Холоднокатаный листовой прокат — это разновидность стального проката, изготовленного методом холодной прокатки, при которой металл подвергается прокатке при температуре ниже температуры его рекристаллизации. Этот процесс позволяет получить стальные листы с высокой точностью размеров, гладкой поверхностью и улучшенными механическими свойствами. Холоднокатаный прокат широко используется в строительстве, машиностроении, автомобильной промышленности и других отраслях. Рассмотрим особенности, преимущества и области применения холоднокатаного листового проката.

Что такое холоднокатаный листовой прокат?

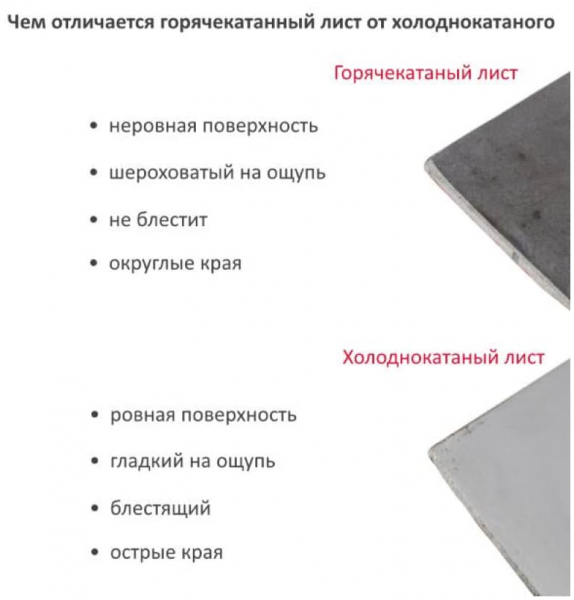

Холоднокатаный лист представляет собой стальной лист, изготовленный методом холодной прокатки, когда прокатка осуществляется при температуре ниже температуры рекристаллизации стали. Это позволяет получать более точные размеры и улучшенные физические и механические характеристики, такие как повышенная прочность, жесткость и устойчивость к коррозии.

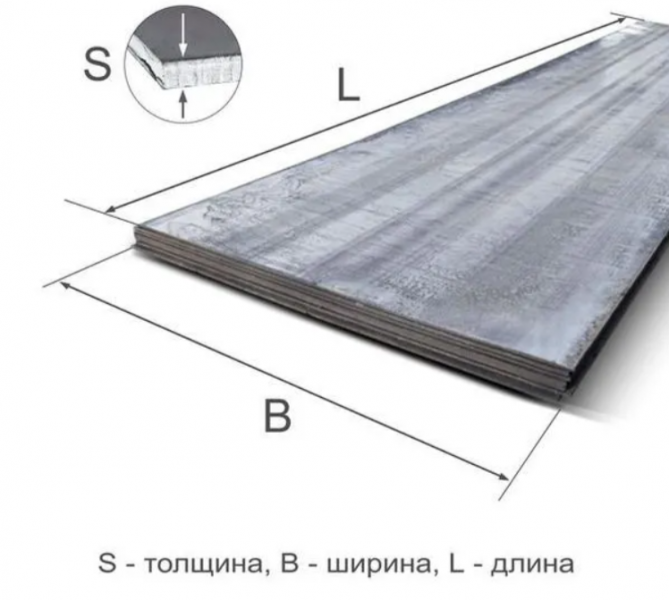

Лист холоднокатаный бывает различных размеров и толщин, в зависимости от требований конкретного проекта.

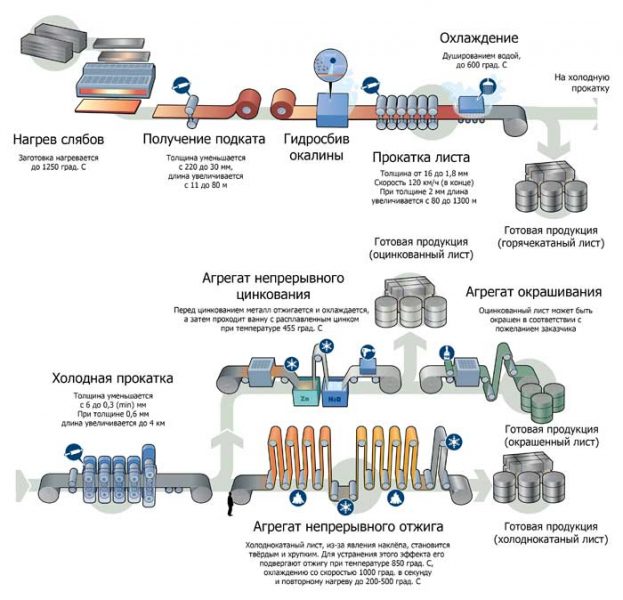

Процесс холодной прокатки начинается с подготовки горячекатаного проката, который подвергается химической обработке (травлению) для удаления окалины. Затем прокат охлаждается до комнатной температуры и пропускается через серию прокатных станов, что позволяет получить тонкие и ровные стальные листы. В зависимости от требований заказчика, холоднокатаный прокат может дополнительно подвергаться отжигу и другим видам термической обработки для улучшения его свойств.

Преимущества холоднокатаного листового проката

Холоднокатаный листовой прокат имеет ряд преимуществ по сравнению с другими видами металлического проката:

- Высокая точность размеров: Благодаря процессу холодной прокатки, стальные листы имеют минимальные допуски по толщине и ширине, что делает их идеальными для применения в высокоточных конструкциях и деталях.

- Гладкая и ровная поверхность: Холоднокатаный прокат отличается гладкостью и ровностью поверхности, что важно для декоративных и эстетических применений, а также для изделий, требующих минимальной обработки перед нанесением покрытий.

- Улучшенные механические свойства: Холодная прокатка увеличивает плотность стали, что повышает её прочность, жесткость и устойчивость к деформации. Это делает холоднокатаный листовой прокат подходящим для конструкционных элементов, подвергающихся высоким нагрузкам.

- Минимальная усадка: В отличие от горячекатаного проката, холоднокатаный имеет минимальную усадку, что позволяет использовать его в точных механических и инженерных конструкциях.

- Универсальность применения: Благодаря своим характеристикам, холоднокатаный листовой прокат используется в самых разных отраслях промышленности, от строительства и машиностроения до производства бытовой техники и автомобильной промышленности.

Технология производства холоднокатаного листового проката

Процесс производства холоднокатаного листового проката включает несколько ключевых этапов:

- Подготовка горячекатаного проката: Производственный процесс начинается с получения горячекатаного проката, который подвергается травлению для удаления окалины. Это обеспечивает чистую и гладкую поверхность, готовую к дальнейшей прокатке.

- Прокатка на холодном стане: Горячекатаный прокат охлаждается до комнатной температуры и проходит через серию прокатных станов, где толщина листа уменьшается до заданного размера. Процесс холодной прокатки обеспечивает высокую точность размеров и гладкость поверхности.

- Отжиг: В зависимости от требований к конечным характеристикам материала, холоднокатаный листовой прокат может подвергаться отжигу. Этот процесс нагрева и медленного охлаждения позволяет снять внутренние напряжения в металле, улучшить пластичность и механические свойства.

- Финишная обработка: После прокатки и термической обработки листы могут подвергаться дополнительной финишной обработке, такой как правка, обрезка, нанесение защитных покрытий или шлифовка, в зависимости от требований заказчика.

Области применения холоднокатаного листового проката

Холоднокатаный листовой прокат находит широкое применение в различных отраслях благодаря своим превосходным характеристикам:

- Автомобильная промышленность: Холоднокатаные стальные листы используются для производства кузовных панелей, дверей, капотов и других компонентов автомобилей, требующих высокой точности и гладкости поверхности.

- Строительство: В строительстве холоднокатаный прокат применяется для изготовления различных металлических конструкций, фасадных панелей, кровельных систем, а также в качестве армирующих элементов в железобетонных конструкциях.

- Производство бытовой техники: Холоднокатаный листовой прокат широко используется для изготовления корпусов и деталей бытовой техники, таких как стиральные машины, холодильники, микроволновые печи и другая бытовая электроника.

- Машиностроение: В машиностроении холоднокатаный прокат применяется для производства деталей машин и механизмов, требующих высокой точности размеров и хороших механических свойств.

- Электротехническая промышленность: Холоднокатаный листовой прокат используется для производства корпусов электротехнического оборудования, распределительных щитов и других компонентов.

- Производство мебели и декоративных изделий: Благодаря своей гладкой поверхности и возможности легкой обработки, холоднокатаный листовой прокат используется для производства мебели, декоративных панелей и элементов интерьера.

Особенности и рекомендации по выбору холоднокатаных листов

При выборе холоднокатаных листов важно учитывать следующие особенности и рекомендации:

- Толщина и размеры: В зависимости от требований проекта важно правильно выбрать толщину и размеры листов. Холоднокатаные листы выпускаются в широком диапазоне толщин, обычно от 0,4 до 3 мм, но возможны и другие размеры по индивидуальному заказу.

- Качество поверхности: В зависимости от предполагаемого использования важно учитывать качество поверхности листов. Для видимых частей продукции требуется идеально гладкая поверхность без дефектов, в то время как для конструкционных элементов допускается наличие незначительных неровностей.

- Механические свойства: Выбор холоднокатаных листов также зависит от их механических свойств, таких как прочность, жесткость, пластичность и устойчивость к коррозии. Важно учитывать эти параметры в зависимости от условий эксплуатации и требований к изделию.

- Покрытия и обработка: Для увеличения срока службы холоднокатаных листов и защиты от коррозии могут применяться различные защитные покрытия, такие как оцинковка, окраска или полимерные покрытия. Выбор покрытия зависит от условий эксплуатации и требований к эстетическому виду изделия.

Заключение

Холоднокатаный листовой прокат — это высококачественный материал, который используется во многих отраслях благодаря своим уникальным характеристикам, таким как высокая точность размеров, гладкость поверхности и улучшенные механические свойства. Этот материал идеально подходит для применения в конструкциях, где требуется высокая прочность, жесткость и устойчивость к деформации, а также в декоративных и эстетических изделиях. Правильный выбор холоднокатаного листового проката и соблюдение технологии его применения обеспечат долговечность и надежность конечного продукта.