- Потолок из гипсокартона с подсветкой – хорошее решение для спальни

- Прежде чем приступить к работе

- Материалы для каркаса

- Делаем каркас потолка для спальни своими силами

- Второй этап – монтаж гипсокартона

- Финишная отделка требует терпения и сноровки

- Встраиваем освещение и подсветку

- Что надо знать о комнате, в которой спишь

Гипс – природный минерал с хорошими антиаллергенными свойствами. Гипсокартон почти полностью состоит из гипса. К тому же он не горюч, препятствует распространению звуковых волн, пропускает через себя воздух и пар, создавая в вашей спальне целебный и комфортный микроклимат. Поэтому стены и потолок из гипсокартона с подсветкой в спальне будут самым правильным выбором при отделке вашей квартиры или дома.

Потолок из гипсокартона с подсветкой – хорошее решение для спальни

Немалое значение в выборе дизайна для спальни имеет расположение источников света. Чтобы отдых был полноценным, освещение должно быть приглушенным и не раздражающим. Потолок с подсветкой из гипсокартона как нельзя лучше отвечает этому требованию. Применение неоновых ламп в сочетании с рассеянным светом точечных светильников создаст в комнате интимную атмосферу и позволит вообще отказаться от центрального источника света.

Конструкции из ГКЛ часто делают в два или три уровня, если позволяет с высота старого потолка. Так что монтаж скрытого освещения в перепады с одного уровня на другой не составит особого труда. Часто выделенная зона на потолке продолжается на стенах в виде колонн либо ниши для кровати. Такой потолок в спальне из гипсокартона с подсветкой не только функционален, но и смотрится очень эффектно.

Площадь, форма и высота старого потолка играют решающее значение при выборе стиля и количества уровней потолка нового. Чем больше высота спальни, тем больше фантазии и изобретательности можно применить. А самое интересное, что работать с гипсокартоном можно, не привлекая сторонние организации или рабочих-мастеров. Обладая определенными навыками в обращении с электроинструментом и в отделочных работах, создать шедевр из вашей спальни вполне реально собственными силами.

Прежде чем приступить к работе

О том, как сделать потолок из гипсокартона с подсветкой, написано немало статей и снято немало видеороликов. Всех их объединяет одно – ГКЛ наряду с невысокой стоимостью обладает массой дополнительных преимуществ для использования в жилых помещения. Есть у этого материала и недостатки. Один – и самый серьезный среди них – малая влагостойкость. Если вас зальют соседи сверху – потолок придется менять, хотя трудно представить, что этот частный вариант вселенского потопа случиться именно в спальне.

Гипсокартонный потолок с подсветкой может принять какие угодно формы и цвета, и в этом его основное преимущество. Жесткий каркас, сделанный по правилам, обеспечит беспроблемное существование этого элемента интерьера на десятилетия.

К сведению: гипсовые плиты обладают определенным весом, поэтому для создания металлического каркаса желательно приобретать продукцию известных производителей в этой области. Использование некачественных профилей и фурнитуры обязательно приведет к появлению трещин на потолке и прочих дефектов.

Монтаж потолка из гипсокартона с подсветкой не стоит начинать, пока не будут выполнены следующие шаги:

- Для начала нужно сделать эскиз будущего потолка или выбрать из сотен фотографий в интернете тот, вид которого наиболее соответствует вашим представлениям о красоте. Не стоит забывать и о сочетании в интерьерами разных цветов.

- Прикинуть реальное количество уровней. Каждый такой уровень «съедает» от 6 см до 15 см высоты комнаты.

- Схема потолка из гипсокартона с подсветкой должна содержать реальные размеры, тогда есть возможность высчитать нужное количество профилей и листов гипса. Брать нужно с небольшим, процентов 15-20, запасом. Если нет опыта подобных работ, всегда существует возможность появления перерасхода материалов.

- Стандартные подвесы ограничены по длине, поэтому они применяются лишь для сборки первого, самого высокого слоя. Второй и последующие уровни создаются из отрезков потолочного профиля (ПП) и направляющего профиля (ПНП). Это те самые 20%, указанные выше. Особенно это справедливо для изогнутых линий в дизайне.

- Для крепления прямых подвесов к потолку обычно покупают анкер-клинья. Они фиксируют достаточно жестко, но и стоят немало. Их применение полностью оправдано, когда старый потолок сложен из заводских плит перекрытия с воздушными каналами. Когда перекрытие состоит из монолитного железобетона, есть возможность немного сэкономить, применив вместо анкеров обычные дюбель-гвозди, как для стены. Но этот способ абсолютно неприемлем для громоздких многоуровневых конструкций.

- Если решено использовать для подсветки светодиодную ленту, надо помнить, что блок питания рассчитан примерно на 5 м длины. Если реальная длина будет больше, стоит приобрести 2 блока.

- Кроме материалов (более подробно о них будет сказано ниже) понадобятся инструменты: лазерный и пузырьковый уровни, правило алюминиевое 2,5 – 3 м, малярный шнур-отбивка, ножницы по металлу, рулетка, молоток, нож для резки гипсокартона, маркер либо карандаш, перфоратор и свёрла по бетону, шуруповерт, дрель с насадкой-миксером, шпатели разной ширины, кисть и валик малярные. Большинство этих инструментов присутствуют в доме человека, привыкшего всё делать своими руками.

Если решимость сделать потолок из гипсокартона в спальне с подсветкой без помощи профессионалов вас не оставила, переходим к конкретным действиям.

Для небольших по высоте и площади помещений вполне подойдет потолок в один уровень. Выбор его окончательной отделки довольно разнообразен, начиная от покраски и заканчивая наклейкой фотообоев. В этом варианте можно использовать и подсветку, заложив светодиодную ленту за багет. Последний, естественно, наклеивается на стены по всему периметру либо в определенном месте, чуть ниже уровня готового потолка.

Когда пространства над головой предостаточно, есть смысл сделать двухуровневый потолок из гипсокартона, с подсветкой между уровнями. Это немного трудно для непрофессионала, но не настолько, чтобы отказаться от попытки создать маленькое чудо в своей спальне. Линии такого потолка могут быть любыми. Часто второй уровень представляет собой прямоугольник, идущий параллельно стенам.

Иногда вместо прямых линий используют изогнутые, такие варианты смотрятся довольно необычно и привлекательно. На фото ниже представлен такой тип потолка. Его изготовление стоит изучить более подробно.

Изготовить короб из гипсокартона на потолке с подсветкой можно несколькими способами, здесь будет рассмотрен самый доступный для понимания.

Материалы для каркаса

Для начала стоит сделать чертёж, указать все размеры и радиусы. Потом эту схему желательно перенести на старый потолок. Для подобной конструкции понадобятся следующие материалы:

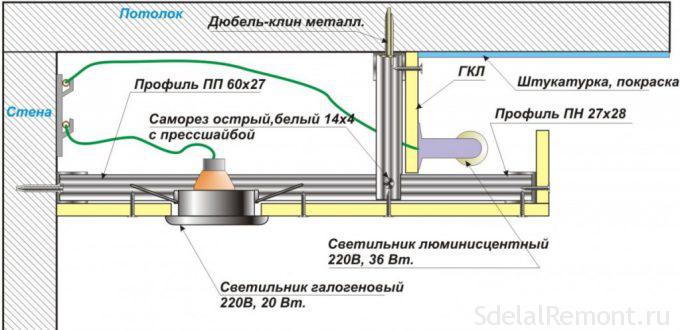

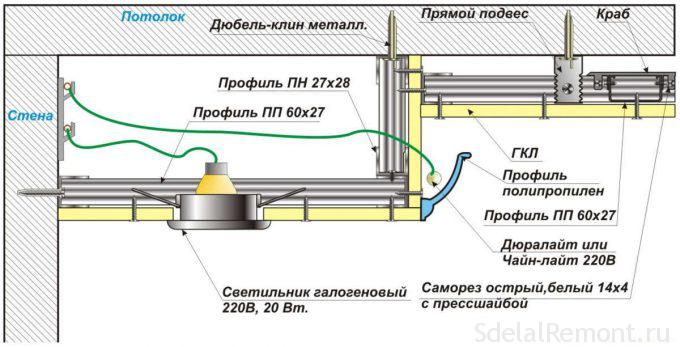

- Потолочный направляющий профиль (ПНП) 27х28 мм. Выпускается из оцинкованной стали, 3-х и 4-х метровыми отрезками. Если изделие выпущено солидной фирмой, в нём присутствуют отверстия под дюбель-гвозди для крепления к стене.

- Потолочный профиль (ПП). Имеет ребра жесткости, размеры 60х27 мм. Производится разными фирмами, покупать дешевле или дороже – выбирает каждый для себя.

- Прямой подвес обычно востребован при сборке первого, самого высокого слоя будущего потолка. Расстояние между первым и вторым слоем должно быть не менее 15 см, чтобы была возможность менять сгоревшие элементы подсветки в нише.

- Дюбель-гвоздь используют для крепления направляющего профиля к стенам. Обычно для обеспечения нормальной жесткости конструкции хватает размера 6х40 мм. Окончательный выбор зависит от диаметра отверстий, просверленных в ПНП.

- Анкер-клин – наиболее подходящий крепеж для прямых подвесов. Об этом подробно написано выше.

- Потолки из гипсокартона с подсветкой нуждаются в шумоизоляции. Особенно актуально это для спальни. Частично эту проблему можно решить, купив уплотнительную (демпферную) ленту. Она редко используется «профессионалами» по гипсокартону, но выполняет несколько немаловажных для комфорта и качества функций. Среди них нивелирование неровностей стены и гашение вибраций и звуковых волн, передающихся сквозь стены. Лента имеет клейкий слой, что облегчает её монтаж на обратную сторону профилей и прямых подвесов.

- Для создания жесткого каркаса первого уровня используют одноуровневые соединители (крабы). Они соединяют продольные и поперечные потолочные профили между собой. Стоит знать, что большинство мастеров игнорирует крабы и стыкует профили друг с другом саморезами.

- Шурупы, которыми профили скрепляют между собой в монолитную обрешетку, могут быть разными. Одни используют мелкие черные саморезы-«семечки», другие – короткие ПШ с острым концом. Не стоит лишь брать ПШ со сверлом по металлу. Их будет трудно ввернуть в мягкий профиль.

Делаем каркас потолка для спальни своими силами

Пришла пора узнать, как сделать короб из гипсокартона на потолке с подсветкой. Для потолка, изображенного на фото выше, применимы два варианта монтажа. Первый заключается в том, что вначале собирается каркас первого уровня по всему периметру, а затем к нему крепятся элементы второго слоя. Второй предусматривает сначала сборку изогнутых линий второго уровня, а затем уже армируется оставшееся пространство. Каким методом воспользоваться – выбирать вам, свои подводные камни есть у обоих способов. Единственное условие – сделать предварительный чертеж каждого из уровней.

Рассмотрим подробнее первый, он проще для понимания. Сделать сплошной каркас из металлопрофиля для человека, привыкшего работать руками, вполне по силам:

- Рисуем на стенах линию горизонта первого уровня. Ставим метки с помощью лазера, на 6-8 см ниже старого потолка. Соединяем их, отбив малярным шнуром.

- Монтируем направляющие профили. Для этого приставляем профиль к линии, делаем отметки отверстий для крепления. Сверлим по меткам перфоратором и дюбель-гвоздями прикручиваем ПНП к стенам. Забивать дюбель-гвоздь в стену не рекомендуется. Не забываем предварительно оклеить обратную сторону профиля демпферной лентой (если вы всё же решили её приобрести).

- Расчерчиваем потолок на полосы шириной 40 см – по этим линиям будут крепиться прямые подвесы. Расстояние между подвесами – 40 – 50 см, отмечается черточками на линиях. Крепятся они с помощью анкер-клиньев.

- Прикрепляем к прямым подвесам потолочный профиль саморезами по металлу. Один край профиля при этом вставляется в ПНП на стене и фиксируется. Горизонтальность конструкции тщательно контролируем лазерным уровнем либо алюминиевым правилом.

- Нарезаем несколько отрезков длиной 33 см из потолочного профиля. Эти перемычки закрепляются крабами поперечно в местах стыков листов гипсокартона. Крабы фиксируются саморезами. Стоит помнить, что ГКЛ обычно монтируются вразбежку, это предотвращает появление трещин на потолке.

В итоге конструкция должна выглядеть, как на фото ниже.

Если вы решили сделать шумоизоляцию вашей спальни, самое время этим заняться. Когда завершится сборка каркаса второго уровня, доступ к потолку будет затруднен.

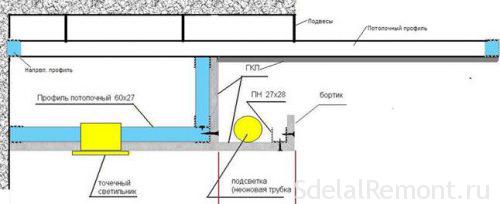

Сделать прямой короб из гипсокартона с подсветкой для второго уровня будет довольно легко, если ознакомиться с приведенной ниже схемой.

На профилях первого слоя делаем отметку по ширине будущего короба. Крепим саморезами направляющий профиль. В него вертикально вниз вставляем отрезки ПП, равные высоте перепада между уровнями минус 27 мм. Снизу вставляем ещё один ПНП, чтобы получилась рамка. К этому профилю снизу крепим ещё один, разворачивая его внутренней стороной к стене. На стенах с помощью лазерного уровня делаем отметку и прикрепляем направляющий профиль так, как это было описано выше для первого слоя каркаса. Соединяем нижние ПНП отрезками потолочного профиля, закрепляем саморезами. Прямые участки каркаса готовы.

Собрать радиусные компоненты будет чуть сложнее. Направляющий профиль в этом случае разрезается так, чтобы его можно было согнуть по линии окружности. Для облегчения сборки каркаса лучше использовать арочный профиль с помощью которого быстро создается криволинейная конструкция.

Собираются радиусные сегменты уровня в том же порядке, что и прямые участки. Так как диаметр центрального круга достаточно велик, усиливаем его поперечными вставками отрезков ПП в одну линию параллельно стене. Каркас готов.

Второй этап – монтаж гипсокартона

Перед работами с гипсокартоном делают разводку электрических проводов. Провода помещают в специальные гофрированные трубы. Делаются выводы в местах будущего расположения точечных элементов освещения.

Для обшивки потолка чаще всего применяют потолочный гипсокартон толщиной 9,5 мм. Он легче стенового и работать с ним удобнее. Для крепления к металлопрофилю используют черные саморезы с маленьким шагом витков. Но лучше использовать 12 мм. Для сведения, по технологии Кнауф делается обшивка потолка в два слоя.

Сначала обшивают каркас первого уровня. Нужно следить, чтобы между листами гипса всегда оставался компенсационный шов в 1,5 – 2 мм. Все стыки должны приходится на середину потолочного профиля. В этом случае фиксация листа будет надежной. Шурупы вкручиваются не только по краям ГКЛ, но и там, где проходит профиль, т.е. через каждые 40 см.

Затем наступает черед вертикального перехода между уровнями. Вырезать полосу из ГКЛ и прикрепить её к каркасу несложно. А на изгибах придется действовать осторожно. Придать кривизну гипсу поможет вода. С одной стороны полоски прокалываем картон кончиком ножа и смачиваем поверхность мокрой губкой. Когда гипс станет влажным, слегка его изгибаем в нужную сторону. Потом крепим полосу на место шурупами, придавая нужный радиус.

В последнюю очередь подшивается низ второго уровня каркаса потолка. На прямых участках проблем не ожидается, нужно лишь добавить 10 см по ширине для установки подсветки. Радиус закруглений также нужно увеличить. Крепежных элементов жалеть не стоит, иначе возможно появление дефектов в последующие годы.

Завершающий штрих – разметка отверстий под точечные светильники. Вырезать отверстия проще всего дрелью с насадкой-коронкой по дереву.

Финишная отделка требует терпения и сноровки

Сначала о терпении. Сразу начинать отделку потолочных панелей не стоит. Подождите день, пусть гипс «освоится» в микроклимате помещения. Да и потом придется не раз вспомнить о терпении при работе с гипсовой шпаклевкой.

Всю поверхность потолка, особенно внутреннюю часть стыков, обрабатывают проникающей акриловой грунтовкой по гипсу. Для этого используют узкую малярную кисть и валик. Дают время для высыхания слоя.

Затем приступают к шпаклевке швов и углублений от шляпок саморезов. Гипсовая смесь быстро схватывается, потому замешивать её стоит небольшими порциями, чтобы не образовались комочки. Все стыки после наложения шпаклевки армируются специальной лентой-серпянкой, вдавливая её в слой смеси. Остатки разглаживаются шпателем.

Примыкание потолка к стене тоже заделывается гипсовой смесью с применением серпянки. Впоследствии там можно наклеить багет.

После высыхания всю поверхность потолка затягивают тонким слоем – 2-3 мм – финишной шпаклевки. Здесь вам и потребуется сноровка, выполнить качественную отделку всего потолка без привычки очень тяжело. Начинать надо с труднодоступных углов и ниши для подсветки. Не забывайте обрабатывать и отверстия для светильников. Для отделки стоит поискать гипсовую смесь с добавками, предотвращающими появление плесени.

Далее потолочный короб из гипсокартона с подсветкой обрабатывают малярной сеточкой, закрепленной в специальном держателе. Некоторые используют для этой цели мелкозернистую наждачную бумагу. При этом образуется большое количество гипсовой пыли, поэтому разумные люди при этом всегда держат под рукой пылесос.

Качество обработки стоит проверить при помощи узкого луча света от фонарика, направленного к потолку под острым углом. Станут видны малейшие бугорки и впадины. Если вы готовите потолок к покраске водоэмульсионными красками, такая проверка будет кстати.

Перед окончательно отделкой потолка мастера рекомендуют обработать его грунтовкой. Есть смысл к этому совету прислушаться, но окончательное решение всё же за вами.

Завершающим штрихом будет установка бортика для ниши подсветки. По краю к гипсокартону прикручивается шурупами направляющий профиль, в местах закруглений его, естественно, разрезают для получения волнистой структуры. Нарезают лист ГКЛ на полосы шириной 6-7 см и крепят к ПНП, образуя бортик (хорошо видно на схеме вверху). Все стыки тщательно обрабатывают.

Встраиваем освещение и подсветку

Если разводка электрических проводов сделана правильно, нам остается лишь подключить к разъёмам точечные источники света и вставить их в проделанные заранее отверстия в коробе второго уровня. Затем в нише размещается светодиодная лента или неоновая трубка. В последнее время на рынке появился гибкий неон – прогресс не стоит на месте. Он дает яркое и рассеянное свечение, при котором не нужна центральная люстра. К тому же срок службы неновых трубок довольно большой.

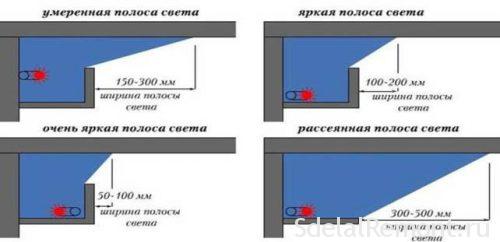

Представленная ниже схема позволит определится как с источником освещения между уровнями потолка, так и со способом его размещения в нише. Диодная лента снабжена блоком питания, который тоже легко размещается за бортиком и не бросается в глаза.

Лучше использовать монохромную светодиодную ленту. Вряд ли дискотечная многоцветная иллюминация перед сном будет способствовать нормальному отдыху. Но конечный выбор, естественно, дело сугубо индивидуальное…

Некоторые дизайнеры уверены, что насыщенный голубой цвет освещения в спальне не очень уместен. Поэтому стоит прислушаться к собственному вкусу! И напоследок несколько интересных фото потолков из гипсокартона с подсветкой в спальне, которые можно попробовать воплотить в жизнь своими силами.

И помните: «Путь в тысячу ли начинается с первого шага!» (китайская мудрость)

Что надо знать о комнате, в которой спишь

Спальня – это место, в котором человек отдыхает от суеты дня прошедшего и набирается сил перед днём грядущим. Это мягкие, успокаивающие тона расцветки стен, потолка и мебели, приглушенное и рассеянное освещение. Это минимум волновых излучений от электронных приборов, действующих на мозг отрицательно. Это хорошая звукоизоляция, ведь посторонние шумы зачастую не дают заснуть и вызывают раздражение. Это натуральные материалы. Причем не только постельное белье. Натуральным должно быть максимум предметов. Мебель, ковер на полу, и сам пол, и даже стены и потолок.

В окружении естественных материалов вы сможете отдохнуть наиболее эффективно. И не случайно в современной отделке помещений всё большее количество людей выбирает обшивку стен и потолка листами гипсокартона. ГКЛ имеют массу преимуществ перед другими отделочными материалами.