Планируя независимое водообеспечение, хозяин дома в Московской области должен узнать некоторые особенности этого дела.

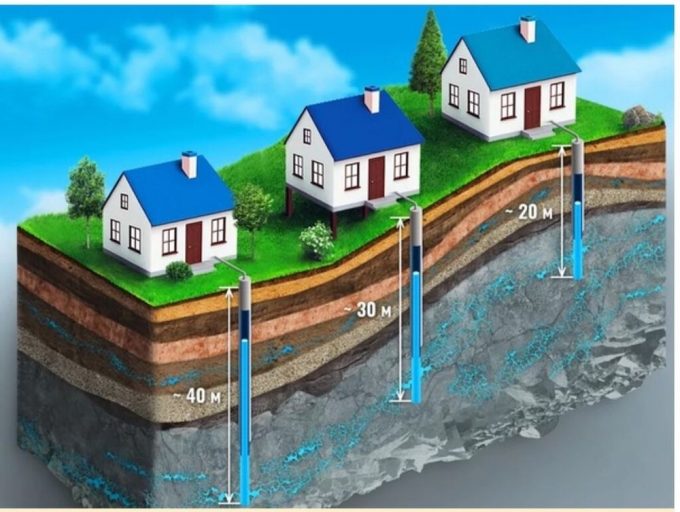

В пределах Подмосковья имеются песчаные и известковые водоносные горизонты. На слоях этих пород можно оборудовать 2 вида скважин: фильтровые и артезианские. Фильтровые делают недалеко от поверхности земли (до 30 м глубиной) и вода здесь есть относительно недолго (от 5 до 15 лет). Зато артезианскую скважину бурят до уровня известкового водоносного слоя, глубиной от 20 до 200 м. Продолжительность эксплуатационного срока на артезианскую скважину достигает до 50 лет.

Прежде чем решить, какую скважину бурить, должна быть выполнена оценка запасов подземных вод. По этим итогам владелец дома может выбрать оптимальный для себя вариант. Артезианские воды очищаются природным способом, проходя через многочисленные слои грунта. Благодаря этому не возникает заиливание. Это основная причина, почему нельзя пользоваться хранилищем.

Любая скважина с достоинством выдержит свой гарантийный срок, если бурение будет выполнено лучшим современным оборудованием. Конечно, работники должны быть профессионалами в своем деле, тогда все получится по высшему разряду, например компания ГлавБурВод.

Для получения фильтровой воды лицензирование скважин не нужно выполнять. Зато пользование артезианской водой, залегающей ниже первого водоносного слоя, невозможно без соответствующих документов. Владельцам земли лучше начинать оформление одновременно с бурением, чтобы успеть к окончанию работ. Без этих документов невозможно провести контрольный забор воды и запуск всей системы.

Для больших владений, где и огород, и дом, большой расход воды. В таких случаях нужна артезианская скважина стоимость которой выше фильтровой скважины. Эта разница возникает не только из-за наличия документов. Артезианская водная артерия в десятки и сотни раз мощнее фильтровой. Также диаметр отверстия труб больше и оборудуются дополнительные обсадные колонны.

Очень важно, что качество воды в этих двух видах тоже значительно отличается. Артезианскую можно пить без предварительной очистки, а из фильтровой – разве что огород поливать. Учитывая, что артезианская скважина глубина которой может достигать несколько сотен метров, нуждается в оснащении мощным насосом, то и цена становится выше. Такое количество преимуществ артезианской воды прямопропорционально стоимости работ.

Конечно, без качественных труб, надежных переходников и кранов даже правильно пробуренная скважина функционировать не станет.

Шнековое бурение скважин: на что обращать внимание?

Достаточно часто водные скважины сооружают, используя шнековое бурение. Оно выполняется с помощью лопастного резца: деталь измельчает и выбирает грунт. Разрушаемая ею земляная твердыня извлекается на поверхность ямы, освобождая скважину. Бурение скважин шнеком подобно манипуляциям рыбаков с зимним льдом. В ледяной толще они сверлят скважины стандартными дурами.

Оборудование на базе шнека подходит в случае, когда необходимо пробурить на суглинистых, глинистых и супесчаных почвах неглубокую скважину высотой не более 80 м и диаметром до 25 см.

Особенности бурильного процесса

Когда шнек вращается, порода под воздействием буровой коронки смещается вслед за поверхностью винта и движется вверх. Ее подача наверх осуществляется непрерывно. Благодаря этому шнековое сооружение очень производительно. В течение смены удается пробурить, как правило, до 50-60 м, реже до 200 м земной толщи. Когда бурение скважин производится шнеком, промывать их не требуется. Поэтому буровые работы возможны и зимой, и на лишенной воды территории.

Особенности бурового снаряда

На первой схеме вы можете видеть, как действует снаряд. Здесь обозначены: скважина, шнековый элемент, коронка бура и грунт. Минусы бурения скважин шнеком это:небольшая глубина скважинной шахты;ограничение в использовании в зависимости от грунта: он должен быть мягким;извлечение лишь структурно поврежденных образцов породы.Основа шнека – трубы из стали, к которым приваривается лента также из стали в виде винта.

Чтобы соединить трубы, по одну сторону к ним прессуют втулку с отверстием-шестигранником, по другую крепят сваркой хвостовик с шестью гранями. И у одного, и у второго шестигранника есть отверстия, которые совпадают и в которые помещается крепежная деталь. Фиксатор на пружине удерживает ее от выпадения. Звено шнека варьируется по размеру и бывает от 1,3 до 3 м в длину, от 12 до 20 см в диаметре. Спираль винта выполняется с шагом 0,7-0,8 доле от диаметра шнека.Коронку шнека используют, чтобы разрыхлить породу. По величине она на 2 см превышает диаметр шнека. Коронку составляет трехлопастной корпус из стали. В него впаиваются твердосплавные резцы. Их припаивают и к ободку снаружи. Такая конструкция дает возможность точно придерживаться скважинного диаметра. Коронковый замок устроен, как и на шнеках (вы можете видеть на второй схеме коронковый корпус, спиральный элемент, деталь-фиксатор, твердосплавные пластины). Кроме коронки-переходника нередко при бурении шнеком используют долото, которое среди бурильщиков известно как рыбий хвост.

Стандартное оборудование для бурения

При бездорожье, чтобы увеличить проходимость, шнековое бурение проводят с помощью установки УШБ-Т, которую монтируют на прицепе трактора. Установка для буровых работ с возможностью переноса (ПБС-110) способна функционировать лишь в мягкой земляной породе. Для ее работы нужен автономный токопроводящий генератор: шнековый привод вращается под действием тока. Когда проводится бурение скважин с помощью шнека, особенно разведочное, часто используют бурильную установку ПБС-110 с возможностью переноса.

Итак, шнековое бурение возможно и оправдывает себя при буровых работах на мягком грунте. Они позволяют бурить скважину глубиной до 80 м в любое время года и даже там, где местность лишена воды. Зная об этом, вы можете оценить, насколько технология бурения шнеком подходит для вашего случая.

Подготовка скважин и фильтры для скважин на воду к работе

После того как, пройдя водоносный горизонт, скважина доходит до нижнего водоупорного слоя, наступает время ее подготовки к работе. Подходить к этому делу следует очень внимательно, ведь грамотная и тщательная подготовка скважин к работе позволяет долгое время добывать чистую воду без проблем и ремонта.

Прежде всего, перед вводом скважин в эксплуатацию их тщательно очищают желонкой*. Такая подготовка позволит впоследствии свободно опустить фильтр, которым должна обладать любая скважина для воды. После очистки необходимо измерить расстояние от верхнего настила и до самого дна водоносного слоя. Затем в водоносный слой на колонне водоподъемной трубы опускают фильтр.

Обратите внимание: фильтр должен опускаться без закрутки, свободно и легко. Теперь пространство, которое образовалось между стенками скважины и фильтром следует засыпать крупнозернистым очищенным песком или мелкозернистым гравием. Одновременно с засыпкой следует медленно поднимать колонну обсадной трубы на высоту фильтра. Засыпка также будет принимать участие в очистке воды.

Со временем любые фильтры для скважин на воду засоряются, и поэтому их нужно время от времени вынимать и промывать.

После того как вы извлечете фильтр, снова проведите очистку от засыпки при помощи желонки и опустите его на место. Не забудьте снова засыпать вокруг фильтра свободное пространство.

Фильтр для скважин на воду

Безусловно, фильтр является важнейшим элементом всех водоподъемных скважин. Главная его задача заключается в защите водоподъемной трубы от песка, который в водоносном слое присутствует всегда.

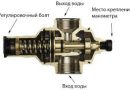

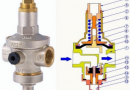

Непосредственно фильтрацию воды обеспечивает специальная металлическая сетка с ячейками нужного размера. Сама сетка опирается на каркас, который должен защищать ее от деформации (смятия).

Фильтр на воду конструктивно выглядит как перфорированная труба, вокруг которой с некоторым зазором обмотана металлическая сетка. Сам зазор обеспечивается редкой проволочной навивкой.

Обратите внимание, что это не единственная существующая конструкция фильтра.

Устройство фильтра для скважин на воду

1 — трубка;

2 — перфорация;

3 — навивка для зазора;

4 — металлическая сетка.

*Желонка — специальная цилиндрическая посудина. Служит для вычерпывания на поверхность жидкости и разрушенной породы, песка и грязи во время бурения скважины, а, кроме того, для очистки от песчаной пробки. Помимо этого с ее помощью при освоении скважин берут пробы жидкости.