- Features of the instrument design

- An essential tool for repairing grinder Interskol

- Basic electrical faults Bulgarian Interskol

- Repair the control circuit grinders Interskol

- As repaired rotor grinders Interskol

- Stator Repair Bulgarian Interskol

- Mechanical faults Bulgarian Interskol

- Repair gear grinders angle grinders Interskol 125

- Repair gear grinders angle grinders Interskol 230

- Assembling the grinder Interskol

- How to assemble the gearbox Bulgarian Interskol

- How to assemble the grinder Interskol

- A few words about lubrication Bulgarian Interskol

- Video overhaul from Bulgaria Interskol

Grinders (Bulgarian) Interskol company is very reliable and durable. They have good performance and high dependability. But, improper operation of the tool, Failure to replace the carbon brushes, grease and bearings leads to premature failure of the.

Repair Bulgarian Interskol can be performed independently.

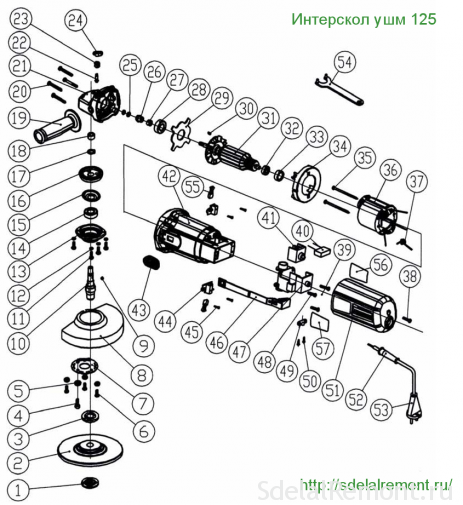

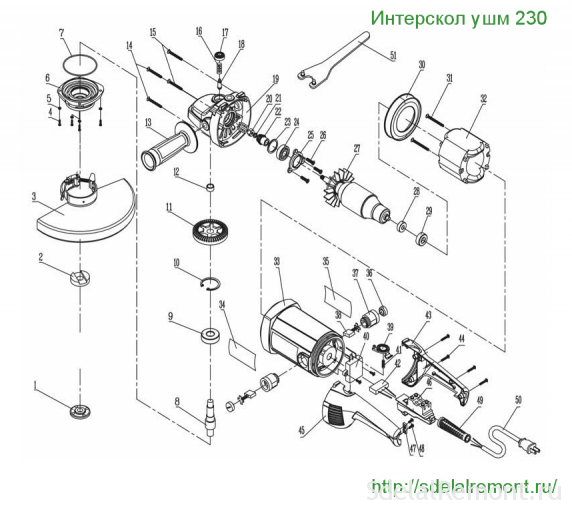

For this we need to know the device grinders Interskol, circuit assembly, the order of technological operations for disassembly and assembly of LBM. To properly perform the repair LBM Interskol, enough to consider the proposed scheme and the instructions.

Angle cars Interskol firms have recently become more and more popular not only in the professional environment, but also lovers of tinkering with his own hands.

Features of the instrument design

Interskol company is to develop the Russian leader, production and sale of various power tools, a recognized global manufacturers. Interskol products feature ergonomic, simplicity and ease of maintenance, environmental friendliness, increased power.

Bulgarian Interskol classified by the diameter of the disc: 115,125,150,180,230.

Among lovers of tinkering with his own hands The most popular is the Bulgarian Interskol two classes: with a diameter of the disc 125 mm 230 mm.

Several models are produced in representation of the class, differentiated by power.

In class 125 mm produced 4(four) models Interskol: UŞM 125/900, UŞM 125/1000, UŞM 125/1100, UShM 125 / 1400EL.

In class 230 mm produced 10(ten) models Interskol, differing from each other in power. Bulgarian Interskol class 230 available capacity, exceeding 2000 W.

Stands marking Interskol LBM 230/2300: angle grinder with a maximum diameter of the circle 230 mm, power 2300 W.

In bolgarok Interskol USM 125 driven gears are mounted on a spindle at the expense of key connection.

From Bulgaria Interskol USM 125 assembled in a single housing, serving as a handle.

In bolgarok Interskol USM 230 back of the case has a comfortable rear handle. This powerful professional machines with a two-handed design. In this class angle grinders driven gears are pressed onto the spindle shaft.

The proposed repair manual we will consider two classes of schemes bolgarok Interskol: UŞM 125, UŞM 230.

An essential tool for repairing grinder Interskol

LBM Interskol repair can not be made, not having a simple, the right tool. Repair the mechanical part of the Bulgarian Interskol will help you Screwdriver Set, carob keys, vise, hammer, press. For repair electrical circuits need a tester. Good, if you have the opportunity to apply the device type IR-2 finding short-circuited turns in the windings. Of the supporting materials will need lubrication, napkins, flushing liquid.

To perform high quality repair angle grinder family Interskol necessary to prepare the workplace, to choose the right lighting. semi, in a dark room quality repairs can not be performed.

To perform a repair grinders Interskol quickly and correctly, essential scheme of the Bulgarian, that you are going to repair.

Faults in the grinders are divided into mechanical and electrical.

Basic electrical faults Bulgarian Interskol

Usually, The most common cause of failure of the Bulgarian becomes an electrical fault. The basic failure rate Bulgarians on the electrical part is the failure of the carbon brushes.

Repair the control circuit grinders Interskol

the control circuit in bolgarok different models are slightly different from each other. All depends on the power tool, presence of innovations. Some grinders integrated electronic unit, regulating smooth start.

Circuit diagram of control circuits grinder Interskol LBM 125

The Bulgarian Interskol LBM 125 electro poz.55 attach special brush holders poz.44 , to get to where you can, Only by removing the rear cover of the stator housing poz.51 poz.42.

After removing the cover, it is necessary to unscrew the screws poz.50, holding the body of the brush holder.

Worn brushes is determined by the length of their residual. Carbon brush working length can not be less than 5 mm.

Power is supplied via the cable poz.53. The cable entry locations in the grinder and plug poz.53 cable may break off. The fault is eliminated by replacing the entire power cord or the failed part. twisting unacceptable.

The power cable supplies the voltage to the switch poz.41, inserted into the housing po47. is a lever for controlling the switch button poz.46. When performing maintenance on the purge lever incorporating silicone grease.

Circuit diagram of control circuits grinder Interskol LBM 230

The power cord is supplied to the switch poz.50 poz.46, connected to the electronic unit poz.40, carbon brushes poz.38, inserted into the brush holders poz.37. The electric grinders portion also includes a stator and a rotor poz.32 poz.27.

Replacing carbon brushes on the Bulgarian Interskol LBM 230 It does not require removal of back cover. Enough to unscrew the cap and remove the brush holder poz.36 brush holder with carbon brush. But to replace the circuit breaker, the electronic unit, a capacitor can be poz.42, just make out the back of the handle poz44,45. For this purpose it is necessary to unscrew four screws 4 × 16 poz.44.

As repaired rotor grinders Interskol

Yield rotor failure occurs for the following reasons:

- Load or have failed carbon brushes;

- Short circuit or open circuit windings;

- Load slat anchor collector:

- Collapsed or wedged rotor bearings.

Rotor repair requires specialized knowledge, instruments and equipment. It is preferable to buy a new rotor or be serviced by authorized service center. but remember, it costs money. To recommend osoboodarennyh rewind the rotor with your hands.

To disassemble the anchor bearing puller use. But can be applied to the means at hand. for example, vise, metal strips, hammer, nastavku soft metal.

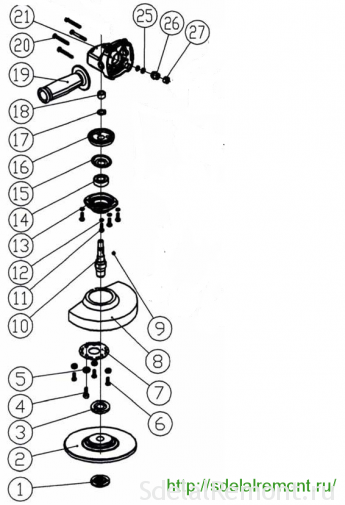

Dismounting of bearings with angle grinders anchor 125

The rotor poz.31 two bearings installed: rear, near the reservoir poz.32.

Size Bearing 608Z.

And on the side of the impeller bearing pos.28 size 6000-2 RS. Russian analogue 180100.

Removed rotor bearings after removal from the gear housing. To pull the rotor from the gear, it is necessary to remove the drive pinion bevel at 26, seated on the rotor shaft.

To do this, unscrew the nut M8 × 3.5 poz.25, dismantle the drive pinion Z = 12. She fixed keyed poz.30. Removable bearing puller.

Dismounting of bearings with angle grinders anchor 230

To remove the bearings with anchor poz.27, necessary to pull the rotor from the housing gear poz.19. Unscrew the nut M8 poz.20, Remove the lock washers poz.21, dismantle the leading gear poz.22. gently shaking, pull the rotor from the gear housing. Bearing remains in the gear housing. He closed bearing cover poz.25, which is attached to the gear case by three screws M5 × 8 at 26. In the gear case bearing set size 6201-2RS. Russian analogue 180201.

From the side of the bearing pos.28 collector is removed by using a stripper. Bearing size 608RT. Russian analogue 180608.

Stator Repair Bulgarian Interskol

Repair any stator grinder Interskol made after determining the nature of the error. Most often undercooked stator. This is because the instrument overheating. Stator fault indicates uncontrolled involuntary unwinding rotor grinders.

For stator repair you must remove it from the case. Check performance stator can be made and, without removing it from the case. But this can only be done in specialized shops. Or if you have short-circuited turns control device IC-2. Then define an open or short circuit in the stator windings can be, not demontiruya stator. Burnt stator removed, perematыvaetsya, or instead of installing a new.

Burnt stator can be rewound independently.

Rewind algorithm is as follows:

- Forward any way damaged winding from one edge;

- Count the number of windings, determine the direction of its winding, filling percentage of the stator core slot, measuring the diameter of wire;

- Removing the burnt winding, Clean core slots, check the insulation;

- Prepared wire wound into prepared grooves desired number of turns of the stator winding;

- Solder the ends of the windings, preliminarily putting them on an insulating wire;

- Impregnating the stator winding with AC;

- Stripping traces impregnating inside and outside of the stator housing;

- Checking the free movement of the rotor within the stator.

Video repair stator grinder Interskol own hands

Mechanical faults Bulgarian Interskol

Of mechanical faults in bolgarok Interskol weak point remains reducer. gears used in the gear wear out over time,, broken teeth, in compounds appears backlash.

Repair gear grinders angle grinders Interskol 125

For, to repair the gear grinders Interskol, necessary to establish the nature of the fault. Most gear mechanical faults determined visually, or listening. Large spindle shaft runout, jamming or cranking pinion gear are determined by simple visual inspection of the spindle shaft state. And increased running noise reducer, uncharacteristic sounds, overheating can be determined at the hearing, or touch the hand body.

To disassemble the gear necessary to untwist (4)four screws M4 × 14 pos.11, GROWER washers remove the control-1000ER position 12, pull the gear cover pos.13. It will be built in the spindle position 10. The spindle is mounted in bearing pos.14. Size Bearing 6201-2RZ. Russian analogue 180201.

For the spindle drive-out from the bearing housing should be afforded to the press. But you can gently knock and hammer. the main thing, not to damage the cover of the gear housing.

Conical toothed wheel pos.16 kept at keyed and fixed locking ring poz.17. As keys in the grinder Interskol LBM 125/900 applied bead diameter 3 mm. If you remove a lock ring, then remove the gears is not a big deal. In other models bolgarok Interskol LBM 125 key is used.

Remove the gears and check them for licking teeth, destruction or biting, the presence of backlash in key connection.

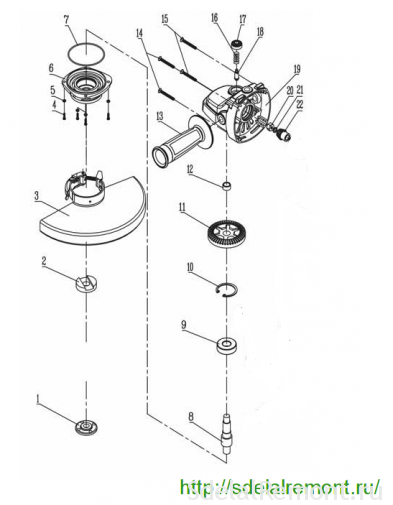

Repair gear grinders angle grinders Interskol 230

To disassemble the gear angle grinders 230 it is necessary to remove the cover pos.6, unscrewing 4(four) screw. The spindle position 8 is held in the bearing pos.9, zapressovanom the housing cover pos.6. Size Bearing 6203zz. Russian analogue 180203.

Gear wheel item 11 pressed onto the shaft with an interference fit. To take it off, You need to press. Craftsmen manage to shoot with a hammer, preheated gear.

Remove the gears and check them for licking teeth, their destruction.

Remont from Bulgaria Interskol USM 230

Assembling the grinder Interskol

Assembling the grinder Interskol is no different from other Bulgarians build brands. To assemble allowed serviceable, freed from old grease, parts and assemblies. The assembly consists of several stages.

How to assemble the gearbox Bulgarian Interskol

For gear unit assembly is necessary to collect the spindle, putting him the bearings and bevel gears.

Position 10 is put on the spindle of the gear housing cover pos.13, bearing pos.14, Bearing cover poz.15, conical toothed wheel pos.16. Pinion fixed on a spindle keyed. In ushm 125 used as key bead diameter 3 mm. For fixing the fixed spindle gear retaining ring poz.17. The assembled mandrel is inserted into needle bearing poz.18. A needle bearing is pressed into the gear housing poz.21.

LBM gear assembly 230 It begins with a spindle assembly site pos.8, onto which the bearing pos.9, circlip position 10. Toothed wheel pressed onto the spindle on item 11. The spindle is inserted into the roller bearing position 12. Size Bearing NK1210.

To facilitate the pressing process driven gear pos.11 on the spindle pos.8 heat and cool gear spindle.

How to assemble the grinder Interskol

collection algorithm Bulgarian Interskol next:

- The body is inserted into the stator;

- The stator is covered with plastic protection;

- The stator is inserted into the rotor with a protected rubber sleeve on the bearing reservoir;

- The second rotor end is inserted into the gear housing;

- The rotor drive gear is pushed and fixed by a nut with right-hand thread;

- gear housing is attached to the stator housing with four screws;

- Checks smooth rotation of the rotor;

- On the gear housing cap is worn with the driven gear;

- twists 4(four) screw fastening gear cover;

- Checks smooth rotation tool spindle;

- Mounted carbon brushes;

- Wearable or going back cover handle;

- Made a test run the tool, checked for smooth operation.

According to the given algorithm collects all without exception, the Bulgarian family Interskol.

Several features in the disassembly and assembly of the Bulgarian Interskol:

- To remove all the old grease from the gearbox housing, the last best professional hairdryer to warm up to a liquid lubricant and then delete it;

- In some models, Bulgarians Interskol pinion gear fixed to the shaft with two nuts, one of which is a locking key S = 12;

- Gently unroll or tighten the lock nut of the driven gear rotor grinder Interskol LBM 115;

- Lay in the gear case lubrication, component is less than half its volume;

- When disassembling carefully inspect the condition of the commutator bars, it should be no traces of burning and depleted tracks.

A few words about lubrication Bulgarian Interskol

Before assembling the mechanical components grinder Interskol, without fail, Details of the recommended grease grease. In the Russian market of lubricants lubricants are well represented foreign and Russian manufacturers. Today, you can buy high-quality lubricants domestic manufacturer. They are in no way inferior in quality to foreign analogues, but there are several times cheaper.

special grease designed for gear grinders, possessing high adhesion. Adhesion is a property of a substance to bond with the lubricated surface.

findings:

- choosing grinders, opt for the Russian angle grinder firm Interskol;

- You get a reliable, durable, ergonomic, cheap tool;

- Preference was given to Bulgarian Interskol class angle grinders 125;

- In the household, they are more in demand and are safe.

I wish you success!

Video overhaul from Bulgaria Interskol