В процессе монтажа электропроводок, особенно в жилых помещениях приходится применять технологии соединения проводов и кабелей. Этот процесс требует некоторых навыков и знаний. Ведь неправильное соединение может привести к необратимым процессам. Может произойти нарушение работы общего электроснабжения, а также пожаров. Дело в том, что небрежно выполненное соединение многожильных проводов может привести к возникновению пожара, что в свою очередь приводит к угрозе жизни и здоровью людей. Требования к монтажу проводок в жилых домах прописаны в Правилах устройств электроустановок, сокращенно – ПУЭ. ПУЭ разрешает использовать в жилых помещениях электропроводки, выполненные только медными проводами. Соединение многожильных и одножильных проводов разрешается только методом опрессовки, сварки, пайки или с применением обжимов. В сжимах соединение производится механическим путем, с помощью винтов или болтов и клем.

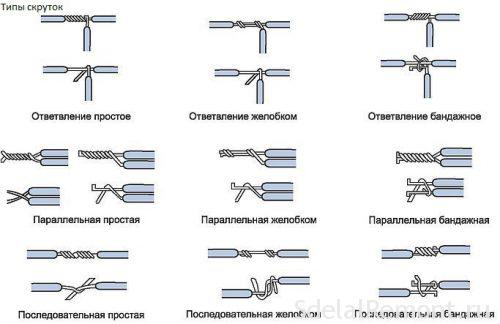

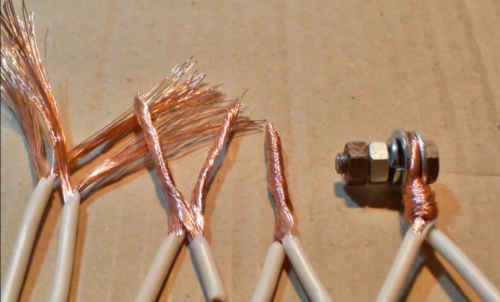

Различные варианты скруток

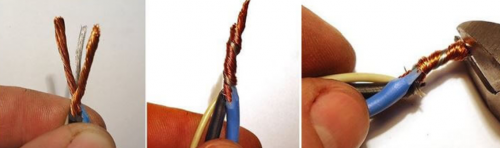

Непрофессиональное соединение. Это скрутка многожильного провода с одножильным. Такой вид соединений правилами не предусмотрен, и если такое соединение проводов будет обнаружено приемной комиссией, то объект просто не будет принят в эксплуатацию.

Скрутка многожильного медного провода в распаренной коробке применяют, как промежуточную операцию перед пайкой или сваркой места соединения и обязательно требуется паять или произвести обжимные соединения.

Однако скрутку все же применяют и тут нужно знать как выполняется правильная скрутка многожильных проводов. Она часто используется в экстренных случаях, когда нет возможности профессионально выполнить соединение, и срок эксплуатации такого соединения будет небольшим. И еще, скрутку временно можно применять только для открытых проводок, чтобы можно было всегда осмотреть место соединения.

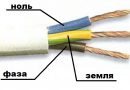

Почему же нельзя соединять провода скруткой? Дело в том, что при скрутке создается ненадежный контакт. При прохождении через скрутку токов нагрузки, место скрутки нагревается, а от этого увеличивается переходное сопротивление в месте соединения. Это в свою очередь способствует еще большему нагреванию. Таким образом, в месте соединения повышается температура до опасных значений, которая может вызвать пожар. Кроме того, нарушение контакта приводит к появлению искры в месте скрутки, что тоже может вызвать пожар. Следовательно, чтобы достичь хорошего контакта рекомендуется скруткой соединять провода сечением до 4 мм2. Подробно про о цветовой маркировке проводов.

Существуют несколько типов скруток. При скрутке необходимо добиваться хорошего электрического контакта, а также создания механической прочности на разрыв. Прежде чем приступать к соединению проводов их следует подготовить. Подготовка проводов осуществляется в следующей последовательности:

- с провода, в месте соединения снимается изоляция. Изоляция снимается таким образом, чтобы не повредить жилу провода. Если на жиле провода появится надрез, то в этом месте он может сломаться;

- оголенное место провода обезжиривается. Для этого оно протирается тряпкой, смоченной в ацетоне;

- для создания хорошего контакта, обезжиренный участок провода зачищается наждачной бумагой до металлического блеска;

- после соединения должна быть восстановлена изоляция провода. Для этого может применяться изоляционная лента или термоусаживающаяся трубка.

На практике применяются несколько видов скруток:

- простая параллельная скрутка. Это самый простой и распространенный вид соединения. При хорошей параллельной скрутке в месте соединения можно добиться неплохое качество контакта, но механические усилия на разрыв будут минимальными. Такая скрутка может ослабевать в случае возникновения вибрации. Чтобы правильно выполнить такую скрутку необходимо, чтобы каждый провод обвил друг друга. При этом должно быть не менее трех витков;

Скрутка обычная двух проводов

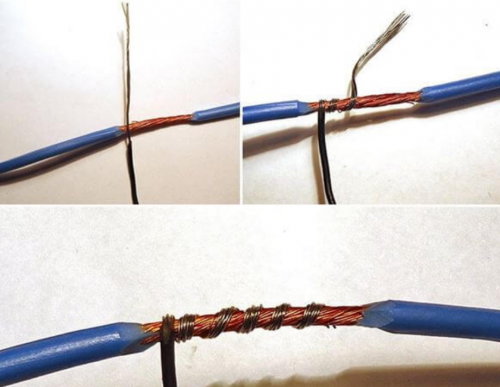

Многожильная скрутка трех проводов - метод «навивки». Этот метод применяется, если необходимо выполнить ответвление провода от основной магистрали. Для этого на участке ответвления снимается изоляция провода, и на оголенное место путем навивки подключается провод ответвления;

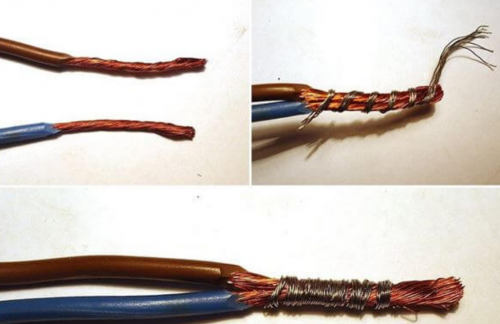

- бандажная скрутка. Этот вид скрутки часто применяется при соединении двух и больше одножильных проводов. При бандажной скрутке применяется дополнительный проводник из такого же материала, как и жилы провода. Сначала выполняется простая параллельная скрутка, а затем на это место накладывается бандаж из дополнительного проводника. Бандаж увеличивает механическую прочность на разрыв в месте соединения;

- соединение многожильного и одножильного провода. Этот вид самый распространенный и простой сначала выполняется простая накрутка, а затем зажимается ;

- другие различные варианты соединения.

Подробно, о методах соединения одножильных проводов https://sdelalremont.ru/nadezhnye-sposoby-soedineniya-elektricheskix-provodov.html

Профессиональное соединение

Рассмотрим различные варианты надежного соединения по технологи: пайки, обжима, сварки и клеммного соединения проводов. Вы откажетесь от ненадежной скрутки при монтаже распаянных коробок и прочих соединениях.

Пайка проводов

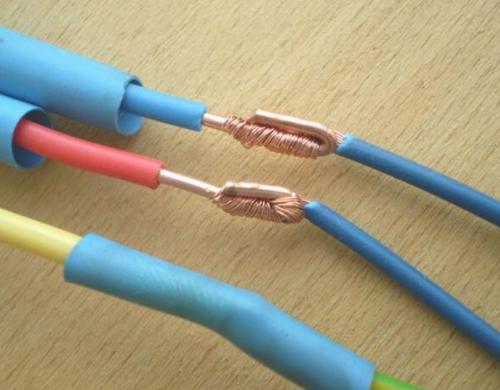

Соединение медных многожильным и одножильных проводов методом пайки относится к одному из надежных методов. При таком соединении создается хороший электрический контакт, а место соединения механически устойчиво к нагрузкам на разрыв. Этот метод может применяться при: сращивании двух повредившихся проводов, удлинении проводов, переносе розеток или выключателей. Соединенные таким образом провода, можно применять в скрытых проводках. Если хорошо изолировать место соединения, то такой провод не уступает цельному участку.

Технология такого соединения следующая:

- подготовка проводов производится в такой же последовательности, как и перед началом скрутки;

- очистка до металлического блеска участков проводов;

- покрытие припоем мест соединения (облуживание);

- провода соединяются одним из видов скрутки;

- соединенные скруткой провода пропаивается припоем;

- место пайки обрабатывается наждачной шкуркой. В месте пайки не должно быть заусенцев, которые могут повредить изоляцию;

- место соединения тщательно изолируется.

Соединенные таким образом провода можно размещать под штукатуркой. Для надежности, место соединения следует поместить в поливинилхлоридную трубку.

Метод сварки

Сварка относится к категории неразъемных соединений. Этот вид наиболее надежный. Именно при этом способе участок соединения приобретает монолитность. Сопротивление контакта и механическая прочность участка соединения ничем не отличается от цельного провода. Сварка осуществляется как на постоянном, так и на переменном токе.

Для профессиональной сварки проводов применяются различные типы сварочных аппаратов, но наиболее широкое применение получили аппараты инверторного тока. Данные аппараты мобильны, они легко переносятся на плече электромонтера, отличаются небольшими габаритами.

Инверторные аппараты отличаются широким диапазоном регулирования рабочего тока. Сварочная дуга легко зажигается даже при малых рабочих токах, и устойчива в процессе всего периода сварки.

Кроме сварочного аппарата для сварки медных проводов необходимо иметь еще и угольные, покрытые медью электроды.

Технология сварки состоит из нескольких простых операций. Для начала с провода удаляется изоляция. Затем, по технологии, изложенной выше, выполняется скрутка проводов. Скрученные провода выравнивают путем обрезки их торцов. Чтобы не перегреть провода и их изоляцию, необходимо в процессе пайки отводить тепло. Для этого применяется специальный зажим, который подключается к одному из полюсов сварочного аппарата. Сварка осуществляется путем прикосновения к торцам проводов рабочего электрода, который удерживается в сварочном держателе, подключенном к другому полюсу сварочного аппарата.

Опрессовка

При опрессовке, провода помещаются в специальные монтажные гильзы, которые выполнены из такого же материала, что и провода. В данном случае из меди. Затем гильзы сжимаются специальным инструментом. При сжатии гильзы происходит деформация проводов, Деформируясь, провода плотно сжимаются друг с другом. При местном вдавливании, провода деформируются таким образом, что их отдельные точки проникают в тело друг друга. Таким образом, создается надежный электрический контакт, и место соединения становится механически прочным. Опрессовкой соединяют провода, которые помещаются в распределительных коробках и электрических шкафах.

Для выполнения опрессовки применяются специальные монтажные клещи. Для соединения проводов при монтаже проводок в жилых помещениях широкую популярность получили опрессовочные клещи модели ПК-16. Для соединения медных проводов применяются соединительные медные гильзы типа ГМ. Они изготавливаются из меди и имеют красный цвет.

Для того чтобы место соединения не контактировало с кислородом, его консервируют специальным техническим вазелином. Таким образом, изолируется место соединения от вредных действий окружающей среды. Провода не будут окисляться, и соединение прослужит длительное время. Место соединения можно еще герметизировать термоусаживающей трубкой.

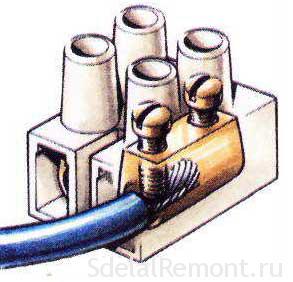

Резьбовоесоединение

Этот вид соединений соединение одножильного и многожильного проводов относится к категории разъемных соединений. Для этого применяются специальные клеммники, состоящие и корпуса и встроенных в них устройств, предназначенных для винтового зажима провода. Обязательно для надежного соединения провод общать или залудить . Наиболее широкое применение получили при соединении концевых потребителей. (светильников и люстр)

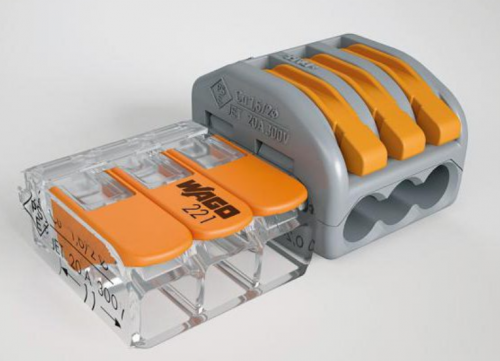

Самозажимной клемник

Применяется для соединения проводов сечением не более 2,5 мм2. С помощью клемника такого типа можно одновременно соединить до 8 проводов. Они применяются для соединения проводов в электрических шкафах. В основном используется для световой разводки. В розеточной группе при больших нагрузках применяйте более надежные варианты соединения.

Винтовые клемники

Этот вид клемников относится к самым востребованным устройствам. С их помощью соединяются только медные провода. Благодаря своим небольшим габаритам они используются при соединении проводов в распределительных коробках.

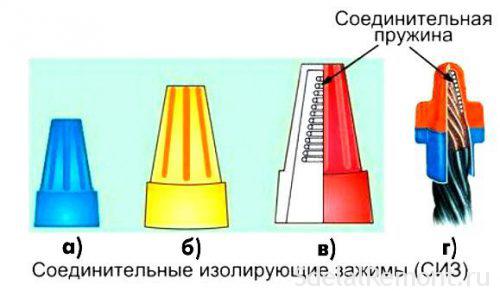

Изолирующие зажимы (СИЗ)

Эти зажимы применяются для соединения проводов небольших сечений до 25 мм2. Конструкция зажима состоит из корпуса, выполненного из пластмассы. Внутри корпуса расположена пружина, имеющая форму конуса. Чтобы соединить провода, их сначала соединяют скруткой в пучок, а затем на него накручивают зажим. Провода соединяются путем удержания их пружиной. Место соединения не требует дополнительной изоляции, так как корпус колпачка выполнен из изоляционного материала.