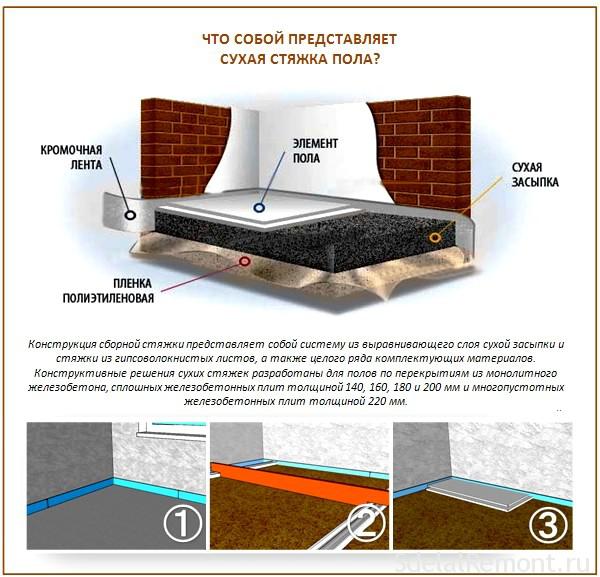

Coupler it is mandatory. That it is a base for flooring. This layer should be as straight as possible to perform, using various options. If previously widely used casting, it is now gaining popularity dry screed. This is due to a large number of positive features, and the cost of the materials is virtually identical. The most important thing is to work out all the details, If you are dry screed with their hands.

Advantages and disadvantages

When performing work on their own, it is important to clarify those points, which will be attractive while using dry screed:

- It is not necessary to apply water to the technology, which brings less dirt.

- When using a porous expanded clay serves as an additional insulation layer. The room becomes much warmer.

- Dry floor screed in the apartment allows you to reduce the pressure on the slab. It speaks to the fact, that this method is suitable even for old buildings, where there are hardwood floors.

- Excellent sound insulation properties. Noise, which can get into the apartment, It is almost completely absorbed.

- Maintenance of sanitary equipment or equipment of the heating system much easier to service, if used screed dry. There is no problem to install a floor and water.

- Expanded clay or sand is poured onto any surface, which indicates the versatility of this technology.

Here it is necessary to add also the time, that after all the work on the creation of sub-floor, possible to start laying a floor covering. Drying is not necessary to expect, but, Consequently, It reduces the time of repair in apartment.

Dry screed in the apartment has its drawbacks, which arise from the use of the material, as well as violation of the installation work. These include:

- Shrinkage of the mixture over time. This leads to the floor deflection. For this reason it is best to eliminate the dry floor screed in areas with high traffic, and also where most of the dimensions of the furniture will be used.

- cost of. dry screed technology will be more costly in terms of purchase of materials.

- The low level of water resistance. From the bottom of the floor and the floor covering sheets used are protected from moisture. But here's the external protection is almost impossible. Emergency water leak can lead to the production data sheet change, but, Consequently, additional costs. For this reason, in the bathroom make the best waterproofing layer, and sometimes arrange several layers for reliability.

Disadvantages can occur when using dry screed, if broken stacking technology. Since there is the creaking of the mixture itself over time. This occurs most often when a large layer of backfill. can be avoided, using uncalibrated keramzit.

Tools and materials

When we begin to produce all kinds of works on the device of sex, it is important to have on hand the necessary material and equipment. In addition, there will be no harm and partner, which will provide assistance at all stages of installation. Sheets may be used independently of GOLS size 120*60 cm. Laying is performed with less expenditure of energy. The materials will be needed keramzitopesok, having a diameter of about 5mm, polyethylene film, screws, if you want to mount sheets, PVA glue, edge band.

Particular attention should be paid to used tools. Measuring and cutting - a pencil and tape measure, mounting plates - with the help of the screwdriver, Cutting sheets - jigsaw or a special knife. Also in handy spatula, rule, metal profile.

It is not necessary to use a one-piece concrete block for the reason, the floor is not only prosyadet markedly over time, creak too appear exactly. The maximum thickness of the pellets - 5 mm. Otherwise you will have to redo everything.

When selecting a material for filling, then there must first determine the thickness, which will depend on the available communications, the floor, ego Rovnosti. The average thickness of 30-50 mm. From time to time may be up to 60 mm. But in the latter case, we need to also attach additional sheets as a layer. The most important thing, that the selected material has a maximum size up to 5 mm, humidity not exceeding 1%.

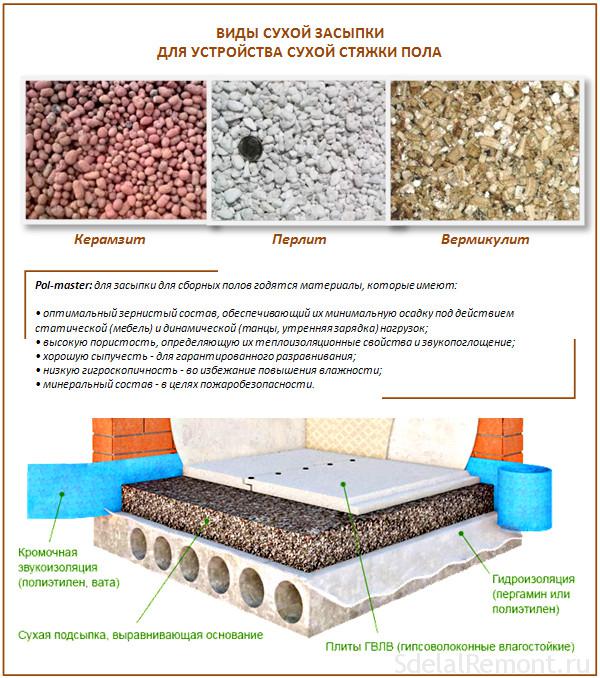

- Expanded. Are granules of clay, which have passed the firing process. Selection carry dust and sand, otherwise you'll have to listen constantly creaking floor. Dry tie their hands should be at least a layer 30-40 mm.

- perlite. To all the moisture has been removed from the material itself, produce thermal shock at a temperature of about 1 000 degrees. Used in the expanded form.

- vermiculite. it is heated, bringing the sticks are formed of silver and gold. Their appearance reminiscent of worms. Markedly reduced the load on the plate compared with the expanded clay around 2.5-4 fold.

- Kompevit. Almost no mistakes in choosing. Apparatus dry floor screed remove such material allows deformation of the floor, and sound insulation and heat insulation level significantly increase.

preliminaries

Runs dry screed with his hands in stages. For the main stage should prepare the old floor. The coating is removed, the surface is cleaned and taken out all the possible construction waste. Any visible damage to the surface to be eliminated and possible sealed. To remove all possible surface irregularities, a renovation of floors in the apartment dry screed.

When there is a pipe communication, they can be passed through a corrugated polyurethane. Tie layer in this case must be at least 20 mm. But we must be attentive to the fact, not to go through with the maximum settings. After filling level should not reach higher 120 mm.

Dry floor screed in the apartment with his hands should be at smooth walls. Many neglect this. The coating should remain close to its base, which increases the reliability of the whole structure.

Arrangement isolation is performed using glassine paper or polyethylene film. Everything will depend on the subfloor. If the asphalt is used for wooden floors, the polyethylene - for concrete. Sheets should go on the wall, overlapping in 15-20 cm. the main thing, that he was above the filling level. From cold bridges and sound will help get rid of a damper tape.

She also glued slightly above the floor, and subsequently trimmed to the required parameters, or is covered by a plinth. Technology dry floor screed in terms of waterproofing somewhat different for wooden surfaces. Here it is best to use construction paper, impregnating having gudronovuyu.

Waterproofing tape is used at the junctions of the walls, together with a special waterproofing layer on the floor surface in the bathroom and other areas with a high humidity level.

dry filling

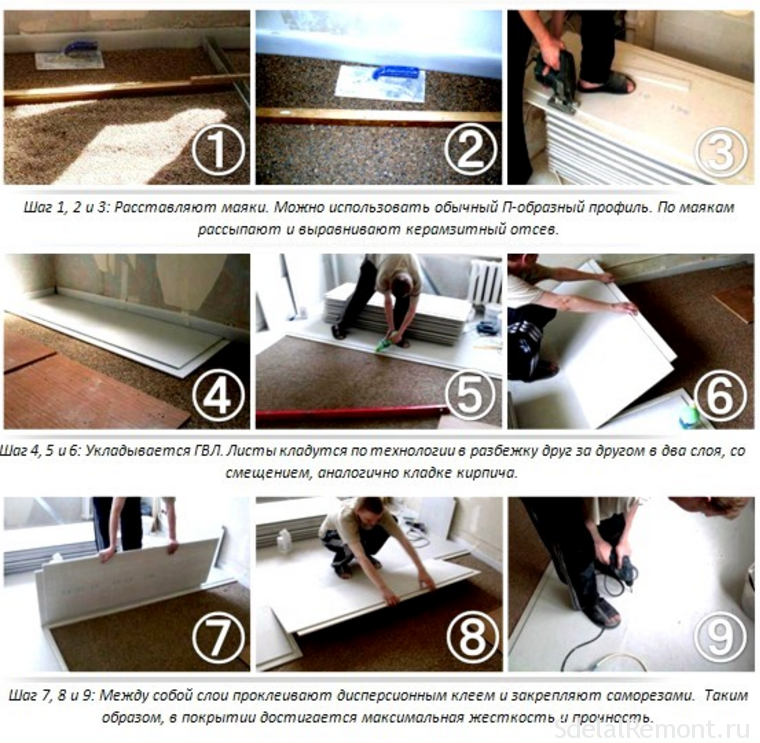

In the future there is an alignment surface. Dry screed floor with their hands on the technology provides two variants of the guide arrangement:

- Temporary. They were originally placed on the floor, and subsequently been regulated by the level of, selecting a certain height. It can be used, if there is a specific skill of dry backfill material without committing.

- Hard. Guides for dry screed its arms are fixed to the subfloor by means premix plaster and cement. After work on leveling, they remain.

Backfilling is carried out towards the entrance to the premises of the long angle. Care should be taken, all scattered evenly over the entire area. If you use the guide without fixing, the first one is installed near a wall, and the second - at a distance of less, than the length of the leveling rails. When all are exposed around the perimeter, filling level is checked and if necessary, it is added to the desired value. Tamping is performed only minimal. Will only remove the beacon from the room. So far arranged guides could without damaging the screed layer to remove, go eg plywood sheet, on which you can walk.

It makes no sense to put the heating cable in the thickness of expanded clay. Publish the heat will be "lost" and not come to the floor. Warm floor It is relevant only in the case of the use of infrared film. But their location should be directly under the floor covering.

installation of floor

Stacked sheet elements already in the final stage. dry floor device starts from the corner of the room. True masters of all in this situation, think differently, where necessary to start. fit, including the flooring of the entrance into the room.

Joints of sheets performed by the grooves and the location of locks. But before that, they should be coated with PVA glue, and later - to fasten with screws. Step between the screws choose better 15-20 cm.

Fastening GOLS is performed with screws with a head in the shape of a cone. This will allow him to "drown" in the list itself.

The joints are not permitted in the doorway in case, if performed simultaneously dry screed unit in several adjacent buildings. The indentation should be at least 30 cm. Each succeeding sheet is placed in a checkerboard pattern, Similarly,, as with masonry.

When the sheets are stacked, will only cut part of the waterproof film, which stands above the floor, and the damper strip. In addition, you can use sheets of gypsum fiber board and plywood, but it is best to perform all in two layers, not aside the "dressing" of joints.

The cost of work

total price, to align dry screed, It will depend on the area of the premises, and a backfill layer. Also do not play small value and the market value, which will differ from manufacturer. It is also important to choose the material itself and for backfilling. Plain concrete block will cost less, but proprietary blend eliminates the shrinkage and deformation of the floor.

cut costs, when it carried dry leveling the floor with their hands. There are on-site order 40% of the total cost of the purchased material to work. You can view some video on the web, that allow to carry out work as closely as possible and free from defects in the end.

conclusion

If dry floor screed with their hands the technology observed in full, then we get really high-quality base. It can be immediately used for the subsequent operation. The new floor is ready in a few days, that is markedly different from, such "wet" screed.

You can make a comparison with the costs of forces screed. Installation is much simpler, yes and no dirt on any of the stages. In addition to this you can add a high level of sound insulation, waterproofing and thermal insulation. Any elements not required for floor heating, yes and their use would be meaningless because the dry mixture.

When the need arises, such floors are easily dismantled. The main thing - remember the place, which ended with laying sheets. At this point it is more expedient to start work on "indiscriminately".