Mounting dry screed is carried in the case, when as soon as there is a need not only to make a smooth coating floor material, but also give it an excellent heat and sound insulation qualities. The popularity of this option floor devices is increasing every day due to the many positive features. All work on the floor of a dry screed can be performed independently. The most important thing to know the technology itself and some of the subtleties, to be faced. In this case the material itself for dry screed can be quite different. Everything will depend on your preferences and the specifications of the future sex.

The essence of the work

Work to dry screed floor is the process, which includes the preparatory stage, wherein the base is an alignment directly under the next floor, filling the dry mixture, styling sheets. This so-called prefab floor leveling process.

Technology It differs significantly from the "wet" embodiment. It can be applied not only in new buildings, but even in old apartments at the time of repair. It's not important temperature readings, and most importantly the desire to work and perform all the steps in sequence.

Regarding the number of sheets used on top of backfill, then there will depend on the requirements for the future floor, its use, and a layer of the dry mixture, which will vary depending on the need for careful alignment of the base. As a basis for the future there may be half floor slab, wood floors, logs, and more. It is certainly possible to consider alternatives, the most important thing, to the installation of dry screed Knauf had more positive qualities, than disadvantages.

Advantages and disadvantages

Dry screed Knauf has pros and cons, which show her hand. Due to these features and there is a choice of a particular variant of a floor unit in a room. Among the advantages are the following moments:

- Less than the cost of time and effort in the process of installation works. In addition, it is not necessary to wait until the ground is dry, and is immediately ready for decking flooring, which you can choose any brand material.

- Best sound, heat, soundproof floor quality.

- Ability to hide all the communication, electrical wires in a completely any room. It is enough to put them in a special corrugations or pipes made of polymer materials.

- Doing the work yourself without expert.

- Laying knauf floor elements performed under any temperature conditions, in any season. the main thing, to the humidity level was appropriate. The material itself is very picky about this indicator.

Despite, what, in fact, subfloor becomes very easy, ready version of the floor is able to withstand not only the constant adventures, but bulky furniture, household appliances. The main thing to choose the right flooring. Mounting dry screed floor has an extensive field of application, allowing it to replace all of the usual "sand-cement" options, is not capable of withstanding subzero temperatures.

There are many advantages of such material, but it is worth paying attention to the shortcomings of the dry screed floor KNAUF. The most basic of them - it does not tolerate high humidity. If water under the floor, it does not just have to be dried for a long time, but most likely, and perestilat, carrying out dismantling work floor covering plates and. Good, that the cost then go minimal. But even this can be avoided, if you observe the works technology, as well as the sequence of actions. Many disadvantages arise due to the inexperience of the master, haste and poor utilization of the material under dry floor. Dry screed has drawbacks to a greater extent due to the fact, which increases the level of the floor. This is particularly evident in areas with a small ceiling height.

cost of

Some before the start of work want to get the answer to, how much dry screed. All will depend on the material used, which is used to dry the screed thickness of the backfill.

The best purchase option - the purchase of prefabricated kits. This includes all necessary and high quality. But in order to save money better yourself go to the shop, and buy on their own.

Upon receipt of information on, how much dry screed floor KNAUF, it is important to consider not only the material, but also accessories, which includes film, screws, Clay and t.d. Stove GVL will cost about 250-300 rubles per m2, polyethylene film - 20-35 rubles, packaging screws - 140-160 rubles. Wholesale prices will be much lower, than retail. This should be taken into account to make purchases and parties, everything, it will take to repair.

Application area

Using dry screed aimed at, to implement floor leveling prior to installation work, as well as the need to make the strengthening of the wooden floor. The same applies to rooms, if there are existing pipes of different systems, electric wires. Since all kinds of works are carried out as soon as possible, the perfect choice for such buildings, or if you want to quickly move into a purchased apartment. This applies to the temperature conditions outside.

With regard to specific premises, it is not recommended for bathrooms and kitchens, when there is a high probability of flooding or leakage of water. This has a negative effect on the material itself.

Materials used

Prior to the installation of dry floor should prepare the required materials. This includes all of the thermal insulation and waterproofing, directly filling in dry form,  which options appear on the market, fasteners, glue, sheeting. It was the last and special attention.

which options appear on the market, fasteners, glue, sheeting. It was the last and special attention.

GVL can be carried out laying on the floor, apply drywall, plywood, OSP, Sheets of asbestos and cement. First, we should start from the technical parameters of the material and the final requirements for the floor. In their production takes place crumbs compaction of the foundation of gypsum or other products with the pulp (paper or paperboard). To the sheet has high strength, reinforce their hydrophobic composition. The front side is ground, to the surface "rough" sex is smooth and ideal for the subsequent flooring.

Panels for floor leveling have different thicknesses, that has an impact on the overall height of the dry screed. If gypsum fiber sheets will 10-20 mm, the plywood - somewhat thinner. And variants of each of them there is plenty. With the help of gypsum fiber board is very easy to align the floor. The sheets may be standard or have the ability to resist moisture. In addition they have such properties, as fire, environmental friendliness, insulation property.

It is important to choose the right dry screed GVL. From the manufacturer will depend on the quality of the product. This primarily relates to the surface roughness. In appearance like each sheet will be the same, and have a perfect flatness of the entire plane. But when he is placed on the filling, the visible error or engages. There can influence not only the workmanship, as well as warehousing in stores.

Training

Prior to the installation of dry screed, should prepare the base. There is nothing special from the artist does not need. It should only be cleaned thoroughly "foundation" of the future and make sex possible terminations of existing cracks and holes.

Mounting knauf dry screed floor can be carried out on the soil surface. The main thing to protect the pipe passing, wiring, cable. The best option - laying in a box.

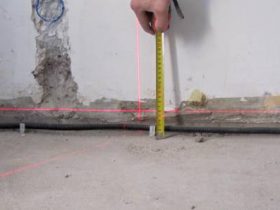

In addition, sex is determined by the horizontal, over which the installation of all components. As a tool it is best to use a laser level or gidrouroven. It is best to make a landmark on all premises, Where are the screed floor. Here help the above tools.

In order not to face the disadvantages of dry screed Knauf, it is best to use the services of professionals. They will perform a dry screed turnkey, and the customer will only have to take a job. But even then it is best to study the technology in all phases of the work, monitor the implementation.

We can not forget about a damp-proofing layer, insulation and installation beacons. Dry screed on Knauf technology provides for laying of plastic film on the base, which was prepared. Alternatively acts glassine. You can even take pieces of such material, but then you have to perform an overlap equal 150-200 mm. He must go on the walls around 50-70 mm. Subsequently, the exposed portions of the film may be cut off or hidden under the baseboard. This layer sidestep in no case be, since at the slightest occurrence of moisture, it will have a negative impact on filling, damaging it.

Gap left between the wall and the floor performed dry or filled with mineral wool insulation tape. Even when a curvature of the finished floor material, its deformation does not occur.

For horizontal alignment dry mixture, used as backfill, exhibited beacons. You can take the profiles, fixed on the basis of. Acute part they turn up, which virtually eliminates their contact with the sheets of gypsum fiber board.

erection work

When all kinds of preparations came to an end, you can begin the installation process. The first step is to take care of the choice of filling, which must necessarily be homogeneous.  The most popular option - a concrete block. true, not know all, a concrete block for dry floor screed choose. The most important thing, that the fraction was the maximum 5 mm. You can even fill the small concrete block for dry screed. If necessary, can be accomplished minimally rammer. As an alternative to expanded clay:

The most popular option - a concrete block. true, not know all, a concrete block for dry floor screed choose. The most important thing, that the fraction was the maximum 5 mm. You can even fill the small concrete block for dry screed. If necessary, can be accomplished minimally rammer. As an alternative to expanded clay:

- Quartz sand.

- Fine-grained slag.

- Perlite etc.

The thickness of the dry tie will depend on the uneven floor. For dry minimum thickness of the screed 20 mm.  Here it is necessary to carry and concealment of all communications, available in the room. If the layer reaches dry screed 60 mm and more, you'll need to produce a sheet material stacking two layers. Reliability is still in first place. It does dry screed maximum thickness 120 mm.

Here it is necessary to carry and concealment of all communications, available in the room. If the layer reaches dry screed 60 mm and more, you'll need to produce a sheet material stacking two layers. Reliability is still in first place. It does dry screed maximum thickness 120 mm.

LECA dry screed crumbles indoor initially at such area, to be able to put a few sheets of gypsum fiber board. Otherwise, it will be inconvenient to move, and the excess amount will hinder fastening of sheets together. Even these details will help us to answer the, how to make a dry screed floor with their hands.

Infusion of leaves

The upper part of the dry screed - sheeting. In most cases, they are selected from gipsovolokna. They have the best reliability and quality, than drywall. Besides, the latter is most often used for walls and partitions device, and not to be walked on. To a well between sheets joined, they have rebated edge.

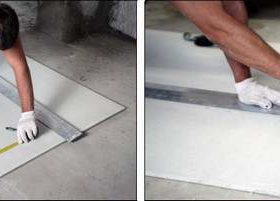

Styling sheets mostly carried out from the front part of the room. Floor Leveling GVL is quick and easy. the main thing, To keep dry screed knauf technology and stages of action. On top of the mound you can walk, to carry out the flooring sheets, but it will take to put a GVL, which is the minimum size 50*50 cm. The main sheet itself is minimal move on expanded clay under dry screed. The subsequent sheet is placed in length, and the joints between them are coated with glue, then twisted screws. Frequency screwing screws is 5 cm. Each joint has to be scrolled.

Styling sheets mostly carried out from the front part of the room. Floor Leveling GVL is quick and easy. the main thing, To keep dry screed knauf technology and stages of action. On top of the mound you can walk, to carry out the flooring sheets, but it will take to put a GVL, which is the minimum size 50*50 cm. The main sheet itself is minimal move on expanded clay under dry screed. The subsequent sheet is placed in length, and the joints between them are coated with glue, then twisted screws. Frequency screwing screws is 5 cm. Each joint has to be scrolled.

During installation, It is important to know, how to tie their own hands dry. Any mistake in the future will lead to deformation of the floor and holding the demolition work. That gypsum fiber sheets must go to Extension, Similarly,, How to produce bricks or masonry laminate device. It is important to the number of pages in length, as well as the size of the trimming.

To reduce the number of waste sheets, disposable dry expanded clay over the screed, stowed second row of the residues starts after first-line. And indeed Extension turns in the required value.

Not really get hung up on the, a concrete block better for dry floor screed. the main thing, that there was a corresponding fraction of. It is important to ensure that, that in the process of fixing the sheets and gluing them with glue in the joints, It was not a crumb infill. It is possible to sweep a paint brush. Only in this case, reliability is always the first place.

Looking at the final result and a perfectly flat floor surface, it turns out the answer to the question of, how to make a dry floor screed. After completing all the steps, desired result is obtained. From the number of sheets will depend on the thickness and dry floor screed.

Final work

When the device is configured floors GOLS, You can proceed to the final stage. Using stationery knife, cut off the protruding part of the insulator. There is also action, to be performed in order, to get an answer to that, how to make a dry floor screed. They will depend on the used floor covering.

- Apparatus dry screed knauf the kitchen is performed with an additional waterproofing layer. Here it is suitable not only film, but bitumen coating.

- Putty closes all cap screws, when the top sheet is laid linoleum GOLS, or the like filler floor.

Superfields dry screed is carried out as quickly as possible due to the technology. For everything will be spent 1-2 day. The adhesive is completely dry, and material alone otlezhalsya, enough for a single day. Similarly runs dry floor screed turnkey.

Conduct all types of installation work on the device dry and the floor can be self. At the same time made savings on attracting professionals, Yes, and you will do everything for yourself. The main thing to observe all the conditions and advice from professionals, who certainly know, how to make a dry floor screed. Should not adhere only minimal layer dry screed, but the number of layers of sheets of gypsum fiber board. Sami sheets should be fixed firmly to each other, fastened with screws, to not to have appeared to a dry floor screed disadvantages over time. Yet the positive features of a much cover the possible disadvantages of the.

Dry floor screed GVL requires minimal effort, but this gives a really smooth surface, suitable for any floor covering.