Вытяжка стала почти обязательным элементом оборудования домашней или профессиональной кухни. Благоприятный микроклимат в зоне приготовления пищи и соседних помещениях, создаваемый при ее работе, давно оценили домашние хозяйки и повара. От правильного выбора оборудования, трубы для вентиляции на кухне, материала для ее изготовления зависит качество работы всей системы воздухоотвода.

Функции, виды, выбор вытяжного устройства

Важность вытяжки в месте приготовления пищи очевидна, ведь ее основные задачи:

- отвод из рабочей зоны воздуха, загрязненного продуктами сгорания, дымом, испарениями, запахами;

- снижение влажности и температуры воздуха у плиты для более комфортной работы;

- обеспечение условий, препятствующих появлению и размножению нежелательных микроорганизмов;

- увеличение долговечности кухонной мебели, бытовых приборов и предметов интерьера, на которые не будут оседать копоть, жир и грязь;

- обеспечение притока чистого воздуха вместо отведенного с загрязнениями;

- создание комфортных условий для работы на профессиональных кухнях и благоприятного проживания в частных владениях возле помещения кухни.

Вытяжка соединяясь трубами воздуховода с шахтой вентиляции, помогает удалению загрязненного воздуха наружу.

На кухнях устанавливают вытяжки следующих видов: плоские, наклонные, встраиваемые, Т-образные, островные, угловые, купольные, телескопические.

Для отвода всего объема загрязненного воздуха размеры вытяжки обязательно должны совпадать или быть больше, чем у варочной поверхности. Минимальная производительность (м3/час) вытяжного оборудования должна минимум в 10 раз превышать объем помещения кухни.

Рекомендуемая высота установки вытяжки:

- над газовой плитой – 0,75-0,85 м;

- над индукционной или электрической плитой – 0,65-0,75 м.

Выбор трубы для вытяжной системы

Для продуктивности и надежности работы всей конструкции отвода загрязненного воздуха большое значение имеет выбор трубы под вентиляцию. Рассмотрим основные критерии.

Материал применяемых труб

Гофрированные трубы из алюминия – самый дешевый и простой в монтаже вариант для организации отвода загрязненного воздуха от вытяжки. Основой трубы являются металлические кольца. Их обтягивает в несколько слоев ламинированная фольга. Первоначально кольца находятся в прижатом друг к другу положении, верхняя оболочка сложена в «гармошку». При монтаже гофра способна удлиняться в несколько раз, изгибаться под требуемым углом. Поэтому она легко прокладывается в стесненных условиях и труднодоступных местах.

Не полностью растянутая гофрированная труба становится источником характерного шума вытяжной системы из-за увеличенного сопротивления неровностей внутренней поверхности воздушному потоку. Уровень шума также повышают дополнительные изломы трубы.

Гофрированные трубы для вентиляции выдерживают значительный нагрев (до +250°С), обладают значительной прочностью, стойкие к воздействию агрессивных сред, при необходимости наращиваются (для соединения используется металлический скотч), могут прослужить до 50 лет.

Вытяжные системы из пластика обладают рядом достоинств, которые делают их лидерами потребительского спроса:

- Малый вес позволяет смонтировать всю систему одному человеку, не требует дополнительного крепежа или поддерживающих элементов, исключает дополнительную нагрузку на подвесные модули кухонной мебели.

- Высокая устойчивость к воздействию многих химических соединений и влаги.

- Отличная герметичность воздуховодов при высокой прочности смонтированной конструкции.

- Устойчивость к воздействию ультрафиолета.

- Простота и легкость в уходе, доступность и дешевизна необходимых моющих средств.

- Способность работы системы при температурах широкого диапазона.

- Создание хорошей звукоизоляции, не нарушающей комфортного пребывания в помещении с вытяжной системой.

- Долговечность.

- Впечатляющий ассортимент пластиковых элементов вытяжного трубопровода различных форм и размеров, из различного материала: полипропилен, полиуретан, поливинилхлорид.

- Эстетичный строгий вид собранной системы.

- Простота монтажа позволяет собирать из стандартных фасонных деталей надежные вытяжные конструкции.

- Пластиковые элементы трубопроводов не подвержены коррозии, их материал является экологически безопасным.

- Гладкая внутренняя поверхность труб не позволяет скапливаться грязи и жиру.

- Вытяжные системы с пластиковыми трубами (особенно круглого сечения) практически бесшумные, в сравнении с воздуховодами из других материалов.

Пластиковые трубы дороже гофрированных. Их монтаж более сложный, требует наличия дополнительных переходных и соединительных элементов. После сборки трубопровода остаются неиспользованные обрезки. Это основные недостатки пластиковых труб.

Форма и размеры сечения трубы

Гофрированные трубы имеют круглое сечение, пластиковые – круглое или прямоугольное. Меньшим сопротивлением обладают трубопроводы из круглых труб, за что пользуются популярностью. Прямоугольные трубы смотрятся эстетичнее, их проще собирать и можно располагать у самой стены.

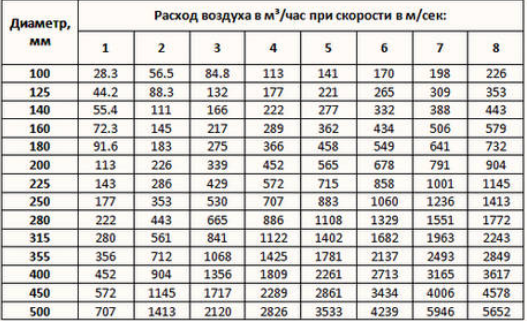

Наиболее часто применяют следующие трубы:

- Круглые, диаметр (мм): 100, 120 – обычно указываемый в инструкции диаметр вентиляционной трубы для вытяжки; 125 и 150 – также часто применяются пользователями.

- Вентиляционные прямоугольные трубы для вытяжки имеют следующие размеры, высота х ширина (мм): 55х110, 60х122, 60х204.

Важно! Для эффективного воздухоотвода размер сечения трубы вентиляции должен совпадать с площадью выходного патрубка вытяжки или быть больше (тогда потребуется соединение через переходной элемент).

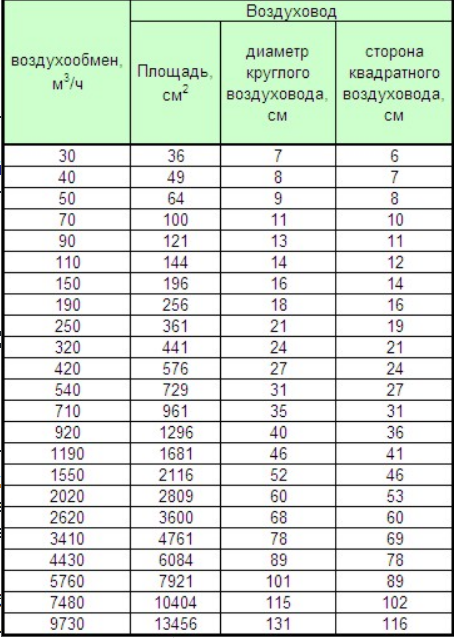

Калькулятор необходимой производительности вентиляции для вытяжки на кухне

Если вам необходимо рассчитать вентиляцию для жилых помещений воспользуйтесь онлайн калькулятором производительности воздухообмена.

Важные особенности монтажа

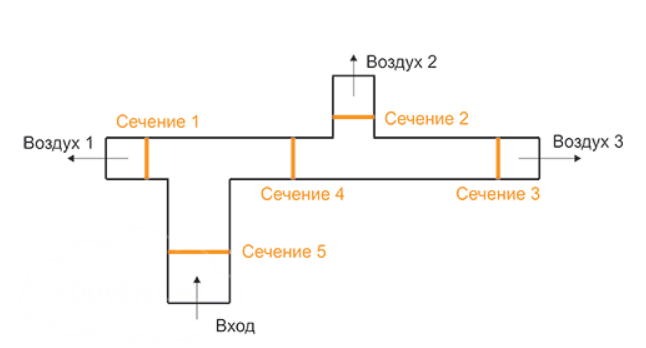

Ошибки при сборке и монтаже приточного вытяжного трубопровода могут перечеркнуть предыдущие старания по правильному подбору вытяжки, расчету необходимого сечения применяемых труб, выбору необходимых переходных и соединительных элементов. Чтобы вытяжная система работала правильно, следует обратить внимание на такие моменты ее монтажа:

- Собранная конструкция трубопровода не должна иметь прогибов. Если устанавливается гофрированная труба – ее растяжка должна быть максимальной.

- Вся вытяжная система должна заземляться для отвода статического электричества.

- Чтобы не повредить воздухоотвод при его прохождении через стены, используются специальные переходники и гильзы.

- Места всех соединений (между трубами, трубы и вытяжки, трубы и переходника вентиляционной шахты) обязательно должны быть обработаны герметиком.

- Загибы гофрированной трубы до радиусов, которые меньше диаметра применяемой гофры, снизят давление и, следовательно, эффективность работы системы отвода воздуха.

- Оптимальный трубопровод вытяжной системы имеет минимум изгибов и поворотов, его длина – до 3 м, углы изгибов – тупые.

- При большой длине воздуховода из гофры, через 1-1,5 м его необходимо фиксировать хомутами для предотвращения возможного раскачивания при работающей вытяжке.

- Для соединения трубопровода с полостью вентиляционной шахты используйте специальную рамку с решеткой для приточной вентиляции, фланцем для крепления трубы и обратным клапаном. При работе вытяжки клапан закрыт и не допускает попадания загрязненного воздуха обратно в помещение. Когда вытяжка не работает, клапан открыт – происходит свободная циркуляция воздуха.

Поворот трубы под острым углом или на 90° неизменно понизит производительность всей системы на 10%. Несколько таких изломов сделают ее работу малоэффективной, хотя вытяжное оборудование будет работать с перегрузкой. Если нельзя изменить линию пролегания трубы, желательно увеличить ее сечение и мощность вытяжки.

Маскировка элементов вытяжной системы

Даже аккуратно смонтированная вентиляционная труба для вытяжки может не вписываться в дизайнерскую концепцию помещения или слишком привлекать к себе внимание. Если трубопровод собирался из оцинкованных элементов или алюминиевой гофры – он будет отлично сочетаться с общим стилем «хай-тек». Во всех остальных случаях конструкцию нужно маскировать или декорировать. Часто способом маскировки служат:

- Потолки (натяжные, подвесные). Они также могут скрывать элементы других инженерных коммуникаций.

- Специальный короб из пластика или гипсокартона.

- Монтаж трубопровода в подвесную кухонную мебель.

- Специальные фальшпанели, закрывающие проходящие коммуникации. Они устанавливаются или крепятся на подвесные шкафчики и декорируются под кухонный фасад либо под отделку прилежащих стен.

Правильно смонтированная вытяжная система из грамотно подобранных комплектующих является залогом комфортного и безопасного приготовления пищи.