- The general principles of the assembly process hammers Interskol

- Selection of lubricants

- Assembling impactor assembly unit

- tool receiver assembly

- Assembling countershaft

- the hammer assembly Assembling

- Assembling the keyless chuck SDS-plus

- Setting the mode switch knob

- stator assembly assembly

- Assembly Corps perforator Interskol P-26 / 800er

- Video assembly hammers Interskol

- Assembly perforator Interskol P-18 / 450ÉR

- Assembly perforator Interskol P-22 / 600er

- Assembly perforator Interskol P-26 / 800er

- Assembly perforator Interskol P-600er

- Assembly perforator Interskol P-710ÉR

Hammers in service sufficiently undemanding. should be replaced in a timely manner to maintain the operating state of the punch Interskol lubricant in the gearbox every time, are replaced when worn out carbon brushes of the electric motor.

The old grease is removed without fail, is preferred to remove the special detergent compositions, used in service centers. But handyman great cost solution of a mixture of kerosene and gasoline. Assembling the gun Interskol their own hands is a fairly simple process. It is only necessary to read disassembly instructions, scheme, Spare parts catalog.

Before assembly, prepare new or renovated and freshly washed details, new repair kit O-rings, lubricants, tools and auxiliary materials. Do not forget about the correct preparation of the workplace and lighting on him.

Stuffing the new lubricant is made on freshly washed and only the details, which is recommended for this node.

Laying new lubricant, do not overdo it: excess grease in the process of perforating often squeezed through the gearbox casing and lead to the destruction of seals.

Before assembling the parts to check the internal surface roughness. The surface should be polished to a mirror. With low roughness of the abrasion of rubber sealing rings is more intense. detail the repairs perforator Interskol.

The general principles of the assembly process hammers Interskol

Drifters Interskol assembly can be divided into several stages:

- Installing the rubber O-ring.

- Assembling the separate units.

- block assembly.

- Assembling electrical.

- Checking the power efficiency.

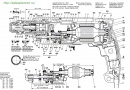

All drills Interskol consist of several large blocks:

- Mechanical shock assembly unit.

- an intermediate shaft unit.

- gear unit.

- stator unit.

- Block control circuits.

Selection of lubricants

special lubricants designed to lubricate rotary hammers domestic manufacturers. Lubrication is divided by units of work conditions. For the lubrication of gearboxes, rolling bearing and the clutch is recommended to use lubricants, specifically designed for these sites.

Conventionally lubrication are divided into three categories:

- For highly loaded nodes, such as the impact mechanism, reducer, countershaft.

- For lubrication shank drills.

- For the lubrication of rubber O-rings.

As the lubrication of rubber O-rings should be used Ciatim-221, does not destroy rubber.

specialty lubricants are used for perforating gears Interskol.

Before installation on the details of the rubber O-rings last it is necessary to lubricate the inert lubricant for rubber, withstand temperatures up to +120 oC.

It is recommended to use not only an inert lubricant for rubber, but also provides a high compaction at work. From domestic lubricants note Ciatim- 221.

For reliable capture tool, its easy retrieval at the end of the work it is recommended to apply a special bundle for shanks.

Assembling impactor assembly unit

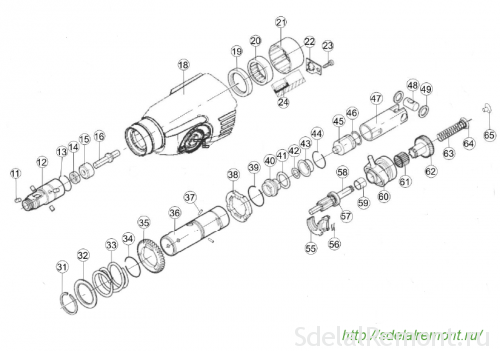

At percussive rock drill Interskol block assembly includes the barrel and the hammer parts.

shock node assembly consider the example gun barrel Interskol 26 / 800ER.

The firing mechanism consists of prommassy pos.16, trunk poz.37, poz.45 pin and piston poz.47.

The impactor momentum created by the reciprocating motion of the piston in the barrel poz.47 poz.36. Inside the piston moves the striker poz.45 and transmits a pulse on prommassu pos.16. But already prommassa transmits the impact impulse in the tool receiver position 12. In the above circuit, there is another device, a smoothing value of shock pulse on pin prommassu. The device is called the catcher pin poz.42.

the barrel assembly

On the trunk poz.36 worn gear poz.35, On the other hand poz.38 cam sleeve and the compound gear-cam sleeve fixed needle rollers and the retaining ring poz.37 poz.34.

The pinion is pressed against a spring poz.33, It is put on the trunk and all poz.32 washer fixed circlip poz.31.

The barrel is inserted into the body poz.18, in which the pre-inserted sleeve poz.19, poz.20 pressed roller bearing and sleeve poz.21.

the barrel assembly installed inside ends of the striker and the catcher after lubrication of internal surfaces. Installation of the barrel in the safety gear housing fixed lock ring.

piston assembly

Piston assembly poses. 47 begin with the installation of a poz.48 fingers and two rings poz.49. The finger acts as a leash on a rolling bearing poz.60. The firing pin plunger is inserted with a predetermined poz.45 sealing ring poz.46.

Before inserting the firing pin inside the piston, the inner surface of the piston should be checked for roughness. On the surface, there should be no traces of scratches.

Coat the inner surface of the piston with a thin layer Ciatim-221, Insert the firing pin inside.

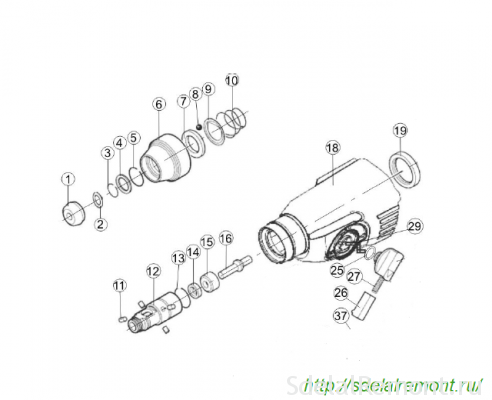

tool receiver assembly

The design Interskol perforator P-26 / 800ER working tool inserted in the receiver and a special tool clamped in the chuck.

It is simply a tool receiver position 12.

In the inner part of the receiver assembly is inserted into the assembled prommassy pos.16. On prommassu must first wear sleeve poz.15, cuffs pos.14, rubber ring pos.13. A rubber O-ring and the inside of the barrel assembly to the receiver necessarily promazhte lubricant Ciatim-221.

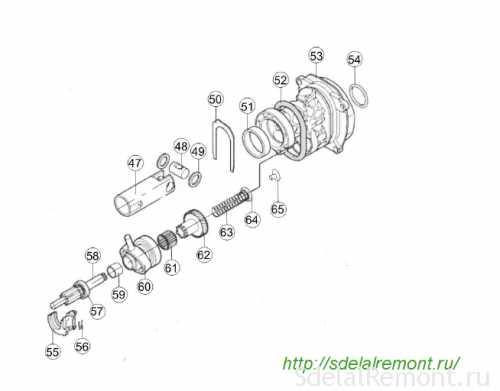

Assembling countershaft

The perforators Interskol P-26 / 800ER intermediate shaft is a complicated assembly.

The assembly of the intermediate shaft is not difficult.

First, gather a rolling bearing components opz.60. The bearing is inserted into the needle bearing and the wheel gear poz.61 combined poz.62.

The assembly is inserted into the body with simultaneous installation poz.53 poz.47 piston. Before installing the leash rolling bearing is inserted in the finger poz.48.

Mounted intermediate shaft fixed bracket poz.50.

the hammer assembly Assembling

In the next step the intermediate shaft mounted gear shaft poz.58 to put on it a lead switch poz.55.

The assembly is lubricated with grease for gearboxes.

You're on the piston barrel wear poz.36.

Grease lubricated recommended gear reducer and cover of the outer casing reducer poz.18.

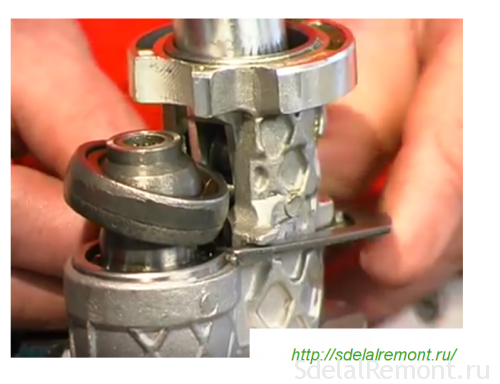

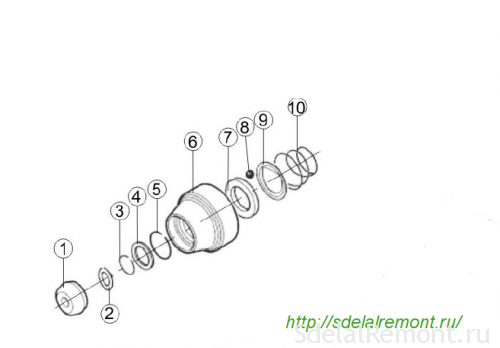

Assembling the keyless chuck SDS-plus

Clutching punch vertically mounted in a vise, Gather keyless chuck. Coat the inner barrel cavity, Tool insert receiver.

Align tools and barrel receiver, then insert the item 11 videos.

Top slide conical spring item 10, pos.9 special washer and insert the ball pos.8.

At the receiver tool wear ring pos.7, sleeve push pos.6. Lock construction circlip pos.5.

It remains to put the puck pos.4, lock the second locking ring pos.3.

Wearing washer pos.2, set the protective sleeve Item 1.

Setting the mode switch knob

Place the perforator Interskol on its side, to free access to the opening for setting of the mode switch knob.

The pen is simply. It is only necessary to get a mustache to switch slots. The handle is inserted into the position, opposite "impact drilling +", rotates and the fixed latch 15º, pressing the white button.

Installed button rotates clockwise to verify operation.

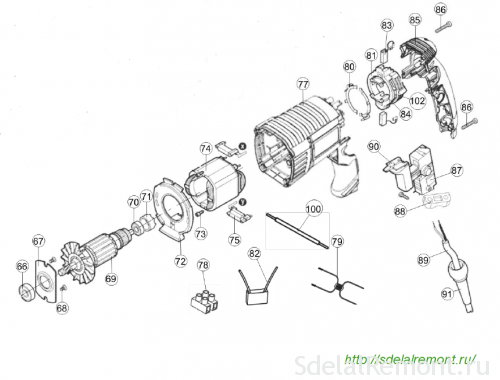

stator assembly assembly

The stator assembly Interskol perforator P-26 / 800ER no different from any other of the stator assemblies perforator.

The stator casing is inserted into the stator poz.74, screwed poz.73 and closes the diaphragm poz.72.

poz.69 rotor is inserted into engagement with the spur gear of the intermediate shaft.

Assembly Corps perforator Interskol P-26 / 800er

Assembling Interskol perforator P-26 / 800ER completes installing stator housing cover poz.77.

Install the brush holder and the carbon brushes

Fixing the housing cover, proceed to install the brush holder poz.81. Installation of the brush holder does not cause any difficulties.

The brush holder set carbon brushes poz.83, fix their pressing coil springs poz.84.

Stay insert button switch poz.87, connect the wires to the terminals of the stator, hide wires in the handle of the gun.

Checking performance Is perforator Interskol P-26 / 800er

After collecting punch Interskol, ensure easy turning the rotor shaft, scrolling through his instrument receiver.

Inspect correct and uniform contact of carbon brushes. Connect the instrument to the network 220 AT.

Turn briefly punch and check carbon brushes spark.

Install protective cover poz.85.

Everything!

Assembling other models of hammers Interskol virtually no different and is shown in the video below.

Video assembly hammers Interskol

Assembly perforator Interskol P-18 / 450ÉR

Assembly perforator Interskol P-22 / 600er

Assembly perforator Interskol P-26 / 800er

Assembly perforator Interskol P-600er

Assembly perforator Interskol P-710ÉR