- Variety of floor screeds and their features

- Tools and materials

- dry screed Technology

- The preparatory phase of the work

- marking

- Apparatus insulation of expanded clay

- Leveling heater surface

- Mounting plates GOLS from Knauf

- Positive and negative qualities of dry screed

- The cost of dry screed Knauf

- Videos on the device dry ground

In recent years, significant changes have occurred in the construction industry. There are new materials and advanced technologies. This is equally affected and execution of works on the device of floors. Beginning with 2000 of the year, the market of the CIS countries came to this technology as a dry screed floors from the German company Knauf. It is now widely used in residential apartment buildings, cottage type houses in various office establishments. The main advantage of the dry floor screed GVL is the speed of installation. It can be installed in one day, and it is immediately ready for operation in contrast to the screed, which must be 28 days for a full hardening. Also important to consider is the total absence of water during installation and a fairly low dust generation.

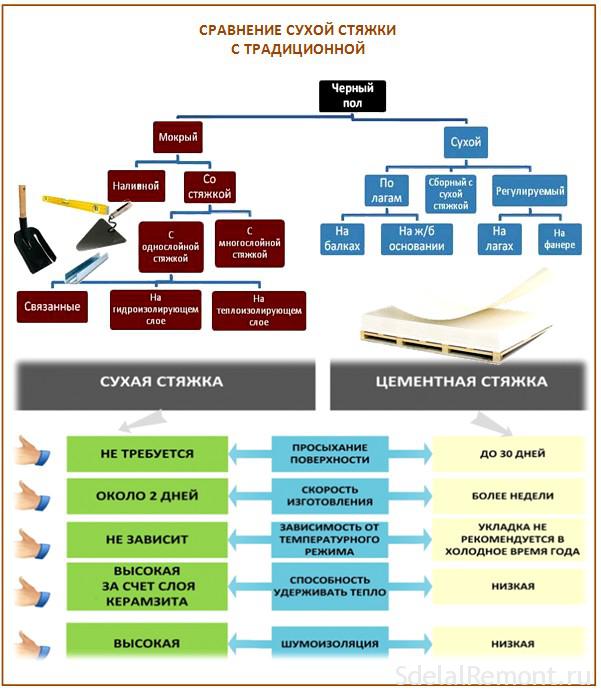

Variety of floor screeds and their features

During the construction or repair is an important element of the device durable rough coating screed, which will then lay a decorative covering such as a laminate, parquet, linoleum or ceramic floor tiles. To date, there are several types of cable ties. This is a classic cement or concrete screed, it is applied wet. There are also semi-dry screed with a minimum amount of water. There are so-called self-leveling floor, which serves for leveling the surface of the subfloor. finally, this kind of, as dry screed, which is mounted on plates of GOLS expanded clay backfill layer without using water.

Tools and materials

For the qualitative performance of works on the floor of the bulk of the device expanded clay and gypsum fiber sheets need the necessary tools:

- measuring tape and a marker;

- laser level;

- normal level of construction quality;

- drill;

- Screwdriver with nozzles;

- jigsaws;

- knife for drywall;

- square or metal ruler;

- plane for roughing edges;

- staple gun;

- guides to lighthouses from aluminum or galvanized profile;

- pravѝlo or leveling rake;

- bucket and spade;

- a vacuum cleaner;

Device for dry floor of GOLS materials will be needed, which must be pre-buy and deliver an object. Screed need:

- thick polyethylene film 80 micrometers as a vapor barrier;

- edge band width 100 mm;

- PVA glue;

- drywall screws for long 19 mm;

- filling Kompevit gravels with sizes of granules 1-4 mm;

- Sheets dry screed Knauf;

- putty Knauf

The amount of material required is calculated, based on the area and thickness of flat floors backfill. All of these calculations one can easily set their own apartments, Knowing the length and width of the room and corridor. It is worth noting, the material must be purchased with a small margin, assuming, that during the mounting will be required trimming of plates and thickness of the screed at different points may differ.

dry screed Technology

bulk floor laying Knauf technology is quite simple, but even it requires sufficient experience and skills. therefore, get the job done quickly, quality and not expensive material damage, better to turn to qualified professionals. Coordinates of such masters can always be found in the building supermarkets or on specialized sites, There you can find customer reviews.

The whole process of a dry screed can be divided into several stages:

- preparatory stage;

- marking;

- steam insulation;

- backfilling device of haydite;

- installation of gypsum screeds Knauf.

Let us consider in more detail each step separately.

The preparatory phase of the work

Before starting work on the device ties must be disassembled old existing flooring - parquet it can be, wooden floor, old tiles. If this overlap, must be sealed large dents and holes mortar or putty. After drying solution necessary to vacuum the floor surface, remove all debris, in some cases it is necessary to make the surface of the primer. By this time, all materials must be purchased and delivered to the site. You can then proceed to the vapor barrier device.

marking

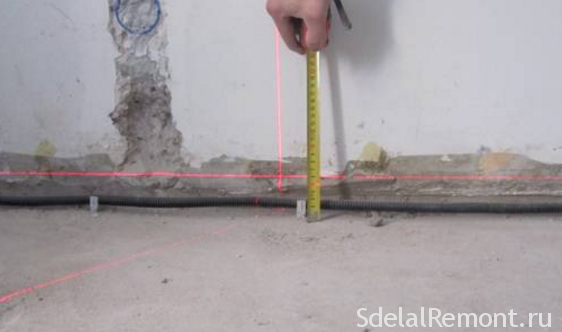

Before the device must first bulk screed fathom all rooms via laser level with the application on the walls of rooms horizontal marks. Thus it is easy to determine the difference in the levels of base in different rooms. it usually does not happen more than two or three cm. but, if you find a large difference between the elevations, then it must be taken into account when filling layer of insulation of expanded clay sand. After the measurements of all rooms can definitively determine the thickness and filling, Consequently, its amount in each room or room.

Apparatus insulation of expanded clay

After completing all preparatory operations proceed to a device vapor barrier of polyethylene film. For this purpose, the film thickness 80 micron. Lay thus, the film came to the walls on 10 cm. When using the film smaller than the area of the room, it is placed in overlapping 150 mm and glued all the joints with tape. Vapor barrier will not allow moisture to penetrate through the ceiling and damage the structure of the dry screed. All work must be performed at a temperature not lower than 10 degrees Celsius and humidity of the base 65 %. After a vapor barrier devices around the perimeter of the room to the wall mounted edge band width 100 mm. It can be mounted staple gun.

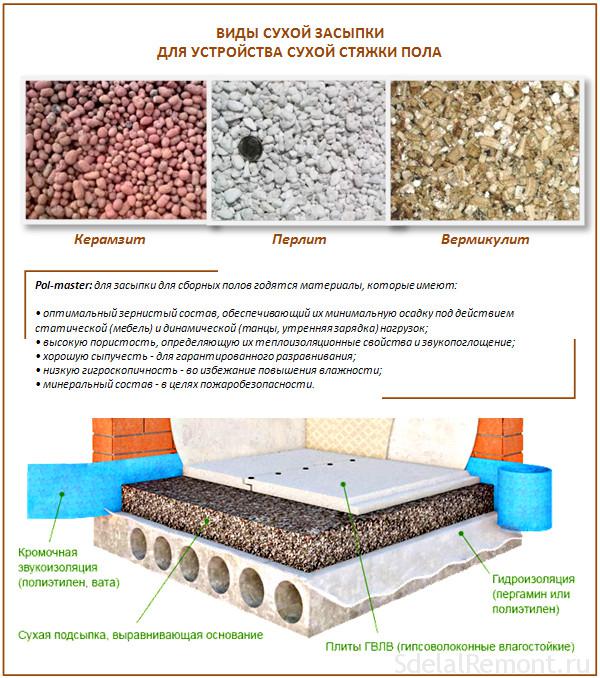

The next stage - a heater device of haydite. The best example for this is the purpose of dry filling for precast floors Kompevit, which was certified by Knauf. Until recently it was the only filling, meets all requirements. However, steel is now produced and other filling, including backfilling company Knauf. Expanded clay insulation Kompevit characterized by high quality of the granulation composition, and the absence of dust, which is a very important factor when working in residential areas. The thickness of the insulation layer may be from 20 to 100 mm. Typically, this is determined at the beginning and at this thickness and area is calculated amount of the purchased material.

After vapor barrier device and install edge band, proceed to filling the dry expanded clay for prefabricated floors, with approximately determined, how much you need to fill in a particular room. Further it is necessary to seal and smooth the surface of insulation, while ensuring a desired thickness.

Leveling heater surface

Alignment is performed using surface majachnyh two guide rails and a leveling. Slides are placed parallel to each other by the width of leveling rails. Guides are mounted on a layer of expanded clay, and the installation level is checked along the entire length using a laser leveling. In this setup the accuracy should be as high. After that, both exhibited guides, between them is filled of expanded clay backfill. With leveling lath or expanded clay channeling line the level under the level of the guide. In this case, pour the missing or removed excess concrete block, if necessary. After that, as it will be aligned between the guide strip, rearrange them on and repeat the process. As a result, should get a smooth surface insulation.

Mounting plates GOLS from Knauf

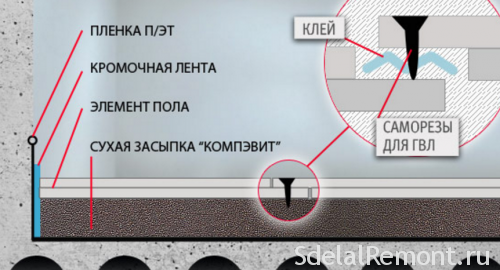

The next step - direct laying slabs dry screed. Sheet sizes GVL for dry floors are: 1500h800h12,5 mm; 1200h600h20 mm; 2500h1200h12 mm, there are also other sizes. Generally, gypsum fiber boards are produced by gluing together two gypsum boards. Mounting plates generally begin from the door opening from left to right. In the first plate, adjacent to the wall, cut jigsaw extreme docking quarter. The second plate is placed on the first after promazyvaniya PVA glue docking quarter. The third and fourth placed similarly. All parties, which are adjacent to the walls, cut off from the docking quarters. The last plate in the first row are cut on the remaining amount. Second row start with a cut-tiles, remaining from the first row. Thus achieving maximum savings, and seams of adjacent rows are shifted not less than 250 mm. After placing three rows of all the joints are fastened with screws using a screwdriver with a pitch of about 300 mm.

Self-tapping screws are screwed vertically with a small cap of about waterboarding 1 mm. If the screw went diagonally, it necessarily have to unscrew and screw the next new.

After that, all plates are stacked and secured with screws, dust and debris is removed by vacuum. Depending on the type of finishing decorative covering such, as linoleum or carpeting, all joints and strengthening of self-tapping screws are buried putty Knauf. After that, it is desirable to dry the screed to stand for about a day and you can start finishing flooring. It can be cut with a knife protruding edge of the plastic film and edge bands around the room.

Positive and negative qualities of dry screed

Dry screed Knauf has become very popular because of the obvious advantages, which include the following:

- laying screed is performed without water completely dry process, that allows you to carry it in homes, without fear of leakage on the lower floors;

- speed device bulk floor Knauf is the highest in comparison with other types of ties;

- after mounting dry screed can begin to lay a decorative floor covering, almost immediately;

- dry weight of GOLS floor screed much less similar screed;

- work on a dry floor unit of the GVL can be performed at any time of the year;

- Knauf bulk field has a high thermal insulation and sound insulation characteristics;

- construction of dry screed allows to hide a variety of utilities and floor heating elements;

- Considering that, that the laying of the bulk of sex Knauf does not require special qualifications, all work can perform any person, who knows how to use power tools.

Despite the large number of advantages, bulk field has disadvantages knauf, which can be found among customer feedback:

- dry prefabricated floors Knauf do not like humidity, and can be deformed in the event of flooding, it concerns the corridor next to the bathroom;

- this floor is not recommended to arrange in damp areas, bathroom, the toilet;

- quality gypsum fiber plate is expensive, so this tie can not be called cheap;

- if the screed settles in low areas, then she steals to constructively 100 mm height of the room.

The cost of dry screed Knauf

The cost of the bulk of sex Knauf is determined by counting the number of materials in view of their price, and added to the cost of works. Price screed thickness of about 80 mm to about 15-16 $ per square meter. Of them 9-10 $ - Cost of materials, the rest - the salary of hired workers. Now to calculate the cost of the materials on the site has built calculators, which is easy to determine the total cost of the entire screed. The approximate price of the materials:

- Gypsum fiber panels cost about 3,3-3,5 $/sq.m;

- expanded clay backfill bag 14,5 $ with the weight of the bag 24 kg;

- polyethylene film 0,2 $ for BSG. m;

- edge band 1,9 $ to roll 20 m;

- screws 1,8 $ packing.

In that case, If all works are carried out on their own, Ties value is determined by only the cost of materials.

Videos on the device dry ground