Полусухая стяжка пола — это современный и популярный метод выравнивания оснований для укладки напольных покрытий. В отличие от традиционных способов, полусухая стяжка обеспечивает быстрое высыхание и высокую прочность, что делает её предпочтительным выбором для многих строителей и домовладельцев. В этой статье мы рассмотрим, что представляет собой полусухая стяжка, её преимущества, процесс укладки, а также особенности и рекомендации производства полусухой стяжки пола под ключ.

Что такое полусухая стяжка пола

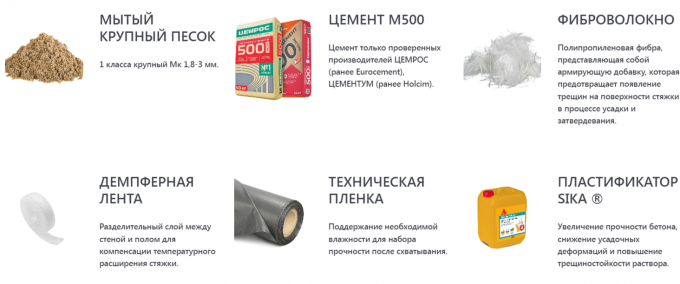

Полусухая стяжка пола — это разновидность цементно-песчаной стяжки, в состав которой добавляется минимальное количество воды. Этот метод позволяет добиться быстрого высыхания и высокой плотности стяжки, что является её главным преимуществом. Состав смеси включает цемент, песок и воду в соотношении, позволяющем получить плотную и маловлажную массу. Для повышения прочности и пластичности могут добавляться фиброволокно и пластификаторы.

Преимущества полусухой стяжки пола

Полусухая стяжка пола имеет ряд существенных преимуществ по сравнению с традиционными методами:

- Быстрое высыхание: Благодаря минимальному количеству воды в смеси, полусухая стяжка быстро высыхает, что позволяет приступить к дальнейшим работам уже через 24–48 часов после укладки.

- Высокая прочность и долговечность: Полусухая стяжка образует плотную и прочную поверхность, которая устойчива к механическим воздействиям и не подвержена растрескиванию. Это делает её идеальной основой для различных напольных покрытий.

- Ровная поверхность: Полусухая стяжка позволяет добиться идеальной ровности основания, что упрощает укладку финишных покрытий, таких как ламинат, плитка, паркет или ковролин.

- Минимальная усадка: За счет небольшого количества воды в составе смеси усадка стяжки практически отсутствует, что предотвращает появление трещин и деформаций.

- Улучшенная тепло- и звукоизоляция: Полусухая стяжка обеспечивает хорошую тепло- и звукоизоляцию, что особенно важно при устройстве полов в жилых помещениях.

- Удобство в работе: Процесс укладки полусухой стяжки более удобен и требует меньше трудозатрат, так как смесь легко укладывается и разравнивается.

Технология укладки полусухой стяжки пола

Процесс укладки полусухой стяжки пола включает несколько этапов, каждый из которых требует тщательного соблюдения технологии:

- Подготовка основания: Основание, на которое будет укладываться стяжка, должно быть очищено от мусора, пыли и остатков старого покрытия. При необходимости поверхность грунтуется для улучшения сцепления.

- Установка маяков: Маяки устанавливаются на основании для контроля уровня стяжки. Обычно для этих целей используют металлические профили, которые закрепляются на растворе или с помощью специальных креплений.

- Приготовление смеси: Смесь для полусухой стяжки готовится из цемента, песка и минимального количества воды. Оптимальное соотношение компонентов — 1 часть цемента на 3–4 части песка. Важно добиться такой консистенции смеси, при которой она будет влажной, но не жидкой.

- Укладка стяжки: Приготовленную смесь укладывают на подготовленное основание и разравнивают по маякам с помощью правила или специальной рейки. Полусухая смесь позволяет формировать плотную и ровную поверхность без лишних усилий.

- Уплотнение и затирка: После укладки смесь уплотняют с помощью виброплиты или затирочной машины. Это обеспечивает дополнительную прочность и плотность стяжки. Затем поверхность затирается, чтобы достичь идеально ровного слоя.

- Сушка и уход: Полусухая стяжка требует минимального времени на высыхание, но в первые несколько дней рекомендуется увлажнять поверхность для предотвращения слишком быстрого высыхания и появления трещин. Через 24–48 часов можно приступать к укладке финишного покрытия.

Особенности и рекомендации

Полусухая стяжка пола — универсальный метод, который подходит для различных типов помещений и оснований. Однако для достижения наилучшего результата важно учитывать следующие особенности и рекомендации.

Оптимальная температура для укладки полусухой стяжки — от +5 до +25 °C. При низких температурах процесс высыхания может замедлиться, а при высоких — возникнуть риск быстрого испарения влаги и растрескивания.

Рекомендуемая толщина полусухой стяжки — от 40 до 80 мм. При укладке на полы с подогревом толщина стяжки должна быть не менее 50 мм для равномерного распределения тепла.

Добавление фиброволокна в смесь улучшает прочностные характеристики стяжки, снижает риск трещинообразования и повышает долговечность.

Перед укладкой стяжки на основании с повышенной влажностью (например, в подвальных или цокольных этажах) рекомендуется выполнить гидроизоляцию для предотвращения проникновения влаги в стяжку. Контроль уровня стяжки по маякам должен осуществляться на всех этапах укладки, чтобы избежать перепадов высоты и обеспечить ровность поверхности

Если стяжка укладывается на большую площадь, следует предусмотреть усадочные швы, которые предотвращают образование трещин при температурных и влажностных колебаниях.

Защита от сквозняков: В процессе высыхания полусухой стяжки важно защищать помещение от сквозняков, чтобы предотвратить неравномерное высыхание и появление дефектов на поверхности.

Заключение

Полусухая стяжка пола — это эффективный и надёжный метод создания прочного и ровного основания для различных видов напольных покрытий. Её преимущества, такие как быстрое высыхание, высокая прочность и минимальная усадка, делают этот метод востребованным в современных строительных проектах. Соблюдение технологии укладки и учет всех особенностей материала позволят вам добиться долговечного и качественного результата, который прослужит многие годы.

Этот метод подходит для применения в жилых, коммерческих и промышленных помещениях, обеспечивая комфортные условия для дальнейшей эксплуатации. Если вы планируете ремонт или строительство, полусухая стяжка пола станет отличным выбором для создания надёжной основы вашего интерьера.