floor screed - must, an essential condition for the preparation of smooth floors. Dry floor screed with their hands hiding communication, It creates a perfectly flat surface for laying finishing flooring, perfect for laying laminate flooring with your own hands. The usual process using cement - a very time-consuming, time-consuming. It is difficult to produce a single person, but, Besides, cement to dry, to prevent cracks, in the floors have to moisturize every day is good for two weeks. Stack coating is possible only through 20 days. Site renovated apartment with his hands It continues every day to delight its readers with new and good articles with photos repair materials, and at the end you will find an example of video editing technology tie.

floor screed - must, an essential condition for the preparation of smooth floors. Dry floor screed with their hands hiding communication, It creates a perfectly flat surface for laying finishing flooring, perfect for laying laminate flooring with your own hands. The usual process using cement - a very time-consuming, time-consuming. It is difficult to produce a single person, but, Besides, cement to dry, to prevent cracks, in the floors have to moisturize every day is good for two weeks. Stack coating is possible only through 20 days. Site renovated apartment with his hands It continues every day to delight its readers with new and good articles with photos repair materials, and at the end you will find an example of video editing technology tie.

Dry floor screed in the apartment with his hands - introduction

To reduce this time, reduce to a minimum the work, but leave the tie as reliable, new material was invented - gypsum sheet, or GVL.

This material is based on two long-known materials - hybrid fibreboard (Fibreboard) with plasterboard sheet (GKL). It is prepared using the dry compression of the defibrated cellulose binder composition based on gypsum. A homogeneous, environmentally neutral building material ruggedized. The resulting fiber is fully compliant with firefighters, physicians. GVL has hygiene certificates, fire safety.

these elements, having a rectangular shape and one side polished, recommended to create dry screed at flooring, for facing of wooden walls. They go perfectly with any kind of floor covering, reduce the fire hazard.

these elements, having a rectangular shape and one side polished, recommended to create dry screed at flooring, for facing of wooden walls. They go perfectly with any kind of floor covering, reduce the fire hazard.

Gipsovolokno may be a conventional or moisture resistant, Consequently, its scope is not particularly limited. Especially, that there are different sizes of sheets. More common desyatimillimetrovye, measuring meter and a half. Sometimes the market can meet dvenadtsatimillimetrovye workpiece with a width of twenty meters. The most convenient - finished panels fold and recess, glued factory method, as shown in the photo. These panels are significantly accelerate the process of dry screed floor with their hands.

GVL hardly conducts heat, material is always pleasantly warm to the touch. Moreover, fiber under moisture draws in excess humidity from the room, and then, when the room gets too dry, sets it.

Technical features gipsovolokna, its light weight make when creating a floor screed do technological breaks, very shortens construction time. very light, GOLS sheets do not increase the pressure on the supporting structure, as it does ordinary cement. Fiber - excellent heat - sound insulator. Since the light sheets are perfectly amenable to cutting, they can be used in rooms of irregular or complex shape. It is indispensable to create curved ceilings, shaped baffles.

test, conducted and creators, and customers, show, in the wall, sheathed with a material very easy to drive in nails, but they are very difficult to pull out.

Gypsum fiber technology creates excellent dry screed, but in order, floors to meet all the requirements of strength, They are reliable, they need to be installed, strictly observing technology.

Apparatus dry floor screed

The algorithm works is as follows::

• With the old floor is removed linoleum, tile, any other cover. With the exposed concrete floor scavenge, It swept away the dust. Possible cracks old, carefully sealed with cement, Considering, the higher the number on the brand of solution, so it is more reliable. As well thoroughly shpaklyuyut joints between walls and floors. Can be used instead of cement or masonry ready mounting dry mixture.

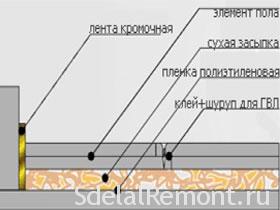

• Along the perimeter of the premises fit cut from mineral wool edge band (The photo shows the stacking belt, after coating film). Its optimum thickness / width - 10x10 cm, and the task - to absorb noise, not to give flooring to "walk", to prevent cracks.

• Along the perimeter of the premises fit cut from mineral wool edge band (The photo shows the stacking belt, after coating film). Its optimum thickness / width - 10x10 cm, and the task - to absorb noise, not to give flooring to "walk", to prevent cracks.

• Because of overlap sometimes too wet, as insulation against moisture spoils, the soffit is placed a layer of waterproof (PE) film. If the width is insufficient, that will have to carefully monitor the, to the cloth were laid overlapping. Otherwise, moisture will soak insulation, it will lose its properties.

installation of dry screed on the floor with their hands Technology

It was the turn of insulation. Dry mix for floor screed is different, such as bulk. Expanded, sand, pumice, chippings, a blast furnace slag is poured onto a polyethylene film, then well leveled. Usually used to create a horizontally predetermined beacons. The video example below shows how to align the dry mixture. Bulk compositions are very cheap, but to create a more or less good thermal insulation they need to pour a very thick - they do not hold heat.

It was the turn of insulation. Dry mix for floor screed is different, such as bulk. Expanded, sand, pumice, chippings, a blast furnace slag is poured onto a polyethylene film, then well leveled. Usually used to create a horizontally predetermined beacons. The video example below shows how to align the dry mixture. Bulk compositions are very cheap, but to create a more or less good thermal insulation they need to pour a very thick - they do not hold heat.

Polystyrene insulation much more reliable retain heat, They are not afraid of no moisture, no mice, no fungus, no time. They are more expensive than bulk, but their practical.

Properties are very similar or mineral fiber insulation: fiberglass, bazaltovaya wool. They are manufactured from molten glass or natural minerals, sometimes added to them poisonous formaldehyde. Such wool for residential buildings can not be used.

Polystyrene foam or fiber insulation cut to the size of the room, stacked on top of the waterproof film. Be sure to stack several layers, otherwise isolation will very fragile, unstable.

Installation of a dry screed GVL

Now you can do with your hands dry screed from gipsovolokna, simple installation. If the builders used the bulk insulation, the laying of the cut in advance considering the premises and edge band sheets GVL starts from the door. If other insulation, better to work from the window.

Plates of the first layer thoroughly coat with special glue, as shown in the photo to the left and at the bottom of the video, then already laid on top of it a second layer so GOLS, the layers abut one another. For greater reliability sheets are fastened together with screws with a corrosion-resistant coating. Then the floor is removed all unnecessary: clearances, marks smeared with putty fastenings, excess edge bands are cut. For greater reliability in rooms, which is too wet, floor plates, at the junction of the floor to the walls can be laid waterproof tape, and then to make the gypsum fiber insulation from any of the bituminous composition.

Plates of the first layer thoroughly coat with special glue, as shown in the photo to the left and at the bottom of the video, then already laid on top of it a second layer so GOLS, the layers abut one another. For greater reliability sheets are fastened together with screws with a corrosion-resistant coating. Then the floor is removed all unnecessary: clearances, marks smeared with putty fastenings, excess edge bands are cut. For greater reliability in rooms, which is too wet, floor plates, at the junction of the floor to the walls can be laid waterproof tape, and then to make the gypsum fiber insulation from any of the bituminous composition.

That finished dry floor screed video below shows all in an accelerated form. Under certain skills installation takes less than one day for every room, that does not go in any comparison with the installation of "wet" ties. GVL dry floor screed technology will significantly reduce the time until the final flooring. This option will not work of course, If you want to do assembling electric underfloor or set Radiant floor with their hands.

Fast dry screed video lesson

Video assembly instruction from Knauf - from the beginning of manufacturing, to install.