Верстаком можно назвать любой рабочий стол, который используется для обработки и изготовления изделий из различных материалов. Дополнительно стол может быть оснащен различными приспособлениями, которые облегчают ручной труд человека, самыми частыми из них являются тиски, а также упоры. К тому же под столешницей очень часто расположены полки, которые хранят в себе инструменты и всевозможные расходники.

Нормальная высота верстака составляет 80-90 сантиметров, а ширина столешницы редко превышает 1 метр. Длину же необходимо подбирать индивидуально, руководствуясь возможностями и габаритами человека и поставленных задач.

В продаже представлены профессиональные верстаки которые является устойчивая к нагрузкам и ударам. К примеру рассмотрим Sclad.ru — производитель металлической мебели разных назначений.

Делятся верстаки по предназначению всего на три группы, среди которых:

• столярные;

• слесарные;

• плотницкие.

Они имеют кардинальные отличия, начиная от общего и размера составных приспособлений и заканчивая особенностями, связанными с самой конструкцией. Каждая из групп действительно пестрит самыми разными моделями, которые могут удивить. Часто конструкцию делают таким образом, чтобы можно было все настроить, в частности, это касается высоты столешницы, что позволяет подогнать ее под рост человека.

Если упростить, то верстак – это рабочий стол, для работы с высокой нагрузкой и под конкретные работы .

Верстак должен соответствовать требованиям:

- прочным и надежным, чтобы выдерживать нагрузки, которые предполагает ваша деятельность;

- функциональным и эргономичным. Рабочее место должно отвечать росту мастера и при необходимости быть оборудовано местами хранения;

- устойчивым. На верстаке выполняются достаточно серьёзные работы, часто речь идет о больших нагрузках, при этом требуется высокая степень точности.

Именно поэтому рабочее место должно быть надежным и износостойким.

Слесарный верстак

Такой верстак является очень тяжелым, все дело в том, что основная часть его изготовлена из металла, а вот столешница из прочной и плотной плиты, выполненной из древесины (примерно от 30 до 50 миллиметров). Ее защиту обеспечивает лист из металла, толщина которого не превышает и 2 миллиметров. Это помогает предотвратить воздействие на плиту таких веществ как краска, бензин и так далее.

Верстаки из этой группы предназначены не только для того, чтобы осуществлять изготовление и обработку изделий, но и хранить в себе различные приспособления.

На одном из углов всегда находятся все те же тиски, без которых действительно никуда. Под столешницей же находятся отсеки, предназначенные для тех или иных вещей. Конструкция обладает хорошей устойчивостью, так как сделана из прочного материала.

Слесарный верстак чаще всего используется для того, чтобы работать именно с деталями мелких или средних размеров, поэтому лучшим расположением для него будет в углу или же под стенкой.

Очень часто закрепляется высокий щит, который необходим для закрепления на нем важных инструментов и других приспособлений. Такой щит не является обязательным, так как его функции может выполнять и любая вертикальная поверхность. Рекомендуется же его ставить, когда друг около друга расположены сразу несколько верстаков, в этом случае он будет выполнять функцию реального щита для защиты мастера.

К слесарным работам относят следующие процессы:

• рубка;

• сверление;

• полировка;

• опиливание;

• рихтовка.

Верстаки широко используются и для оборудования небольших производств, и на крупнейших заводах. Верстаки различаются комплектацией, так, есть верстаки однотумбовые, двухтумбовые, с полками и без полок. Также некоторые производители выпускают компактные верстаки, небольшого размера, которые используются и в столярном и в слесарном деле. Исходя из задач конкретного предприятия, подбираются верстаки оптимальной комплектации.

Кроме производства, слесарный верстак используется в учебных заведениях, а также в быту. Металлические верстаки практичны и долговечны.

Рассмотрим несколько серий с различными силовыми и размерными характеристиками:

Возможно произвести верстаки на заказ – изготовить нестандартные верстаки по индивидуальным размерам и пожеланиям.

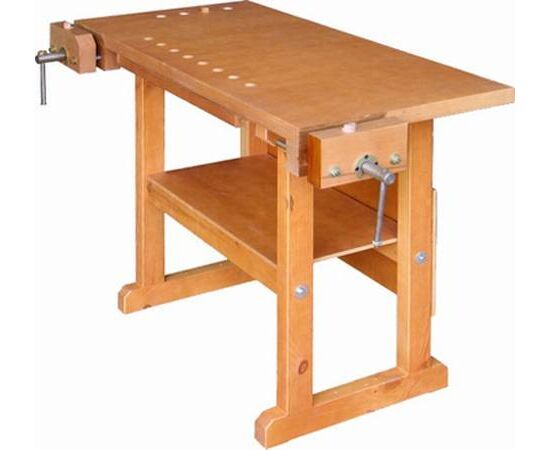

Столярный верстак

Такие столы делают из недорогой древесины, например, сосна. Главная особенность модели заключается в том, что для ее изготовления используются массивные бруски, которые скрепляются между собой клиньями или винтами. Для создания столешницы же используют более крепкие и долговечные древесные породы, например, дуб. 70 миллиметров – оптимальная толщина каждого бруска.

Краска обычно для столярных верстаков не используется, вместо этого их обрабатывают пропиткой. Главным приспособлением, расположенном на каждом таком столе, являются тиски, а столешница имеет несколько отверстий, необходимых для закрепления различных заготовок. Сами габариты столешницы могут быть разными, так как зависят от работ, которые будут проводиться на ней мастером. Конструкция и габариты позволяют устанавливать на поверхности верстака различные инструменты для обработки изделий, например, торцовочную пилу, рейсмус и так далее.

Столярный верстак по некоторым параметрам хуже слесарного, ведь он выполнен из дерева, а тот из металла, поэтому деформировать его гораздо легче. К тому же древесина боится влаги, а столярный изготовлен как раз для нее. Использовать его для покраски и обработки изделий не рекомендуется, так как он может легко запачкаться краской и другими подобными средствами.

К тем работам, которые выполняются только на столярном верстаке, можно отнести:

• разметка;

• склеивание;

• сборка;

• фанерование;

• обработка.

Данный тип верстака представляет собой идеальную промышленную мебель для оборудования рабочего места в школьной мастерской, гараже, на даче.

Плотницкий верстак

Такие же верстаки являются из всех самыми большими, но при этом конструкция у них до боли простая. Представляют они собой удлиненный стол, столешница которого имеет размеры 6×1 метров. Данный верстак необходим для того, чтобы выполнять строгание длинных заготовок. Стоит отметить, что верстаки именно этой группы гораздо сложнее приобрести в специализированных магазинах, так как они стали редкостью. Все дело в том, что все виды работ, которые выполняли именно на плотницком верстаке, на данный момент можно без особых проблем можно выполнить при помощи рейсмуса или фуганки.

Для изготовления каркаса всегда используются дешевые породы древесины, не обладающие достаточной твердостью, например, ель. Столешницу же наоборот делают из твердых древесных пород. Для пропитки поверхности могут использовать масло или различные пропитки. Чаще все такие модели не обладают полками, отсеками и шкафчиками для хранения инструментов и расходников.

На таких верстаках нельзя увидеть те самые вездесущие тиски, вместо этого для фиксации заготовок используется упор, вырез которого является треугольным. Ввиду больших размеров верстака, его очень сложно транспортировать, а также наличие его в мастерской не принесет особо ничего хорошего. На сегодняшний такие столы популярны только у тех мастеров, которые наносят художественную резьбу на удлиненных заготовках, необходимых для строительства бань, частных домов и других подобных сооружений.

В рамках плотницких работ выполняют следующие задачи:

• тесание;

• долбление;

• пиление;

• циклевание;

• резание.

Предложенная модель отлично приспособлена для профессиональной обработки деревянных заготовок в столярных и учебных мастерских.

Верстак не занимает много места и обладает отличным функционалом.