- Основные различия в конструкциях перфораторов Bosch

- Схема и конструкции перфоратора Bosch 2-20

- Конструкция промежуточного вала перфоратора Bosch 2–20

- Особенности конструкции перфоратора Bosch 2–24

- Конструкция промежуточного вала перфоратора Bosch 2-24

- Конструкция вала ствола ударного механизма

- Неисправности вала ствола ударного механизма

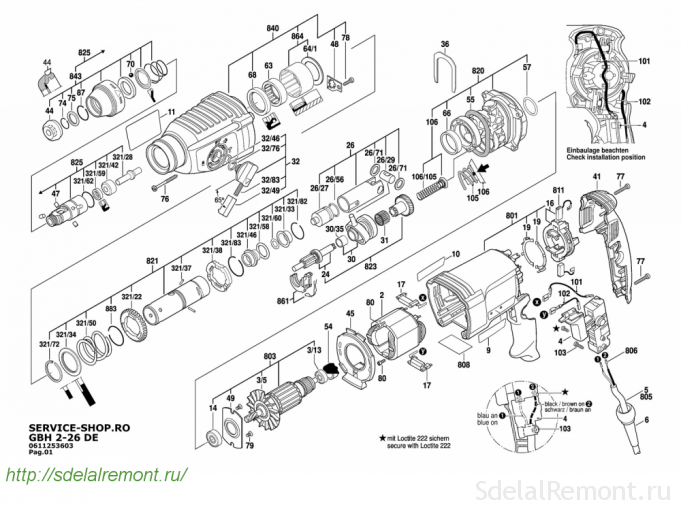

- Особенности конструкции перфоратора Bosch 2–26

- Конструкция вала ствола ударного механизма

- Выводы:

- Видео о разборки перфоратора Bosch

Наибольшее распространение среди профессиональных строителей России получили перфораторы Bosch, а среди любителей бытовые модели Bosch 2–20, 2–24, 2–26.

Перфораторы не только хорошо работают, но и легко ремонтируются. На них легко можно найти любую, вышедшую из строя деталь.

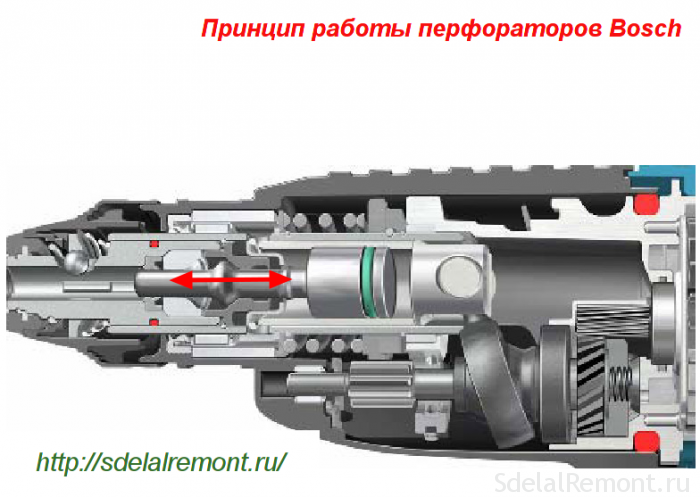

В конструкциях описываемых перфораторов заложен один и тот же принцип, передавать вращательный момент от ротора к валу ствола ударного блока с одновременной передачей поступательного импульса на рабочий инструмент.

Конструктивно перфораторы выполнены по одинаковой схеме, но отдельные узлы или детали имеют свои особенности.

Если знать специфические различия между моделями описанных перфораторов Bosch, то разборка и ремонт своими руками не составят особого труда.

Наряду с оригиналами на российском рынке присутствует большое количество подделок инструментов, включая перфораторы Bosch.

Ниже описаны конструктивные особенности моделей и способы их разборки и ремонта своими руками.

Принцип работы перфораторов одинаковый, а вот конструктивные особенности различаются.

Основные детали, используемые в перечисленных моделях перфораторов Bosch, взаимозаменяемы. Это касается механического и электрического узла.

Но есть узлы и делали, отличающиеся используемыми деталями.

Чтобы выполнить ремонт перфоратора Bosch 2–20, 2–24, 2–26, надо эти различия знать. Знание особенностей конструкции каждого перфоратора облегчает процесс ремонта, нахождения поломок и их устранения.

Конструкции перфораторов Bosch настолько простые, что позволяют выполнить несложный ремонт, практически своими руками и заменить любую деталь без обращения в сервисные службы. Надо обладать навыками сборщика, иметь элементарные знания электротехники и понимать принцип работы перфоратора.

Основные различия в конструкциях перфораторов Bosch

Ремонтируя перфоратор Bosch, вы не обойдетесь без электрической и схемы разборки инструмента той модели, которую собираетесь чинить.

Электрические схемы перфораторов Bosch 2–20, 2–24, 2–26 практически одинаковы. Хотя некоторые непринципиальные различия имеются.

А вот механические блоки комплектуются деталями, различающимися между собой конструктивно. Основные различия собраны в двух узлах: в промежуточном валу и валу ствола ударного блока.

Наибольшие различия представлены в конструкциях промежуточного вала, сборке «пьяного подшипника», в переключателе режимов. Непринципиальные особенности присутствуют в конструкциях ствола ударного блока, ударника, бойка.

Начнем с перфоратора Bosch 2–20.

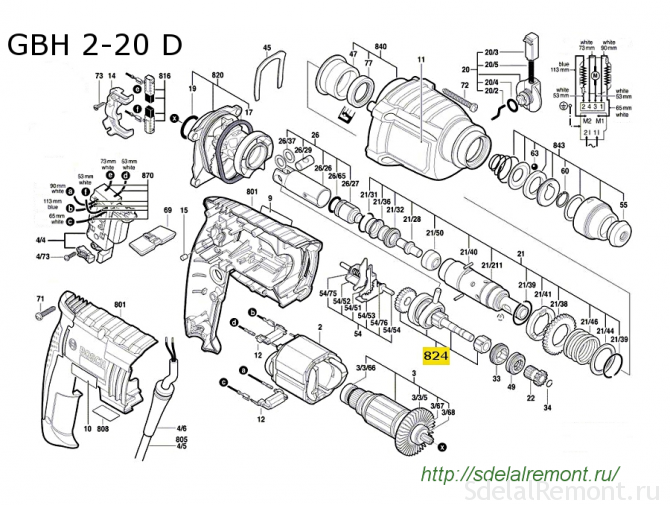

Схема и конструкции перфоратора Bosch 2-20

Ремонт перфоратора Bosch 2–20 не возможет без знания конструкции чинимого инструмента.

Принцип действия перфоратора Bosch 2–20 основан на передаче вращательного момента от вала ротора поз.3 к валу ударного блока поз.22 через промежуточный вал поз.824, одновременно передавая продольный импульс на рабочий инструмент.

Ротор поз.3 передает вращательный момент на шестеренку косозубую промежуточного вала поз.824.

Косозубая шестерня закреплена на промежуточном валу и передает момент вращения на вал. На валу закреплен пьяный подшипник, получающий момент вращения через муфту сцепления. За счет своей конструкции пьяный подшипник передает поступательное движение на цилиндр ствола ударного механизма.

Конструкция промежуточного вала перфоратора Bosch 2–20

Промежуточный вал перфоратора Бош 2–20 состоит из узла подшипника качения (пьяный подшипник), муфты сцепления, большой косозубой шестерни, малой прямозубой цилиндрической шестерни.

Чаще всего поломки проявляются в износе шлицов муфты сцепления, что приводит к пропаданию вращения патрона перфоратора при наличии ударного импульса.

Исправляется заменой муфты сцепления или восстановлением зубьев деталей муфты.

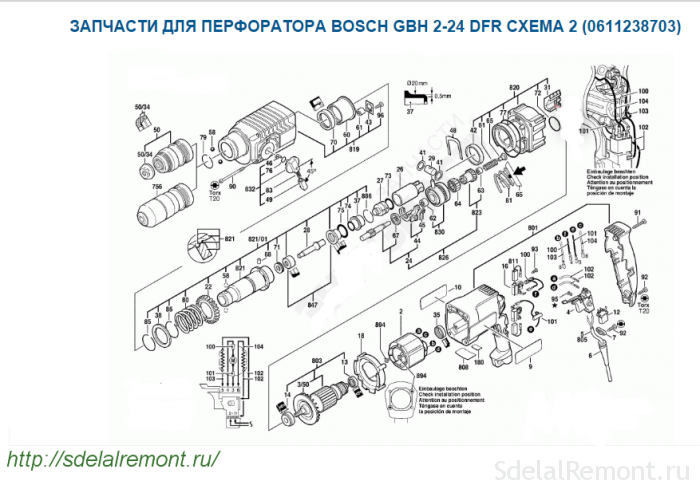

Особенности конструкции перфоратора Bosch 2–24

Ремонт перфоратора Bosch 2–24 лучше всего начинать со знакомства с схемой и конструктивных особенностей налаживаемого инструмента. Принцип действия перфоратора Bosch 2–24 аналогичен принципу действия перфоратора Bosch 2–20.

Вращательный момент передается на вал крепления инструмента, одновременно с передачей ударного импульса. У перфоратора предусмотрено три режима работы: сверление с ударом, сверление без удара, удар.

Косозубая шестерня ротора поз.803 передает вращательный момент на шестеренку косозубую промежуточного вала поз.826.

Конструкция промежуточного вала перфоратора Bosch 2-24

Промежуточный вал перфоратора Бош 2-24 состоит из узла подшипника качения поз.830, муфты сцепления поз.823, детали переключения поз.44. Чаще всего из строя выходит муфта сцепления. В ней изнашиваются зубья. Ремонт муфты заключается в исправлении профиля зуба зацепления в муфте и на промежуточном валу.

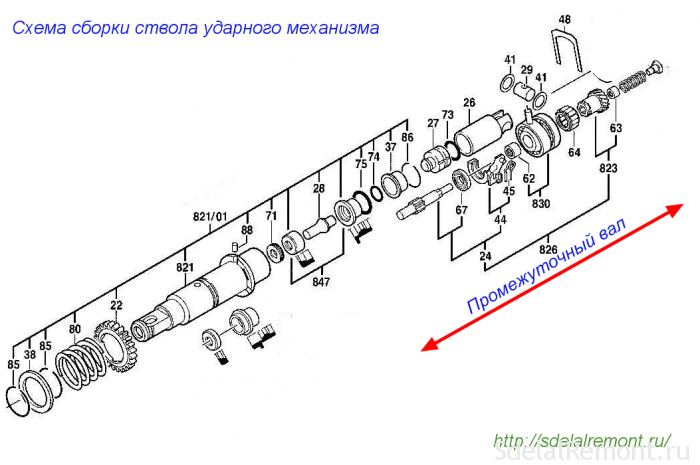

Конструкция вала ствола ударного механизма

Вал ствола ударного блока предназначен для передачи вращательного импульса с одновременным перемещением ударника.

Вращение передается от прямозубой шестерни промежуточного вала на большую прямозубую шестерню поз.22 вала ствола поз.821.

Возвратно-поступательное движение передается через пьяный подшипник поз.830, ударный поршень поз.26, боек поз.27, ударный болт поз.28 на закрепленный в патроне поз.756 бур.

Конструкция представляет собой вал, полый с одной стороны. На вал с двух сторон устанавливаются детали.

Со стороны крепления патрона на вал устанавливается прямозубая шестерня поз.22 и фиксируется на валу при помощи ролика поз.88, прижимается к буртику вала пружиной поз.80. Сама пружина фиксируется стопорным кольцом поз.85.

В полость вала ствола ударного блока вставляется: собранный ударный болт поз.28 и ударный поршень. В ударный поршень поз.26 вставляется боек поз.27 с поставленным на него новым резиновым кольцом поз.73. Все резинотехнические изделия смазываются рекомендуемой смазкой.

Неисправности вала ствола ударного механизма

Из–за ослабления силы пружины, выпадения фиксирующего ролика шестерня может проворачиваться на валу. Это проявляется в пропадании момента вращения с присутствием ударного импульса.

Перфоратор долбит, но не сверлит.

При износе резинотехнических изделий (уплотнительные кольца) перфоратор перестает работать в режиме «Долбление». Происходит это постепенно. Сила удара ослабевает по мере износа резиновых колец. Все дело в том, что от пьяного подшипника движение передается ударному поршню поз.26, в котором боек поз.27 создает давление воздуха и воздействует на ударный болт поз.28.

Перфоратор сверлит, но не долбит.

Если при работе перфоратора вы прилагаете большую силу, то это может привести к разрушению ударного болта, заклиниванию бойка в ударном поршне. Такие неисправности устраняются только полной заменой вышедшей из строя детали. Более подробно об устранении неисправностей перфоратора Bosch.

Особенности конструкции перфоратора Bosch 2–26

Ремонт перфоратора Bosch 2–26 следует начинать с ознакомления особенностей в конструкции налаживаемого инструмента. Принцип действия перфоратора Bosch 2–24 аналогичен принципу действия перфоратора Bosch 2–26.

Вращение передается от вала ротора, через промежуточный вал, на вал ударного ствола. Одновременно, закрепленный на промежуточном валу пьяный подшипник передает на ударный поршень возвратно–поступательное движение.

У перфоратора предусмотрено три режима работы: сверление с ударом, сверление без удара, удар.

Косозубая шестерня ротора поз.803 передает вращательный момент на шестеренку косозубую промежуточного вала поз.823.

Промежуточный вал аналогичен валу в конструкции перфоратора Bosch 2–24 и взаимозаменяем сам и деталями, входящими в состав промежуточного вала перфораторов Bosch 2–24, 2–26. Инструкция по разборки перфоратора Бош.

Конструкция вала ствола ударного механизма

Вал ствола ударного блока по конструкции аналогичен валу ствола перфоратора Bosch 2–24. К поломкам приводят неисправности тех же деталей, что и в перфораторе Bosch 2–24.

Особенности вала перфоратора Bosch 2–26 в том, что ведомая большая прямозубая шестерня поз.22 фиксируется на валу тремя штифтами поз.37, в отличие от фиксирующего ролика в перфораторе Bosch 2–26.

Выполняя разборку вала ствола ударного блока перфоратора Bosch 2–26, обращайте внимание на способ фиксации шестерни. Прежде чем снять шестерню, надо вынуть три штифта. Порядок правильной сборки перфоратора Bosch.

Выводы:

- Знание различий между приведенными моделями перфораторов Bosch позволит вам быстро выполнить разборку инструмента, заменить неисправные детали. Для этого вам не понадобится обращаться в сервисные службы.

- Конструктивно перфораторы Bosch настолько простые, что позволяют выполнять ремонт практически любой сложности.

- От вас требуется только наличие желания и элементарных знаний в механике.

Бывает, что попадаются поддельные модели перфоратора Bosch об этом более подробней.

Видео о разборки перфоратора Bosch