Increase uptime perforator Hitachi DH24PC3 contributes to timely compliance with maintenance deadlines.

Maintenance punch is timely replacement of rubber O-rings, grease, worn parts.

The rotary hammers Hitachi DH24PC3 recommended to use those types of lubricants, which advises the manufacturer. A manufacturer recommends a lubricant, specially designed for rotary Hitachi. Hitachi hammer drill is considered Japanese, although it made in China.

Greases are divided by type:

- in liquid lubricants, is a purified petroleum oils with additives, It is used for lubrication of high-speed, legkonagruzhaemyh nodes;

- on plastic or lubricating oil lubricants, made from synthetic or mineral oils with various additives and thickeners.

The main characteristic of the lubricant is determined by its viscosity, acid number, melting point.

Features oils, Tool used by manufacturers, often kept secret. This is done, to the user, bought tools of a firm is not puzzling, and bought grease, recommended by the manufacturer tool.

The perforators recommended plastic lubricants, designed for bearing tyazhelonagruzhnyh, who work in a part of the reverse, at low speeds. In addition the grease in the punch performs the role of a sealant and preservative.

Knowing the requirements and conditions of the individual perforating units, you can pick up grease from the group of domestic lubricants.

From domestic lubricants possess similar characteristics such lubricants, both Lithol-24, CIAT-203, TsIATIM-221F.

What a lubricant is used in the punch Hitachi DH24PC3

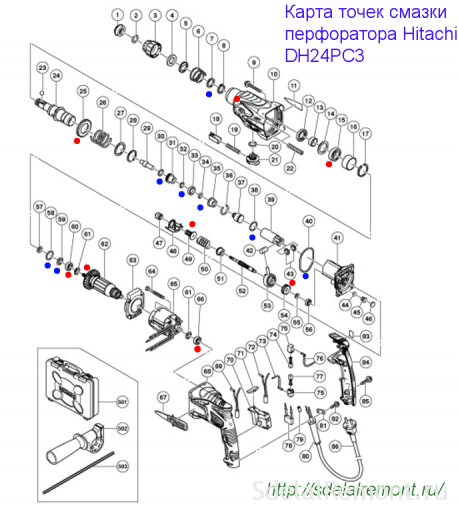

The rotary hammers Hitachi DH24PC3 are three types of lubricants: for bearings and gears, for rubber O-rings, for shank drills.

Any grease must meet certain requirements:

- the desired viscosity;

- melting or ignition temperatures;

- shear strength;

- dropping point.

The Hitachi rotary hammers are used bearings, do not require additional lubrication. However, when mounting a bearing to lubricate its socket and the outer diameter of the cage must be.

The following bearings are used in the perforator Hitachi DH24PC3:

- Bearing 37 mm, article 6904DD, size 20x37x9, Russian analogue 1000904, poz.15;

- Bearing 19 mm, item 626VVM, dimensions 6x19x6, Russian analogue 26, poz.56;

- Bearing 22 mm, item 608DDM, dimensions 8x22x7, Russian analogue 80018, poz.60;

- Bearing 22 mm, item 608VVM, Dimensions 8x22x7, the Russian equivalent of 60018, poz.66.

The new grease is applied to the surface washed clean of parts or assembly.

Grease disassembled the gun has a dark muddy color. This color is due to the wear of metal parts and rubber sealing rings.

Prior to assembly all parts are thoroughly washed in kerosene or petrol and dry.

Do not allow solvents to Rubber Products.

Be sure to replace the grease.

Lubrication of bearings and gearboxes

Usually, in rotary hammers are used bearings, dressed with the required grease. However, when installing the bearings to be lubricated socket for better compaction.

Bearing 6904DD poz.15 mounted in the housing position 10, which is pressed into the barrel poz.24. Bearing impact shock loads.

crimping the barrel assembly preferably special grease lubricant company Hitachi. But domestic lubricants manufacturers provide at least good results. The photo shows lubricant, produced by Russian manufacturers specifically for the lubrication of gearboxes.

It is recommended for lubrication of gear, gears, Clutch Bearing drunk.

Grease the rubber O-rings

Rubber O-rings during operation undergo the strong heating due to friction and air pressure in the piston. If the O-rings are not lubricated, friction increases, which leads to more heat. Installing new O-rings, be sure to lubricate the place of their installation. We recommend using Hitachi's grease.

But if you lubricate the rubber sealing ring of the domestic lubricant, whose dropping point higher than + 100 °, the result is good enough. the main thing , use a lubricant, which has not only high lubricity, but also has sealing properties.

It is best to use the domestic lubricant Litol 24.

There are two warnings:

- If your instrument warranty, and you decide to conduct their own technical services, it is recommended to use the lubricants, who insists to apply the manufacturer;

- lubrication of domestic manufacturers maintain their properties in less time and requires more frequent replacement.

Lubricants for shank drills

Hammers Hitachi DH24PC3 equipped with keyless chuck type SDS-plus. cartridge design involves the use of a special working tool shank. Reliability gripping the tool shank provided special design. But in the course of work is required to periodically change the tool.

specialty lubricants are used for easy disconnection of the tool from the keyless chuck.

Usually, manufacturers Drifters recommended to use special lubricants for drilling. Lubricants are used for lubrication in rotary hammers drills Hitachi DH24PC3, developed by Hitachi.

Russian manufacturers produced a number of lubricants, which at equal lubricating properties are much cheaper.

Lubricants for domestic manufacturers

A few words about the Russian lubricants.

Grease Litol-24 manufactured according to GOST 21150-87 based on a mixture of mineral oil and lithium soap. The mixture is added to anti-acid and adhesive additives.

Lithol-24 recommended for use in friction units, rolling and sliding bearings, gears where the operating temperature does not exceed + 120 ° C.

Lubrication Ciatim-203 produced according to GOST 8773-73 transformer oil from the oil with the addition of a lithium soap as a thickener and asidola and additives to increase the viscosity and enhance protivozadirov. It recommended for lubrication shank drills in keyless chuck SDS.

Grease Ciatim-224 manufactured according to GOST 9433-80, It is a heat-resistant silicone fluid, as a thickening agent added soap with anti-acid additive. Lubrication is inert to the rubber, and it is recommended to lubricate O-rings.

findings:

- the use of lubricants domestic producers permitted;

- domestic lubricants significantly cheaper;

- Russian producers applying lubricant, remember, that their replacement should be more frequent;

- Do not allow the instrument overheating, Do not exert pressure on the tool in the "Blow" mode;

- constantly check the condition of the carbon brushes;

- if funds are available, use those lubricants, that recommended by the manufacturer of tools.