Not so long ago, in the construction industry were Knauf floors, which immediately gained immense popularity. Everything here is in a lot of merits, despite the fairly decent cost. But the price of the material significantly reduces the turnaround time, and the strength to mount spend much less.

floor Features

Bulk dry floor screed has distinctive features, consisting in, that are used in the production of natural components. The whole complex is attached to their high level of security, long service life, environmental friendliness.

Knauf floor can be used for the floor not only a child's room or bedroom, but also pantries, garages with heating. The surface in the end it turns smooth.

During the works, it is not necessary to use a wet solution, resulting in avoidance of leakage. Ready gender variant practically does not overlap on the load. It is reduced approximately 3-4 times compared to the "wet" embodiment. As for the timing of the installation work, in an area with room to 20 m2 everything can be done in about 8-10 hours.  Besides laying Knauf floor can be carried out all year round, regardless of temperature changes.

Besides laying Knauf floor can be carried out all year round, regardless of temperature changes.

Aligned floor has excellent heat insulating and sound insulating properties. Basically here helps sand from the expanded clay. If necessary, you can easily dismantle the GVL, a mixture of old replaced by new.

Virtually no such materials, who would not have the disadvantage. That's no different floors Knauf. It is true there are not critical and they can easily close your eyes. If the filling is done with a mixture of a large area, do not avoid dusty environments. So it is better to use the respirator, special glasses. floor laying Knauf should not be carried out in rooms with high levels of humidity, as the water absorption is very high.

preliminaries

The old flooring must be removed prior to all major events. It does not need to lead to the ideal flatness, and will be sufficient only to remove old waste, even possible gaps. For the term sex life will affect base. So care should be taken, to put at least a vapor barrier film. Stacking dry screed Knauf be carried out without the presence of moisture under backfilling. Otherwise, material will begin to swell, and themselves burst plate, crack. All work will have to start anew.

It is for this reason that the waterproofing has a dominant position. Before put moisture-resistant film, should all the cracks and holes are repaired, and the existing wires placed in corrugated and pressed to the floor. As a material for sealing will alabaster. He stiffens for a short time. Film sheets lie on top of each other with overlap at least 25-30 cm. For their use building tape compound. With it, the film is fixed on the walls and exposed to the beacons.

sex backfilling

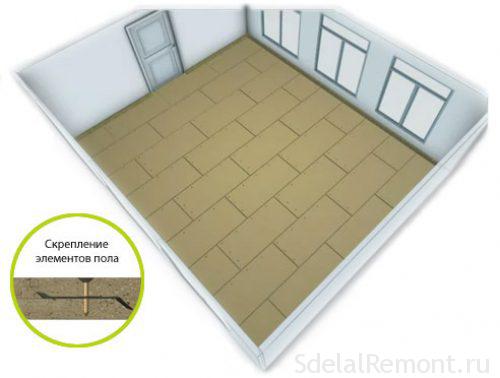

Dry screed Knauf own hands It performed very easily and quickly. Prior to the beginning of the work it is best to take a guide rail and wired with cutouts. They will be used for uniform filling. Next floor is scattered around the perimeter of the room, then you can not affect it. This applies deformation, that may arise, for example when walking.  Even if there is a need to pass on the perimeter, it is possible to make a "trail" of the sheets of gypsum fiber board. The most important thing, to the size of each fragment was, least 50*50 cm. Surface dry screed must remain unchanged. There is nothing no need to invent. This indicates, that for this material, as floors Knauf laying technology will be clear even to non-professionals in the construction industry.

Even if there is a need to pass on the perimeter, it is possible to make a "trail" of the sheets of gypsum fiber board. The most important thing, to the size of each fragment was, least 50*50 cm. Surface dry screed must remain unchanged. There is nothing no need to invent. This indicates, that for this material, as floors Knauf laying technology will be clear even to non-professionals in the construction industry.

erection work

Once dry floor screed Knauf executed their hands across the floor space, you can begin to installation. Here it is about equipping sheets GVL. There are some features, you should know before the start of work.

The first row of the plates should be positioned as far away from the inlet passageway. Subsequently have each successive sheet stacked next GOLS. The maximum gap between them should not exceed 1 mm. I.e, density should be maximized. Available joints are sealed with special glue. When produced in bulk floor laying Knauf should ensure that, to the floor surface remains unchanged, There were no injuries. If you want to make a really durable floor, then the work will be useful and self-tapping screws. dry floor construction technology provides the initial installation of the main series of plates, then it is possible to proceed to the second. It can begin with cutting boards, minimum size which is the fourth part of a single piece of. Stacking feature applies to, that with straight walls, Each sheet must fit tightly to them, and not only among themselves. The resulting gap can easily cover, using assembly foam.

Individual should be approached to the direction of sheet. It will depend on the premises and preferences. When stacking is completed dry floor knauf, joints should be aligned, sanded and plastered putty if necessary.

Job better perform together. One will be hard to keep within a certain time GVL plate at arm's length, since its weight is 17 kg. Docking to adhere to the same principle, like when laying bricks.

The choice of thickness

Technology laying dry screed Knauf provides for selection of a particular thickness. Thickness is minimally expanded clay backfill 20 mm and comes to 120 mm. Often choose two centimeters on the floor himself and laid on the plate. Such calculations are especially important when producing self-fulfilling work. Much will depend on the floor, its irregularities, who have to clean up.

Flooring unit such knauf, that with the passage of time to be ready for shrinkage. This will particularly noticeable in the case, if the laying place simultaneously in several rooms. And between them may appear elevation. In any case, the minimum thickness should be observed dry screed knauf.

required tools

When the work has to be all the necessary tools for dry screed Knauf own hands. Further material - mastic adhesive, putty, sand from the expanded clay, mixture, there must be rules (It is best made of metal), leveling rake, jigsaws, level, roulette, profile (U-shaped), drill, Cordless (using self-tapping screws), pencil, etc.. Of course, everything on this list may not be useful in the work. But anything can happen will depend on the specific situation.

Additional work

The device provides Knauf dry floor and some other types of work, which besides waterproofing fashionable and include soundproofing. The most optimum variant - the use demfernoy tape from the wall. This eliminates the moment of so-called "sound bridges", and in the presence of high temperatures, during thermal expansion - the floor is not deformed. Fixing is carried out for all constructions, arranged vertically. Thickness is enough 8-10 mm.

As a floor material can be used:

- Linoleum;

- floorboard;

- carpeting;

- Laminate;

- ceramic tile.

some deem, it is not necessary to overpay for such material, because you can find quite unique options, facing much cheaper. But with everything will be clear over time, that life is markedly different in a big way, and during operation will not occur any problems.

Tips

Tech dry floor screed Knauf does not give additional difficulties for workers. Anyone can do it without the help of professionals, that for their services require payment. There is also some nuances, you should know:

- Profiles are set away from the wall. The most important thing, so that they are parallel to each other. The distance between them is taken as the average 140-160 cm. In this case, the rule must be large in length, than the specified distance. After filling it should be razrovnena throughout the area.

- bulk floor stacking technology is not yet thoroughly known to all. For this reason, many cut off seam with the sheets, which are located near the wall. Do that in any case can not be, since from the floor in this place for a short time begins to sink, it will be very evident.

- Profiles have to be removed after filling. If they leave, it can deform used floor covering. And for the expanded clay is characterized by shrinkage, that is not true about the exhibited items. The very concrete block at the same time should be as dried, to floor deformation is minimized.

- The joints between the sheets is best to glue using PVA glue. Assembled floor in such a case will acquire higher strength, and subsequently it will be possible to produce the finish.

If the device of bulk floors Knauf executed at an appropriate level, and according to the rules, requirements from the manufacturer, it will show all its advantages in practice. He will be able to last for a long time and constantly delight.