Screed floor in a new building has its own characteristics. But first and foremost it is needed, to make the floor even for subsequent flooring. Floor alignment in new building can be done in different embodiments, who must choose each independently. It is important to acquire the necessary materials and equipment, not to be distracted during the work.

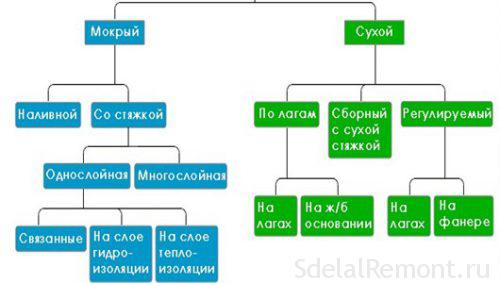

Selection of ties

When the screed, the floor is not only becoming even, but also more durable, reliable, increased heat- and sound quality. The same applies to the time, when you want to hide all possible communication, located on the floor surface. Based on these parameters, is selected and an option for the screed, selects a particular technology, which identified three main:

- adjustable floor. plywood sheets used for its manufacturing, as well as support. Recent needed, to set the height of the next floor, i.e. the distance from the base to veneer.

- Using dry fillings, on top of which are placed sheets - special plate.

- Stud specialized water mixtures. In this way, obtained Cement-sand screed or plaster.

The difference between "wet" and "dry" screeds

The most popular is the third technology floor unit in a new building. This is due solely to the fact, that all the material constantly available for purchase, technology familiar to everyone for a long time, and the cost is very acceptable. But it is increasingly possible to name a habit, not optimal for this. As for the price, then there should be added to the shipping costs of all materials, not only to the entrance, but also in the apartment, All loading and unloading operations. This is a decent adds the final amount. There may be cases, when the thickness of the floor for a full alignment becomes very large. In this case, you can not do without the expanded clay, which is shed "milk" of cement. But in the end still do fine cement, whose thickness is approximately 3-4 cm.

If desired, to minimize noise in an apartment, their spread through all the rooms, the useful option of adjustable floor. But the need to pave the layer of sound insulation, produce reinforcement by a metal mesh.

Dry screed will cost a bit more expensive. But if you look at the final result, we can immediately discard all other options. Pressure on the minimum overlap, the work is done instantly and without dirt. And moreover, such a material has a high sound insulation, heat and noise insulation properties.

screed floor in a new building which is better, it must be assumed, To meet all requirements and quality parameters. Only then will a level floor, on which you can put any floor covering completely without problems.

cost of

Several details should focus on screed cost in new. Significant costs here even at the expense of, that much effort is applied to bring the floor level to the required setting. consumables prices constantly rise up. Can stay in two embodiments - wet and dry. If you take the same thickness, for example, in 6 cm, then the "wet" ties we need per square meter 150 rubles for the average price of cement-sand mixture. But here is to add the cost of works, that are about 400 rubles.

"Dry" screed includes not only a mixture of, but also the sheets of GOLS, screws, glue, waterproofing layer. All this will cost about 550 rubles for each square area. Additional charges and labor in the area 350 rubles. Total turns, that the cost of the second option will be almost twice as large, than in the "wet" embodiment. It is true all the positive features and the ease of installation works all these things overlap. In any case, everyone is trying to find a way and the option, how to line the floor of the new building is cheaper.

preliminaries

Stop your opinion is on the dry version of floor leveling. Screed floor with their hands in a new building is done much easier, and not have to wait about two weeks, until it dries, to proceed to the next stage. After all, everyone wants to do everything as quickly as possible and quickly move into their own housing.

Technology to start work, should carry out all measures to clean up the base. If there is little dust and debris, it is useful to building cleaner, that all this will take away without problems. Existing cracks and holes should be repaired as much as possible. In some cases it will be necessary, and to extend their, that the result was more effective. For sealing the grout is most often used.

For the element "rough" floor acquired sheeting, which can be gipsovolokno, plasterboard, plywood. Everything depends on the room and its characteristics. Which is better? Sam consumer has the right to make the final choice. System efficiency has OP 135 German manufacturer Knauf. Dry precast floor is obtained without voids, while possessing excellent properties of heat and sound insulation. Application is directed to sheets GVLV, which are water-resistant.

There is a caveat here, which is, that like visually very smooth plate, but the reality is quite different. When performing cutting them releases massive amounts of dust, which also has a negative impact on work. In the alignment process should follow the floor thickness. If it will be minimal and within the 3-4 cm, it is sufficient and one layer of plates applied. But with greater thickness - it is better to take two coats. This will make the entire structure more robust and reliable.

floor laying technology

After buying an apartment in new building, We should think about, to make a quality floor, follow the base technology. Apply here experts not rational, as it would require almost twice as costly. The main thing to have at least some idea about the ongoing work and know some of the subtleties of. Then everything will turn out fine. Some do not even know about, how to make a screed floor in a new building. First of all gather in one place not only material, but also the necessary tools. If you take the "wet" version, Fill the floor in the building with his own hands will be much cheaper, though it must be assumed, that we want to get in the end. Preparations in any case carried out in exactly the same.

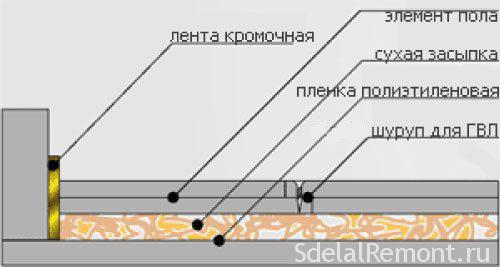

When the base is prepared, performed dry screed with their hands step by step. Subsequently proceed to a device waterproofing layer, wherein the polyethylene film is used most often. It should go on the walls 60 mm above the, than the next floor. According to the perimeter of the floor made laying tape insulation or mineral wool.

We should not forget about the guide for dry screed. They will serve as a starting point for the entire floor level. That everything was done really high quality, It is not superfluous to use a laser level. On it are exposed beacons and benchmarks for the floor height across the room, where the works.

On guides carried filling the dry mixture. It shall be applied uniformly and without gaps. Do not be amiss to lightly tamp the entire floor space. This will fill all possible voids. It is this layer will be the main floor for future. So that should make forces, to get a good result. Fraction any backfill material used should not exceed 5 mm, and in some cases much less. Some people prefer to use styrofoam plates. The truth is it depends on the flatness of the base. Laying subsequent sheet materials is carried out in the direction of the entrance. true, then the opinions of experts differ. Dry floor leveling is done with his own hands in the shortest possible time and much cheaper, if you do not attract specialists.

In some cases, to make the reliability of the whole structure, make two layers of sheets. Between them they are connected by means of screws and glue PVA. The most important thing, that in the process of installation, the bed of a dry mix remained at the initial level and will not shifted. In this situation, it is impossible for her to mark, and if there is such a need, the minimum size underlay sheets 50*50 cm.

Apparatus floating screed

Floating dry screed is performed in cases, when there are specific quality of space, which include high humidity, temperature changes, the organization of "warm" floor, etc.. It also has its own technology, which includes some very important steps:

- Besides the usual removal of dirt at the initial stage it is wise to spend washing floors, to identify all the existing defects, treat with antiseptics (reduce the likelihood of mold and mildew).

- When the device for floating screed insulation, on the perimeter of the room held two lines horizontally.

The second would be needed for DSP, and the first - for the location of the insulation layer. Alignment in this case is more qualitative.

The second would be needed for DSP, and the first - for the location of the insulation layer. Alignment in this case is more qualitative. - Depending on the room, where the works, and material selected for waterproofing. The cheapest option - a polyethylene film. Membrane waterproofing fit in bathrooms, as well as in the kitchen. Instead, you can take and bitumen mastic, that lubricates the base of the wall and floor.

- Marked line on the upper horizontal tape attached damper. Its cost is not high and you can always find it in stores.

- Increase the sound insulation slabs of expanded polystyrene, which are stacked on the floor. Instead, it is possible to perform filling of the dry mixture in the form of expanded clay.

- Important point reinforcement. The material can take ready-made grid, made of plastic or metal.

Alternatively acts rebars. To reliability was higher, used reinforcement layer should be arranged in the central part of our "pie". As in this case the abutment used wooden blocks required size. If the room is large in size, it should be expose beacons, Since conventional horizontal lines will not be enough. They are cemented on the basis of, but the main thing is not to damage the layers of all placed. All beacons must be placed on the area in regular intervals and at the same level.

Alternatively acts rebars. To reliability was higher, used reinforcement layer should be arranged in the central part of our "pie". As in this case the abutment used wooden blocks required size. If the room is large in size, it should be expose beacons, Since conventional horizontal lines will not be enough. They are cemented on the basis of, but the main thing is not to damage the layers of all placed. All beacons must be placed on the area in regular intervals and at the same level.

If you use a "wet" screed, after filling it must be covered with plastic film. Drying will take place at the same time evenly over the entire area and the most important thing is uniformly. But this option is only ties take time.

professional advice

dry screed with his hands can be performed at any temperature modes. But if we are talking about floating floors, it is best to choose a room temperature, and even the humidity is the minimum. there is a nuance, concerning floating floors, that during installation you can not apply different glue, screws, nails and other materials. Sami prefabricated panel thus must for some time to lie in the other room, having similar temperature parameters. Skirting for floating floor mounted only after about 6 hours after the main installation work on the establishment of the base. Dry screed in this case is much simpler, as the specific requirements for itself and does not produce as fast as possible without the involvement of external forces.