- Свойства газобетонных блоков

- Газобетон как основной строительный материал

- Выбор связующего состава

- Какой толщины стоит возводить перегородки

- Технология построения перегородки из газобетонных блоков

- Подготовка основания

- Монтаж блоков на раствор

- Применяем клей

- Почему лучше использовать клей

- Процесс укладки блоков

- Делаем дверной или оконный проем

- Окончание монтажа

Перегородка представляет собой отличное техническое конструктивное средство, которое позволяет из одного большого помещения сделать много маленьких, или даже просто зонировать комнату, разделив ее на определенные функциональные части. В зависимости от размещения к ней предъявляются разные требования:

- Прочность. Должна быть крепкой и устойчивой, материалом для таких перегородок может стать газовый блок стеновой, кирпич, пазогребневые плиты и керамзитобетонный блок.

- Должна обладать хорошими звукоизоляционными свойствами. Здесь предпочтение стоит отдавать пористым и воздухосодержащим материалам.

Но создавая перегородку в квартире или доме, следует учесть прочность основания, на котором она будет располагаться. На железобетонных перекрытиях стенки вне опор возводить из кирпича не рекомендуется, так как из-за её достаточно тяжелого веса может произойти нарушение в целостности всего здания. Не говоря уже о деревянных перекрытиях, где даже такой легкий и пористый материал, как пеноблок или газобетон, не стоит укладывать. В таких условиях тогда лучше использовать гипсокартон или дерево.

Свойства газобетонных блоков

Самым оптимальным решением как по стоимости, так и по создаваемой нагрузке являются газобетонные перегородки. Материал, из которого они построены, обладает следующими свойствами:

- Отлично выдерживает большие нагрузки на сжим. На данное свойство газобетона указывает его плотность, которая выражается цифрами D200, D300, D400, D500, D600. Она указывает на твердость материала и допустимые нагрузки, которые он способен выдержать. Но при этом с ростом плотности теплоизоляционные свойства ухудшаются. Межкомнатные газобетонные перегородки лучше выстраивать из D500 или D600, потому как теплоизоляция в принципе не актуальная, а прочность должна быть высокой, чтобы на стену можно было еще прикрепить мебель.

- Хорошо удерживает тепло. Это свойство обеспечивается за счет содержания большого числа газовых шариков (пор). Они могут образовываться в двух случаях. Когда присутствует катализатор (пенообразователь), а блок при этом запекается в печи. И второй способ – без применения вспенивателей, а блок затвердевает при нормальных условиях, но тогда этот материал хоть и имеет схожий химический состав, называется пенобетон. Но о нем поговорим в следующей статье. Газобетонная перегородка может стать отличным изолятором холодного помещения от теплого, создавая в нем оптимальный микроклимат за счет пористости.

- Стена из газобетонных блоков не выделяет токсинов, ядовитых испарений и прочих вредных веществ. К тому же газобетон не горит и не деформируется даже при длительном воздействии на него высокими температурами. Отсюда вытекает еще одно свойство – безопасность.

Газобетон как основной строительный материал

Газобетон уже давно используется в строительстве различных зданий любого назначения, потому что легко подвергается дальнейшей обработке. В него можно закрутить саморез, забить гвоздь, строгать обычной стамеской и даже пилить ножовкой по дереву.

Но за пройденное время технология изготовления претерпела некоторые изменения. Блоки стали идеальных геометрических размеров, идентичны друг другу, в одном ассортиментном ряду выпускаются с пазами и гребнями для облегчения и упрочнения их монтажа.

Если ранее монтаж газобетонных перегородок сводился к строганию боковых поверхностей, оштукатуриванию слоем до 5 см, то сегодня стена из газобетона практически готова к шпаклёвке и оклейке обоями после её возведения.

Выбор связующего состава

Сегодня существует несколько мнений о том, какой раствор следует применять для монтажа блоков:

- Некоторые говорят, что лучше использовать по старинке известковый раствор. Может это и так, потому что он теплее, чем просто песчаный и при этом при полном высыхании и малом содержании цемента имеет белый вид. Но у него есть отрицательная сторона – он очень хрупкий. Если используется такой раствор, то армирование каждого слоя необходимо выполнять в обязательном порядке. Он лучше годится для построения толстых стен, а не перегородок.

- Специальный цементно-песчаный клей. Он содержит пластификатор и затвердитель, что позволяет его намазывать тонким слоем, обеспечивая практически бесшовное соединение блоков. Именно поэтому рассмотрим, как класть газоблоки на клей.

Но первым делом его необходимо купить. Продается он в бумажных мешках, на которых написано «Клей для газоблоков». Можно также применять плиточный клей, он имеет те же свойства.

Какой толщины стоит возводить перегородки

Перегородка из газобетонных блоков может иметь самую разную толщину, зависящую от ожидаемых от нее свойств. Если она должна стать частью несущей конструкции, то необходимо применять блок не менее 200 мм толщиной и плотностью от D400. Для простого разграничения пространства достаточно и 100 мм.

А вообще, в продаже имеются все возможные типоразмеры, которые только могут пригодиться в строительстве, с помощью пеноблоков возможно возвести и обыграть различные конструкции.

Технология построения перегородки из газобетонных блоков

Любая работа должна выполняться качественно, поэтому предлагаем вам данную инструкцию о том, как класть газоблоки, фото процесса которого перед глазами. Отдельно рекомендуем ознакомиться со статьей Как штукатурить пеноблоки и газоблоки правильно.

Подготовка основания

Перед рассмотрением технологии, как правильно класть газоблоки, следует подготовить основание. Оно должно быть очищено от пыли и выступающих элементов, старого раствора, загрунтовано, при необходимости выполнена предварительная стяжка.

Отклонения от уровня более 3 мм могут привести к неудобствам дальнейшей работы.

Хоть блоки и производятся машинным способом на автоматической линии, но все же они будут иметь отклонения от геометрии. Поэтому обязательно приобретите специальную терку для газобетона. С ее помощью можно будет легко избавляться от наплывов, торчащих элементов блока и выступающих углов.

После очистки основания можно начинать монтаж газобетонной перегородки, но перед этим необходимо нанести контрольную разметку, по которой будет осуществляться укладка каждого из рядов. Можно использовать строительный трассировочный шнур, лазерный уровень или прикрепить направляющие бруски к стенам и полу. Благодаря им будет выдерживаться идеальная геометрия по краям перегородки, а при помощи шнурка − и по середине.

При укладке первого и последующего рядов монолитно забрасывать щель стыковки перегородки и основной стены не рекомендуется в целях повышения звукоизоляционных свойств. Её лучше позже заделать монтажной пеной.

Монтаж блоков на раствор

Сейчас немного поговорим о том, как класть блоки на раствор. В этом способе имеются и преимущества. За счет толстого первого слоя можно выровнять не совсем ровную поверхность уже вместе с блоками.

Но в дальнейшем смесь мажут на все контактируемые поверхности тонким, не более 2 см, слоем, периодически замазывая с двух сторон швы.

Применяем клей

Теперь рассмотрим подробнее, как класть газоблоки на клей. Он представляет собой ту же смесь из песка и цемента, но содержит специальный пластификатор и склеивающее вещество, что позволяет уже на следующий день прикладывать значительные нагрузки на стены. Для работы с клеем потребуется специальный мастерок с зубчиками и размерами блока. Это позволит не только быстрее и качественнее выполнить обмазочные работы, но поможет сэкономить клей на потерях.

Вооружившись мастерком, шпателем, теркой и уровнем, можно приступать к работе. Укладывать блоки начинаем от стены или от угла заворота перегородки. Если поверхность ровная, то достаточно наносить тонкий слой клея. Кладка газоблоков должна осуществляться ровно и качественно, поэтому после монтажа каждого из них их следует тщательно измерять со всех сторон и контролировать сход с ориентировочным шнурком.

Почему лучше использовать клей

Кладка газобетонных блоков на клей обеспечивает большую прочность и устойчивость стены за счет глубокого проникновения клеящей смеси, образуя тем самым монолитный шов. А тонкий, практически отсутствующий шов решает такую проблему, как островок холода, делая стену еще более теплой.

Процесс укладки блоков

Установка перегородки из газобетонных блоков осуществляется следующим образом:

Немного отступив от стены (примерно 5 мм), устанавливают первый блок, тщательно ровняя его по закрепленным брускам и трассировочному шнурку на предварительно намазанный равномерно тонким слоем клеящий состав.

Кладка перегородок из газобетонных блоков должна осуществляться качественно, для этого применяется обсадка блока на место. Эту операцию можно выполнить при помощи резинового молотка или накладки на него. Инструментом со всех сторон обсаживается блок и уровнем контролируется его приобретенное место.

Также возможен монтаж перегородок из газобетонных плит с пазами и гребнями. Они выпускаются тех же типоразмеров, что и гипсовые плиты, но обладают немного отличными от них свойствами.

Укладка газобетонных блоков далее повторяется до проема или до крайней стены с отступом от нее также в 5 мм в целях повышения звукоизоляционных свойств.

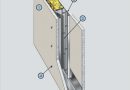

Каждый ряд из перегородки толщиной 100 мм следует армировать и связывать с несущими стенами или другими перегородками. Это можно выполнить при помощи кусков арматуры диаметром 6 мм и более. Для этого в стене на уровне угла блока еще до его монтажа на место сверлится отверстие на 1/2 длины арматуры. Сама же она может быть 15-20 см. В газобетонном блоке для перегородок при помощи стамески или ручного штробореза выбирается соответствующий паз для свободного проникновения в него арматуры.

При монтаже на место в отверстие в стене и паз накладывается тот же раствор для кладки газоблоков и замуровывается в него связка. Такое армированное соединение обеспечит необходимую прочность перегородке, независимо от ее толщины. При использовании блоков 150-200 мм скрепление со стенами можно делать через ряд. Также необходимо учесть перевязку между самими блоками, смещая последующие ряды на 1/2 толщины блока.

При монтаже на место в отверстие в стене и паз накладывается тот же раствор для кладки газоблоков и замуровывается в него связка. Такое армированное соединение обеспечит необходимую прочность перегородке, независимо от ее толщины. При использовании блоков 150-200 мм скрепление со стенами можно делать через ряд. Также необходимо учесть перевязку между самими блоками, смещая последующие ряды на 1/2 толщины блока.

Также в качестве связки можно использовать перфорированный уголок, шину и саморезами или гвоздями крепить ее к обеим поверхностям. Но такой способ является менее прочным по сравнению с первым.

Делаем дверной или оконный проем

Перегородка из газобетонных блоков имеет небольшой вес (1 монолитный блок размерами 600х300х100 мм и весом 10,5 кг заменяет 8 кирпичей весом 24 кг) по причине пористости используемых кладочных материалов, поэтому дверные проемы и арки шириной до 80 см можно выполнять без перемычек. Для этого достаточно класть блоки с перекрытием на стены по 20 см, плотно стыкуя их вместе по центру проема. Для их временной поддержки можно использовать каркас из деревянных брусков, прикрученный саморезами к блокам на уровне их укладки.

Устройство газоблочных перегородок с проемами шириной более 80 см требует обязательного использования перемычек. В качестве них может быть армированный монолит из бетона, два уголка по краям и даже деревянный брус, предварительно обработанный антисептическим составом.

Устанавливая газобетонные перегородки, монтаж их следует производить не до самого потолка. Рекомендуется оставлять пространство в 1-1,5 см. Его лучше заполнить монтажной пеной. Это делается для того, чтобы исключить растрескивание краев перегородки при вибрации потолка и обеспечить лучшие звукоизоляционные свойства. Подробнее читайте, как нужно штукатурить пеноблоки.

Окончание монтажа

После возведения перегородки из газобетонных блоков следует тщательно проверить ее на наличие просветов в швах и при помощи того же клея их заделать шпателем. После полного застывания клея (не менее суток) и перед дальнейшей обработкой стены из газобетонных блоков необходимо обработать антисептиком, препятствующим развитию в них грибков и прочих вредителей. Стену можно возвести и из гипсоблоков, более подробно об этом можно узнать на сайте в разделе стены.

«При возведении стен зданий из ячеистого бетона существует проблема разной теплопроводности самих стен и клеящего раствора. Через швы кладки происходят значительные потери тепловой энергии, (до 10% при использовании тонкослойных клеев, до 30% при использовании цементно-песчаных растворов), что приводит к увеличению расходов на отопление». Одним из решений по улучшению теплоизоляционных свойств кладки из газобетонных блоков является использование клея для ячеистого бетона теплоизоляционного торговой марки Gemisch. Главным отличием клея для ячеистого бетона теплоизоляционного торговой марки Gemisch от традиционно применяемых клеев является его высокая теплоэффективность, коэффициент теплопроводности клея Gemisch всего 0,202 Вт/(м*К), что практически соответствует теплопроводности самих блоков, т. е. в результате применения клея Gemisch мы получаем практически монолитную стену, и отсутствие «мостиков холода»