Any sealant is a complex composition of polymer materials, serves to seal and sealing seats product compound. They are made primarily on the basis of rubber, which allows them to be flexible. Another quite significant property sealants - a high adhesion to a wide range of materials: from wood to iron. It requires a correct choice, and this should be carefully considered types of sealants and their properties.

classification Hermetic

On sale at the moment, you will notice a huge number of varieties of sealants, each of which is designed for a particular operating environment has its own characteristics, and.

It is therefore necessary to consider the classification of the material, and then, and certain types of.

Themselves directly compositions are classified in two ways:

- Number of components.

- Depending on the substrate.

By the number of components

In turn, considering the first class, you can select one-component and two-component.

Here there is also the features. If we talk about the single-component formulations, their application (infliction) immediately possible after purchase. But with two-component more complicated.

Such compositions include two component, first the material itself is, It serves as a second activator. Wherein, the second may be a different matter, and even some conditions. Total allocated three types:

- vulcanizing under the influence of moisture, heat or catalysts viscous plasticity change in elastic rubber-like state.

- do not dry out when heated becomes fluid and viscous, soften. Upon cooling, they again changed to the original hard.

- drying sealant during operation, usually, They are elastic, Recalling rubber, a position to, but in the case of exposure to the solvent, they are transformed into a liquid state vyazkotekuschee.

The majority of these compounds are not very popular, because it is the most commonly used one-component material.

Types depending on the basics

according to the polymer, located at the heart of the composition, distinguish

- Silicone

- polyurethane

- hybrid MS–polymers

- siliconized

- thiokol

- acrylic

- bitumen

- butyl sealants.

Each type has its own specific properties, advantages and disadvantages, and it can be used only under certain conditions, which should take into account.

silicone

Silicone sealants are universal, due to their unique characteristics. They are the most popular type of sealants and cheap cost.

Among the advantages of this type:

- Primarily they have high performance over a wide temperature range. Thus it can be used at temperatures of from -30 to +60 degrees, without loss of its properties.

- The polymer forms a monolithic coating, which has good elasticity and durability.

- There is a wide choice of colors composition.

But it is worth noting a few significant drawbacks:

- Though such a sealant and creates an ideal surface, but nevertheless do not stain, as in paints is a substance, destroys the structure. In this way, in the case of dyeing, when dry paint peels off.

- Such compositions do not have a high price.

- And the main problem is the inability to apply an additional layer after drying. Since in this case, both new and old layer was delaminated and have to completely re-hold the sealing surface.

In turn, this kind of material is further divided into two types even:

- acidic.

- neutral.

Each of the sub-species also has its own characteristics.

The acid can not be used to seal the metal surfaces, as it made based on acetic acid, which in turn will corrode over time, metal. And also not recommended for surfaces made of cement.

Neutral compounds, in turn, are unique, and may be applied to any type of surface. Besides, included a large number of various additives is produced with them. for example, fungicidal additive capable of creating a hermetic coating, which prevents mold, which is important when used in rooms with high humidity.

And there was also heat-resistant sealants, which, thanks to special additives capable of withstanding temperatures up to 400 degrees.

polyurethane

Sealants of this type are a unique adhesive composition, which has many advantages, among them:

- Have high adhesion to any type of building materials, because it can be applied on any surface.

- Since the material is not exposed to temperature, and it can withstand large swings, It can be used for both external, and for interior works.

- The coating may be colored.

- The composition does not corrode, and resistant to precipitation.

The only significant disadvantage of the material is marked degradation caused by ultraviolet rays.

Most often this type of sealants used in the regeneration of the roof, ventilation, air conditioners, and working with PVC plates.

Hybrid MS-polymer sealants

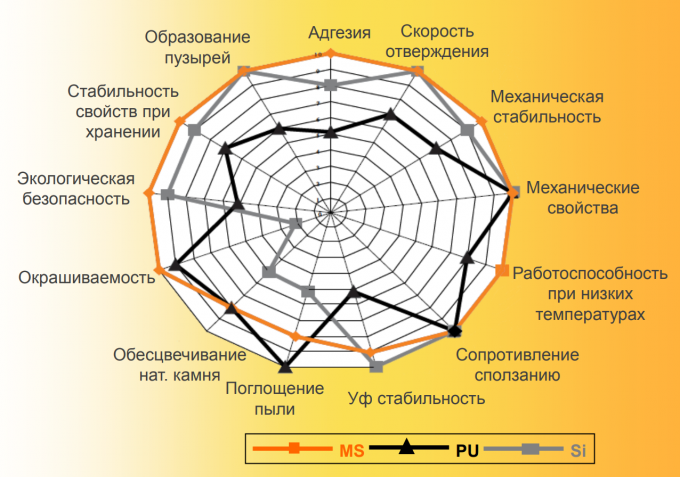

Today, this type of polymers are a part of most modern adhesive, and sealing compounds. As the latest developments in the field of elastomeric materials, Hybrid Adhesives, sealants combine the best properties of silicones and polyurethanes, thus exceeding their physical and technical characteristics.

Through this connection acquire a large list of benefits:

- Long shelf life (up to two years)

- Easy to apply.

- Odorless.

- completely harmless.

- Due to polymer hardens quickly.

- permitted coloring.

- It has high adhesion to any materials.

- Carries temperature drops to 120 degrees.

- Not subjected to corrosion and oxidation.

It has a number of advantages:

- high resistance to weathering and UV;

- preservation of high elasticity and stability properties over a wide temperature range (from -40 ° C to + 120 ° C);

- excellent adhesion to many substrates without primer;

- accelerated the time of formation of the primary film and fast curing;

- No members of silicones, isocyanates and solvents;

- neutral type curing.

hybrid sealants It serves mainly inter-panel sealing seams, due to many advantages material. It is necessary to tell and, that it is quite expensive, because its application in all areas of construction and repair is not always possible.

In industry, widely used MS-hybrid monocomponent and bicomponent polymer compositions.

this sealant, polymerizing under the influence of humidity: the higher the value of its, the faster the curing process. Factor influence on the polymerization rate and provide ambient temperature. The simultaneous increase of these parameters reduces the curing time considerably. The average polymerization rate was 3 mm per day. Bicomponent MS-hybrid polymers

MS-polymer based on polyurethanes and silicones. This allows MS-

formulations to meet the high requirements, requirements for

technological content in production and operation

lighting devices.

thiokol

The next type of sealants - Thiokol. This is one of the highest quality and durable compositions. When used in essential medium, and it is for him - an extreme situation with frequent exposure to chemical compounds, He has virtually no drawbacks, but at the same time, the mono noted a number of specific advantages:

- The high level of resistance to the constant influence of solvents, kerosene, gasoline, acids and oils.

- Resistance to weather conditions.

- Withstand extremes of temperature ranging from -50 to +130 degrees.

- The low level of capacity steam and moisture.

Talking about the application of the composition, as mentioned, it is resistant to aggressive environments, therefore used in places, which is characterized by constant exposure to the chemical elements. For the most part - it's parking, garages, refueling, station, etc..

Additional space application becomes the repair and construction of the roof, where it is used due to good adhesion to the metal, as well as low moisture permeability.

It is worth noting, what thiokol - with high quality, difficult to use.

Acrylic

acrylic sealants one of the cheapest and low in quality. They are used only for internal works mainly for painting. Although it is worth special mention, that there are some special types of acrylic sealants with decent performance level.

Among the advantages of such notes:

- Have high adhesion with porous bases, for example, wood, Concrete, plaster, etc..

- Easy to process.

- Allowed varnish or paint.

- You can prime the bases covered.

But there is quite an extensive number of shortcomings:

- Not very flexible

- afraid of water

- Can not tolerate exposure to precipitation.

- Can not withstand large temperature fluctuations.

- ELTE.

- Readily undergoes damage, and can not tolerate the mechanical stresses.

Considering all the pros and cons, this composition finds its application when installing baseboards, doors, floors, also when working with drywall. ie. the main area of application become the inner workings. Also, using the acrylic can patch small cracks in wooden furniture and brick walls.

Bituminous

bituminous compositions good at waterproofing buildings, because it has good adhesion to different types of materials, especially with concrete, bricks, metal, tree, roofing and waterproofing materials.

The only drawback is getting, bitumen fear that excessive heat, and their impact takes liquid form.

Bitumens are the most popular in the construction of houses, basements, garages etc.. Mainly used in the regeneration of the bases, installation of roofing systems, waterproofing pillars and roof repair.

Butilovyj

Such a material is a thermoplastic mass, which is created on the basis of polyisobutylene rubber.

Material has a lot of advantages, among which:

- The absence of volatile components in the composition.

- The high level of adhesion to aluminum, glass and steel.

- Is not susceptible to the effects of UV rays.

- Retains its properties when significant temperature differentials.

- Quickly sets and forms a thick, an elastic layer.

- Have a high vapor permeability

- low cost.

- Large operational period (up to 20-years).

Among the disadvantages of material:

- It has low impact strength at low temperatures.

- It has only one color (the black).

- Applicable only in the production of window systems.

Butilovye most commonly used for sealing double-glazed windows. But in addition it can also be used for additional sealing compound various kinds of designs of metal or glass. For example, can be used to strengthen the duct, gluing or thermal insulation panels for sealing containers and vessels.

conclusion

In this way, Having considered all kinds of sealants, their advantages and disadvantages, as well as the scope of the, you can choose the desired style for himself and his case personally. A further about, a company to acquire composition, refer to the separate materials of our website. And additionally we offer to view several videos, which also provided recommendations for choosing the right sealant for your needs.