt", "Volma".

- The walls of the foam better align plaster mixes, it absorbs moisture. Because the surface after the completion of the construction work necessary to repeatedly sprinkle water.

- The gypsum cement mixture of expensive, but first rate - 10 One kg sq.m., and second - 13-16.

- It is not necessary to buy the cement mixture for plastering of walls in large quantities, better to buy a few packs, and then buy another, in order to protect yourself from fraud.

- Plaster if not properly stored grasped within 10 minutes after mixing, and cement - will ramp up the wall.

How to prepare a base for plastering?

The thing is, that even the best plaster proper cooking may not "go" to the surface, if it is poorly cleared before applying the mixture. What to do?

Firstly, remove the old plaster poor, cleaned of old paint. Embroider seams masonry, voids and irregularities left as is.

Secondly, We cover the base primer and give time for drying. Next, prepare the mixture for finishing and proceed to spray solution.

Thirdly, within 40 minutes to perform final alignment.

ATTENTION! It is not recommended to work with a plaster mix in very hot weather, as well as in wet or frosty. Such indicators are significantly reduced material properties.

Plaster walls with cement mortar beacons

Plaster walls plaster solution is carried out with their hands on beacons, if there are significant shortcomings in the wall. In order to get a smooth surface, it is necessary to carefully monitor the application of the composition in the horizontal and vertical areas across the wall.

For better stucco wall on weak substrates, you need to use a grid plaster. Grids are metal and plastic.

The layer of deposited material should be at least 2 cm. the level needed for the construction of lighthouses, cord, plaster device, gypsum themselves metalloprofili. Beacons are installed at a distance 15-20 cm from the edge of the wall.

Now a solution to close up all the bumps and irregularities according to the invoice level. It is important to achieve a flat plane, both vertically, and horizontally. Be sure to dry the material and within a short period of time can be wall putty or other place decorative materials.

sophisticated technology, but if you follow all the rules of experts, perform her own hands possible. Bole, You will save a lot of money on the independent conduct of the procedure.

Thanks to all the advice of professionals, everyone can carry out both internal plaster without difficulty, and external surfaces, making his home beautiful wall, smooth, practical and durable.

Calculate the amount of material for plaster help calculator

Video on how best to plaster aerated concrete or foam block

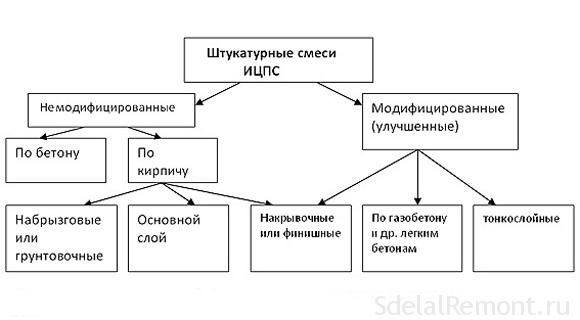

Dry mixes for plaster and versatile formulations

It is very convenient to use dry mixes for making plaster. To prepare the solution for plaster, enough to add a mixture of water and mix well. plaster solutions, prepared on the basis of dry building mixes, when used as exterior finishing, and at the inner workings. Plaster mixtures also, is used for leveling walls and ceilings. Thus the use of dry mixtures for finishing wall and ceiling surfaces, increases thermal insulation and soundproofing of premises. As well, plaster layers are the additional protection of building facilities from adverse natural phenomena.

Depending on, which is used in the dry mix filler (fine sand or coarse fraction), plasters are divided into fine and coarse. The size of grains of sand in the plaster mixture affects the method of applying the solution onto the surface of a wall or ceiling. Finely dispersed solutions have a greater plasticity, more convenient when working, and are more economical. Plasters, manufactured on a cement or cement-lime based, usually used for interior decoration wet and dry areas. It is very convenient for surface finishing gypsum plaster dry mixture, which are also very well fall on a ceramic brick.

surface, finished with a plaster, It turns out very smooth, whereby, It requires significantly less putties. Before starting the plastering work using gypsum dry mixtures, surface is necessary to prepare. approximately 15-30 minutes before the plaster, surface is moistened with water. Then stack leveling layers of plaster. After that, as a leveling layers harden, applied to them facing layers of plaster. If the previously laid layers have not dried up, and they cause facial layers, it can lead to the following defects. cracks, which were formed in the inner layers, It may extend to the outer layers. maybe, that the facing layer to previously deposited spolzot, but not the dried layer. Therefore, the need to apply layers of plaster on a solid surface. plaster places, to crumble, must be removed.

Universal mixture

Universal dry mixture used for finishing various surfaces. They are very convenient for the various types of repair and alignment of walls and ceilings, made of almost any building material. Universal mixtures can be applied for both internal, and external finishing works. The primary binder is a mixture of cement CPU brand 500 TO, and filler sand fraction.

Before application of the universal solution mixture, the surface must be cleaned of various contaminants and dust. Then, on the surface it is desirable to make incisions, for better grip surface with a solution of. Then the surface should be thoroughly wet with water. To prepare the solution of the dry mixture must universal mixture was poured into a container with water and mix well, until smooth.

The main thing all mixed in the right proportions. During repair, we use ready-made gypsum plaster, but it should prepare Curb. It is important to condition, not to do too much, tk. plaster quickly grasped and can simply not have time to develop it. It is necessary to observe the proportions of the mixture and water, if you get watery solution, make will not work with him. If you decide to make your own solution, not having ready-mixed, the risk of getting the wrong consistency increases, since the number of components increases.