Строительная люлька, также известная как подъемная установка или подъемник, представляет собой специализированное оборудование, используемое для подъема рабочих и материалов на высоту при строительных работах. Она широко применяется для выполнения работ на фасадах зданий, ремонта или обслуживания высоких конструкций. В зависимости от конструкции и потребностей задачи, существует несколько видов строительных люлек, подробно https://lesa-vyshki.by/stroitelnye-lyulki/lyulka-zlp-630/

Устройство и принцип работы строительной люльки

Строительная люлька, или подъемник, представляет собой механизированное оборудование, используемое для поднятия рабочих и материалов на высоту при строительных, ремонтных или обслуживающих работах на фасадах зданий. Использование строительной люльки предоставляет рабочим безопасный и удобный доступ к высоким точкам здания. Принцип работы строительной люльки зависит от её типа и предназначения.

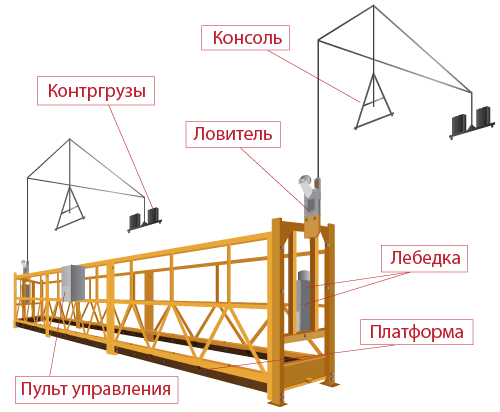

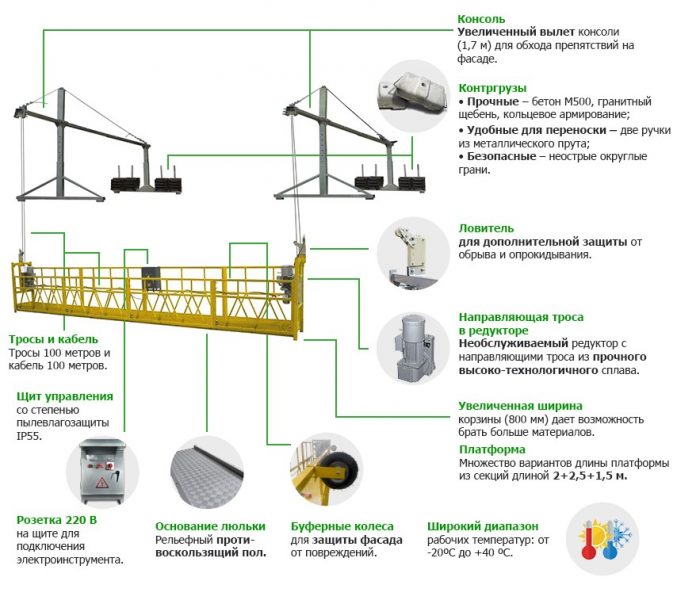

Хотя конкретные детали могут различаться в зависимости от модели и типа подъемника, общие элементы включают:

- Мачтовый столб. Основная вертикальная конструкция, к которой прикреплена рабочая платформа. Мачтовый столб служит основным элементом поддержки и направляющим для движения платформы вверх и вниз.

- Рабочая платформа. Поверхность, на которой стоят и работают рабочие. Рабочая платформа обычно оборудована ограждениями и местами крепления для безопасности операторов.

- Приводной механизм. Механизм, отвечающий за движение платформы вверх и вниз. Это может быть гидравлическая система, электрический привод или комбинация обоих.

- Управление. Пульт управления, на котором расположены кнопки и рычаги для управления движением и положением платформы. Управление может быть расположено на самой платформе или на наземной станции.

- Системы безопасности. Включают системы предотвращения падения, аварийные тормоза, предохранители и другие устройства, обеспечивающие безопасность операторов.

- Электропитание. Если подъемник электрический, то наличие электропитания, кабелей и электрической системы управления. Системы мониторинга, включающие датчики безопасности, индикаторы уровня заряда батарей, индикаторы состояния систем и другие элементы.

Эти компоненты работают вместе, обеспечивая плавное и безопасное перемещение платформы вдоль мачтового столба. Принцип работы основан на управлении движением механизмов, поддержке и стабилизации конструкции, а также обеспечении безопасности рабочей зоны. Оператор строительной люльки управляет ею, следит за безопасностью и эффективно выполняет работы на высоте.

Установка и подготовка

Прежде чем использовать строительную люльку, необходимо правильно установить и закрепить её к зданию. Это включает в себя проверку стабильности и надежности крепления, а также убеждение в том, что место установки соответствует требованиям безопасности.

Установка и подготовка строительной люльки к работе – это важные этапы, которые требуют строгого соблюдения правил безопасности и технических требований. Ниже приведены общие шаги для установки и подготовки строительной люльки:

Выбор места установки

Выберите место установки, которое соответствует требованиям производителя и местным нормативам безопасности. Проверьте, что поверхность, к которой будет прикреплена люлька, достаточно прочна и устойчива.

Перед началом работы убедитесь, что рабочая платформа строительной люльки в хорошем состоянии. Проверьте наличие повреждений, коррозии и исправность всех элементов.

Убедитесь, что место крепления люльки к зданию (обычно фасаду) надежно и безопасно. При необходимости используйте дополнительные элементы крепления, такие как анкеры или болты.

Если предусмотрено, установите стабилизаторы для обеспечения дополнительной устойчивости. Это особенно важно при работе на неровных поверхностях. Если строительная люлька работает на электричестве, подключите её к источнику энергии. Проверьте электрические компоненты на предмет повреждений.

Проверка систем безопасности

Проверьте работоспособность всех систем безопасности, таких как аварийные тормоза, предохранители, системы защиты от падения и др. Перед началом работ тщательно протестируйте управление движением и подъемом. Убедитесь, что все механизмы работают корректно. Прежде чем поднимать люльку на высоту, осмотрите рабочую зону на предмет препятствий, опасных объектов и других возможных угроз. Подготовьте необходимые инструменты и материалы на платформе строительной люльки, чтобы избежать необходимости частого спуска за ними.

Помните, что эти шаги предоставлены в общих чертах, и реальные шаги могут различаться в зависимости от модели и производителя строительной люльки. Всегда следуйте инструкциям производителя и местным стандартам безопасности.

Управление подъемом и опусканием

Современные строительные люльки обычно оснащены механизмами для подъема и опускания платформы. Это может быть гидравлическая система, электрический привод или комбинация обоих. Оператор управляет этими механизмами, поднимая или опуская рабочую платформу в зависимости от нужд. Некоторые строительные люльки также могут иметь механизмы для перемещения платформы вдоль фасада здания или в других направлениях. Это позволяет рабочим эффективно перемещаться по рабочей зоне на высоте.

Безопасность

Операторы строительных люлек должны соблюдать строгие правила безопасности. Это включает в себя использование систем безопасности, таких как ограждения и ремни безопасности, а также соблюдение инструкций по эксплуатации.

Типы строительных люлек:

Как было упомянуто ранее, существует несколько видов строительных люлек, таких как мачтовые, подвесные, блочные, и т.д. Каждый тип имеет свои особенности и принцип работы.

Применение строительных люлек позволяет улучшить производительность и безопасность работ на высоте, что делает их неотъемлемым инструментом в современном строительстве и обслуживании зданий.

Важным аспектом использования строительных люлек является строгий контроль безопасности, включая обеспечение правильной установки, надежной фиксации к зданию и обучение рабочих правилам безопасности при использовании подъемных установок.