- Assembling the mechanical parts of the gun Hitachi DH24PC3

- Assembling countershaft perforator

- barrel assembly percussive punch mechanism

- Assembling the impact mechanism

- Setting the mode switch knob

- Keyless chuck assembly

- Assembling electrical perforator Hitachi DH24PC3

- stator assembly

- the rotor assembly

- Assembling the control circuits

Perforator assembly Hitachi DH24PS3 may implement any user, He has the skills and metalworker who knows the general rules for operation with electrical.

Before starting the assembly of the gun, Prepare the workplace, a set of new rubber products, necessary lubricants, instruments, tester.

the gun assembly is divided into several stages.

Assembling the mechanical parts of the gun Hitachi DH24PC3

The assembly starts with the mechanical part of the assembly of hotel nodes, included in the block.

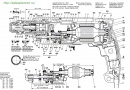

Assembling countershaft perforator

The intermediate shaft is part of the gun gear and performs two functions:

- transmits torque to the trunk punch;

- converts the torque into reciprocating impulse due to operation of the bearing drunk.

The shaft bearing poz.52 worn drunk poz.53, helical large gear poz.54, the metal ring and the bearing poz.55 poz.56.

The perforator Hitachi DH24PC3 bearings used in Japan such as 626VVM. Bearing Dimensions 6x19x6. You can replace the Russian analogue type 26.

drunk bearing, helical gear, bearing grease smeared. From domestic counterparts firms recommended lubricant Nanohim, It is marked as the PM or by marking Nanotech Metallplak Electra.

On the other hand on the shaft fits poz.51 clutch, clamping spring poz.50, spur gear poz.49, poz.48 mode selector lever, metal sleeve poz.47.

Assembled shaft is inserted into the inner casing perforator poz.41.

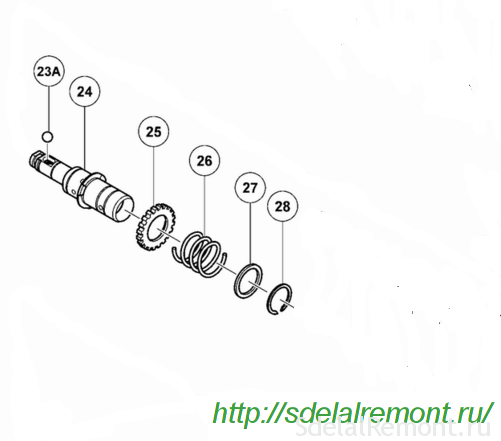

barrel assembly percussive punch mechanism

To begin assembly of the shock punch mechanism, must be pressed into the cover of the mechanical block body assembled gun barrel.

On the trunk poz.24 worn spur gear poz.25, Coil spring at 26, steel washer

M30 poz.27, retainer ring pos.28.

The housing assembly of mechanical press in bearing blocks must poz.15, which, in turn, pressed the barrel itself.

The housing item 10 are inserted:

- the oil seal item 12;

- the hammer sleeve pos.13;

- Felt seals pos.14;

- zapressovyvaetsâ Bearing 6904DD poz.15;

- restrictive inserted metal sleeve pos.16;

- all fixed lock ring poz.17.

For pressing the bearing using a press, a handmade wooden nastavku.

The outer bearing holder before installing the pre-lubricated with grease.

The housing abuts end position 10 into a cylindrical gasket of aluminum, copper or wood.

Bearing embedded in the body and with the help of a hammer and pressed nastavki. When pressing is not allowed distortions.

Assembled shaft insert into the housing and press-fit, being careful.

Pressing is carried out using a press or vise with a simple device. As an adaptation nastavku use of wood or soft material.

assembly Boykov

The punch used two types of strikers.

Poz.29 firing pin and firing pin pos 37. the striker assembly is equipped on their rubber sealing rings with grease mandatory. From domestic lubricants best grease Ciatim-224 GOST 9433-80, Inert to rubber products.

On the striker poz.29, except for the rubber sealing rings, worn shock mount mechanism poz.31, Damping sleeve poz.35, circlip poz.36. Ring captures details on the striker.

On the striker poz.37. worn rubber sealing ring pos. 38. The firing pin is lubricated with grease Ciatim-224 and is inserted into the sleeve piston poz.39.

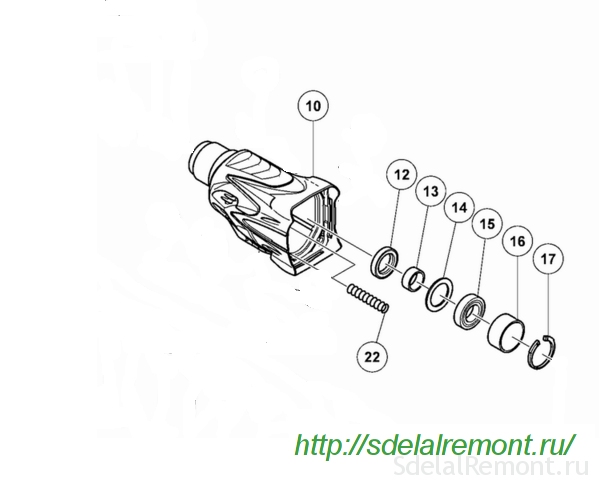

the piston sleeve assembly

To assemble the piston sleeve, must be inserted into her ears piston pin poz.42, after inserting steel washers M30 poz.43.

Assembling the impact mechanism

Remaining in the inner housing insert assembled poz.41 countershaft poz.52, articulate shank drunk poz.53 bearing and piston pin poz.42, inserted in advance in the ears of the piston sleeve poz.39.

When assembling the barrel, when you insert it in Jaunty, be sure to lubricate the inner surface of the piston.

The entire assembly process is accompanied by the use of those types of grease, specified by the manufacturer or the perforator respective domestic lubricants.

Setting the mode switch knob

Combining the mechanical part and the stator unit, Installation can proceed to handle the mode switch.

Handle poz.21V mode switch is set below the housing.

To insert it into the housing and fix it, must:

- Insert the handle spring poz.19;

- insert fixing red button poz.18;

- Wear rubber caul poz.20.

Insert the handle clockwise to the body to "blow", turn back on 15 degrees until it clicks. handle locks.

Keyless chuck assembly

Hammers Hitachi DH24PC3 equipped with keyless chuck type SDS-plus.

Chuck mounted on the last stage of the punch assembly.

On the barrel projecting shaft is put in a seal pos.7 sequence, conical spring pos.6, washer pos.5.

In the next step, insert locking ball poz.23A. ball Marking 335300.

On the shaft is worn metal ring pos.4. The cartridge is closed lid position 3, all the fixed stop ring pos.2, on the front end of the shaft fits protective cap Pos.1.

Mechanical part of the punch Hitachi DH24PC3 collected.

Remember! When assembling the mechanical parts, observe the rules of application of lubricants, use only those, that recommended by the manufacturer or domestic, specially designed for rotary hammers.

Assembling electrical perforator Hitachi DH24PC3

Divide perforator assembly of the electrical part at points.

stator assembly

Refurbished or new stator poz.65 set poz.68 the stator housing and is secured by means of fixing screws M4 × 50 poz.64. Article stator 340635F.

Top stator closed poz.63 guide motor impeller. stator leads are displayed on the control button poz.70V.

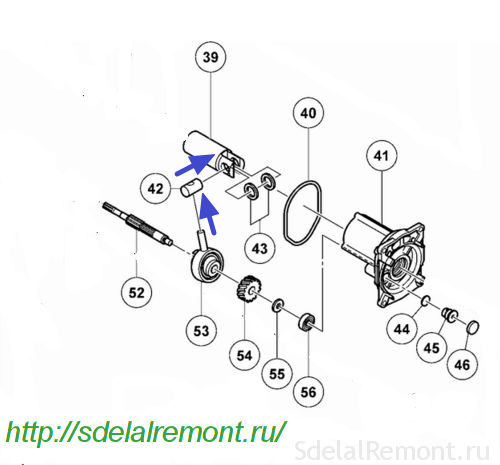

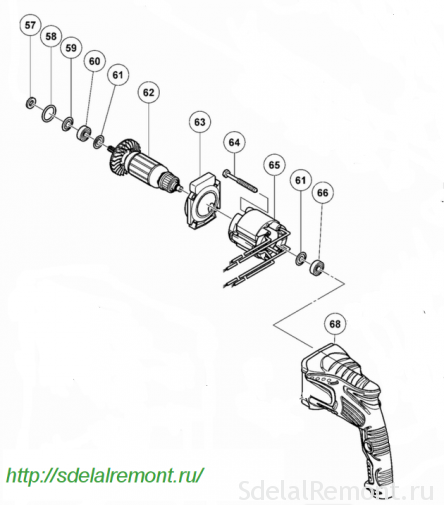

the rotor assembly

The punch used anchor motor 220-230V, item 360720E.

New or renovated their hands poz.62 rotor is installed in the slot in the inner housing poz.41, pre worn on the rotor shaft felt pad poz.57, O-ring poz.58, gasket poz.59, bearing 608DDM, poz.60 and steel strip poz.61. Bearing Dimensions 8x22x7, Russian analogue 80018.

The rotor is inserted into the helical gear in mechanical perforator unit.

It remains to connect the mechanical unit and the stator housing.

When you insert the rotor into the stator housing, preliminarily remove carbon brush together with the brush holder.

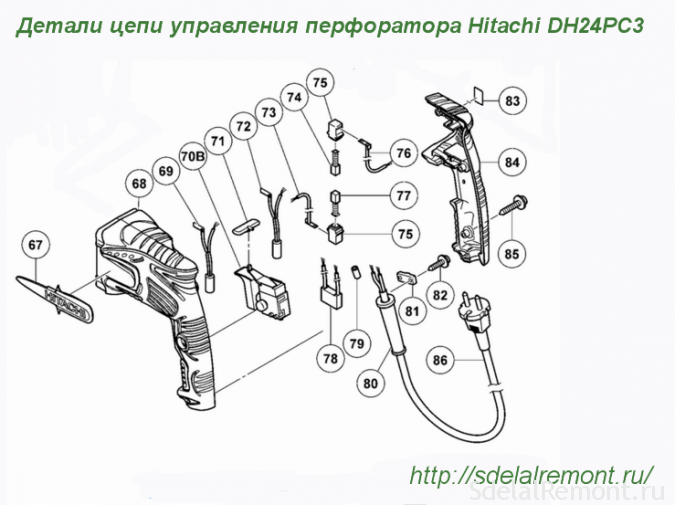

Assembling the control circuits

Control circuits are circuit, allowing smoothly run puncher, adjust the frequency and speed of his work.

The perforator Hitachi DH23PC3 used coal electro poz.74, 77 c hitchhiking. Hitchhiking can not include punch, If brushes are worn more than permissible norms.

The carbon brushes have a hitch article 999072, conventional brushes article 999041. The carbon brushes in the brush holder fixed perforator housing poz.75, article 955203.

In some embodiments, the throttle poz.69 used and a diode contact poz.72.

The power supply circuit is included noise suppression capacitor poz.78.

The punch 220 is used pushbutton (OLD 331454/324536). article 335796. Switch Type TG801TSBU-1.

Details of the control circuit are mounted within the handle housing stator.

Connect punch to AC, check the operation in all modes. Make smooth adjustments and the punch without fanfare.

Everything!