- Принципы работы автоматики для систем водоснабжения

- Разновидности блоков электронных автоматики

- Важное значение автоматов защиты для водяных электродвигателей

- Выбор и настройка автоматов защиты

- Компоненты в системах Вводоснабжения

- Реле давления и принципы работы

- Датчик сухого хода

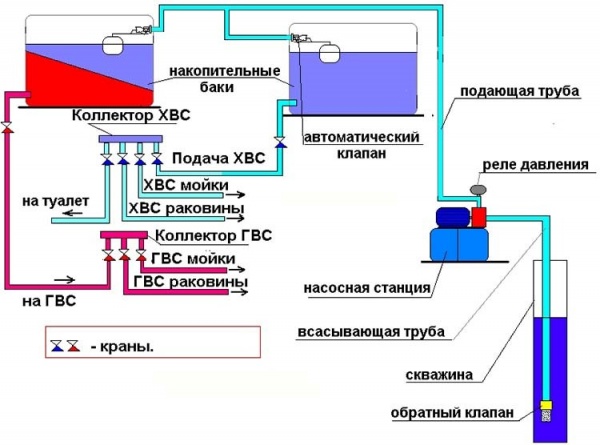

- Применение в системах водоснабжения

- Заключение

Системы водоснабжения являются частью современной работы, обеспечивающей надежные и эффективные системы подачи воды населению и предприятиям. Автоматика для систем водоснабжения играет ключевую роль в обеспечении эффективного и эффективном обеспечении таких систем. В данной статье мы рассмотрим принципы работы автоматики для систем водоснабжения и различные блоки электронных автоматики, которые используются для обеспечения надежности и эффективности водоснабжения.

Принципы работы автоматики для систем водоснабжения

Автоматика для систем водоснабжения – это комплексы технических решений и устройств, предназначенные для автоматизации и управления процессами подачи и распределения воды в домах, промышленных предприятиях, коммунальных предприятиях и других объектах. Основной целью автоматики в сфере домашнего водоснабжения является обеспечение стабильной и надежной подачи воды, оптимизация расхода воды, снижение энергозатрат и обеспечение безопасности эксплуатации. Вот ключевые компоненты автоматики, для системы водоснабжения https://www.allpromsnab.ru/catalogue/nasosy_i_motopompy/nasosy/dopolnitelnoe_oborudovanie/avtomatika_dlya_sistem_vodosnabzheniya/

Автоматика позволяет контролировать работу насосов, включать и выключать их в зависимости от уровня воды в резервуарах или давления в системе.

Автоматика для систем водоснабжения основана на использовании различных датчиков и устройств управления процессами водоснабжения. Основные принципы работы включают в себя:

- Параметры мониторинга : Датчики уровня воды, давления, температуры и другие параметры контролируют состояние системы. Например, датчики уровня воды в резервуарах определяют, когда вода достигает минимального уровня, и сигнализируют об этом.

- Анализ данных : Собранные данные передаются контрольным устройствам, таким как программные логические контроллеры (ПЛК) или микроконтроллеры. Эти устройства анализируют информацию и принимают решения о текущих действиях.

- Управление устройствами : Автоматически управляемые насосы, клапаны и задвижки регулируют поток воды и давление в системе в соответствии с заданными параметрами. Например, при низком уровне воды насос может быть включен для подачи дополнительной воды.

- Системы и управление : современные системы водоснабжения могут быть интегрированы в системы управления, что позволяет операторам наблюдать за работой системы в кратчайшие сроки и принимать решения удаленно.

Разновидности блоков электронных автоматики

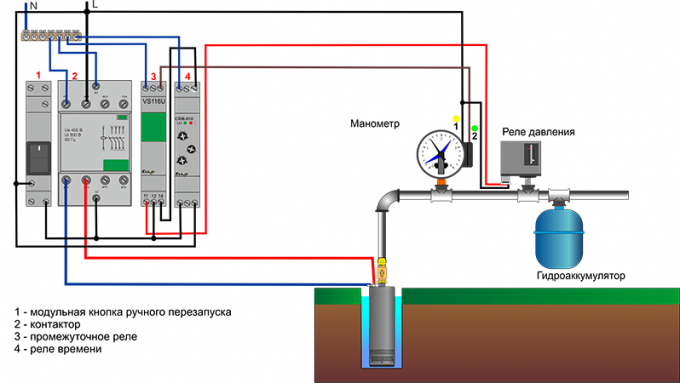

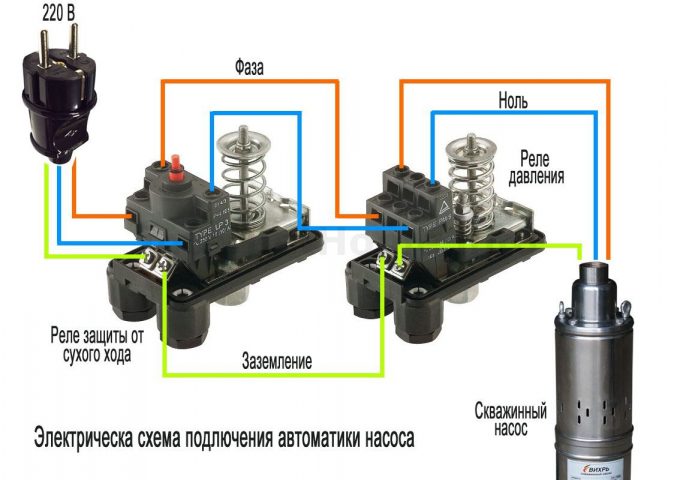

Для обеспечения эффективной и надежной работы управление водяными насосами в электроснабжении требует различных блоков электронной автоматики. Вот несколько подключений блоков электронных автоматики для управления водяными насосами

Для обеспечения надежности и эффективности технологических систем водоснабжения используются различные блоки электронных автоматов. Вот из некоторых из них:

- Блоки управления насосами : Эти блоки предназначены для управления работой насосов. Они могут включать и отключать насосы в воде в зависимости от производителя. Например, когда вода в резервуаре опускается до минимальной отметки, блок управления включает насос для подачи воды.

- Блоки управления клапанами и задвижками : Эти устройства контролируют положение клапанов и задвижек в системе. Они регулируют расход воды и давление в сети.

- Блоки параметров : Эти блоки включают в себя датчики для различных параметров , таких как уровень воды, давление, температура и качество воды. Они передают данные контрольным устройствам для анализа.

- Контрольные устройства (ПЛК и микроконтроллеры) : Эти устройства выполняют логику управления системой. Они анализируют данные от датчиков и принимают решения о работе насосов, клапанов и других устройств.

- Системы дистанционного управления : системы Эти позволяют операторам наблюдать за работой систем и принимать решения удаленно. Они могут включить в себя программное обеспечение и интерфейсы для системы управления через Интернет.

Важное значение автоматов защиты для водяных электродвигателей

Для обеспечения надежной работы и предотвращения аварийных ситуаций необходимо использовать автоматы защиты водяных электродвигателей. Водяные электродвигатели используются для подачи воды из резервуаров или скважин. Они могут работать в самых разных условиях, включая экстремальные температуры, давление и загрязнение. Однако в процессе эксплуатации существует ряд рисков, которые могут привести к повреждению оборудования и к аварийным ситуациям, таким как перегрев, перегрузка, короткое замыкание и другие неисправности.

Автоматы защиты разработаны для обнаружения и предотвращения этих рисков, обеспечивая безопасную и надежную работу водяных электродвигателей. Они выполняют несколько важных функций:

- Защита от перегрузки: Автоматы защиты мониторят ток, потребляемый электродвигателем, и могут автоматически отключить его, если ток превышает допустимые значения. Это предотвращает повреждение обмоток и других частей двигателя.

- Защита от перегрева: Перегрев может возникнуть из-за продолжительной работы двигателя при высокой нагрузке. Автоматы защиты мониторят температуру двигателя и отключают его, если температура достигает опасных значений.

- Защита от короткого замыкания: Короткие замыкания могут привести к серьезным повреждениям двигателя и системы. Автоматы защиты автоматически выключают двигатель в случае короткого замыкания.

- Защита от недостатка воды: Если уровень воды в резервуаре снижается до критической отметки, автоматы защиты могут отключить двигатель, чтобы предотвратить работу без воды, что может привести к серьезным повреждениям.

- 5. Защита от обратной фазы: Автоматы защиты также могут мониторить фазы электропитания и предотвращать работу двигателя в случае обратной фазы, что может привести к необратимым повреждениям.

- 6. Сигнализация о состоянии: Некоторые автоматы защиты оборудованы системами сигнализации, которые предупреждают операторов о возможных проблемах, таких как перегрузка или перегрев, путем включения индикаторов или отправки сигналов на удаленный мониторинг.

Выбор и настройка автоматов защиты

Выбор и настройка автоматов защиты зависят от конкретных требований и характеристик системы водоснабжения. Он включает в себя определение допустимых значений тока, температуры и других параметров, которые будут использоваться автоматами защиты для определения нормальной работы и аварийных ситуаций.

Важно также обеспечить правильное обслуживание автоматов защиты, включая регулярную проверку и калибровку, чтобы они могли правильно выполнять свои функции.

Автоматы защиты водяных электродвигателей играют ключевую роль в обеспечении надежности и безопасности систем водоснабжения. Они мониторят работу двигателей, предотвращают перегрузку, перегрев и другие потенциально опасные ситуации, что способствует продлению срока службы оборудования и снижению риска аварий. Оптимально настроенные и регулярно обслуживаемые автоматы защиты способствуют надежной работе систем водоснабжения и обеспечивают качественное водоснабжение потребителей.

Компоненты в системах Вводоснабжения

Системы водоснабжения сегодня стали частью нашей повседневной жизни. Их работоспособность и эффективность зависят от использования различных устройств и компонентов. Двуми необходимыми элементами, обеспечивающими надежную работу системы водоснабжения, являются реле давления и датчик сухого хода. В данной статье мы рассмотрим, как эти устройства влияют на работу систем водоснабжения и какие преимущества они носят.

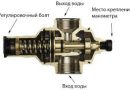

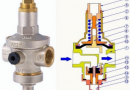

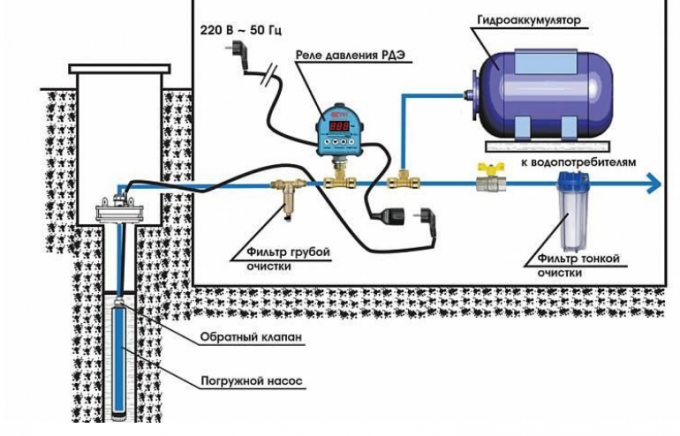

Реле давления и принципы работы

Реле давления – это устройство, предназначенное для управления в системе водоснабжения и управления насосами. Оно играет основную роль в поддержании необходимого давления в системе и предотвращении перегрузок. Вот принципы работы реле давления:

- Мониторинг давления : Реле давления использует датчики постоянного давления в системе водоснабжения. Это давление может определяться в зависимости от солнечного света, воды и других факторов.

- Параметры настройки : Пользователь может настроить желаемые параметры давления в соответствии с требованиями системы. Эти параметры определяют, когда насос следует включать и выключать.

- Управление насосами : Когда давление в системе опускается ниже установленного порога, реле давления активирует насос, чтобы поднять давление до желаемого уровня. Когда давление достигает установленного верхнего предела, насос выключается.

- Защита от перегрузок : Реле давления понижает работу насоса в режиме бесконтрольной перекачки воды, что может привести к его износу и повреждению.

Датчик сухого хода

Датчик сухого хода, или датчик включения воды, – это устройство, контролирующее наличие воды в системе и работу насосов, если вода отсутствует. Вот почему датчики сухого хода так важны:

- Предотвращение повреждений насосов : Насосы, работающие в режиме сухого хода, могут быстро перегреться и выйти из строя. Датчики быстрого хода помогут предотвратить этот негативный сценарий, отключив насос при недостатке воды.

- Сохранение электроэнергии : Работа насоса в пустом режиме потребляет электроэнергию, но не приносит пользы. Датчики быстрого хода позволяют экономить электроэнергию, отключая насос при отсутствии воды.

- Поддержание качества воды : Работа насосов в сухом режиме может вызвать попадание в систему воздуха и загрязнений, что может повлиять на качество воды. Датчик сухого хода помогает поддерживать чистоту воды.

Применение в системах водоснабжения

Реле давления и датчики дальнего хода применяются в различных системах водоснабжения:

- Жилые здания : Они обеспечивают стабильное водоснабжение и предотвращают нежелательные перебои в подаче воды в дома и квартиры.

- Промышленные системы : В промышленности они используются для эффективного управления большими объемами воды и обеспечения надежной работы насосных систем.

- Сельское хозяйство : Для сельскохозяйственных систем водоснабжения реле давления и датчики поступательного движения позволяют эффективно использовать водные ресурсы.

- Коммунальные системы : Водоснабжение и очистка сточных вод в средних коммунальных сетях требуют надежных устройств управления .

В заключение, реле давления и датчики сухого хода играют ключевую роль в обеспечении надежной и эффективной работы системы водоснабжения. Они позволяют предотвратить повреждение насосов, сэкономить электроэнергию и обеспечить постоянное качественное водоснабжение, что важно как для жилых помещений.

Заключение

Автоматика для систем водоснабжения играет решающую роль в обеспечении надежности и эффективности водоснабжения. Благодаря использованию элементов электронной автоматики и современных технологий, системы водоснабжения могут быть использованы для минимизации энергозатрат, увеличения потерь воды и обеспечения динамического водоснабжения помещений и предприятий. Автоматика для систем водоснабжения – это инженерное решение, которое реализовано более эффективно.