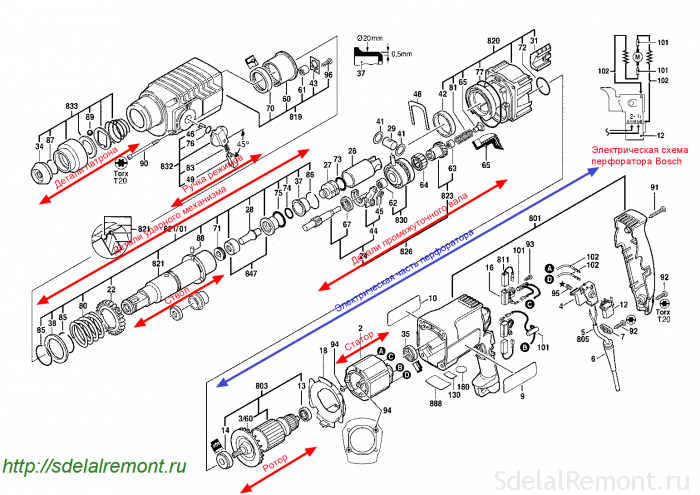

The operating principle of Bosch rotary hammer 2-26 can not be distinguished from the well-known brands hammers.

The rotating rotor transmits torque to the countershaft mechanical perforator assembly, simultaneously transmitting the translational motion through the rolling bearing on the hammer mechanism and shock pulse perforator. In the working tool with the torque transmitted translational shock pulse. This principle is implemented in all rotary hammers.

But various firms, produce punches, has its own design features.

Bosch Hammers are considered the best in the segment of power tools. But there is nothing eternal.

If your Bosch hammer drill 2-20, 2-24, 2-26 stopped working, then it can be restored by yourself. It is necessary to have basic skills and little understanding of the mechanic in electrical engineering.

And another important detail, Bosch rotary hammer's simple design, does not cause difficulties in the repair.

When repairing power, including repair hammers Bosch, Always follow basic safety precautions when working with electrical appliances.

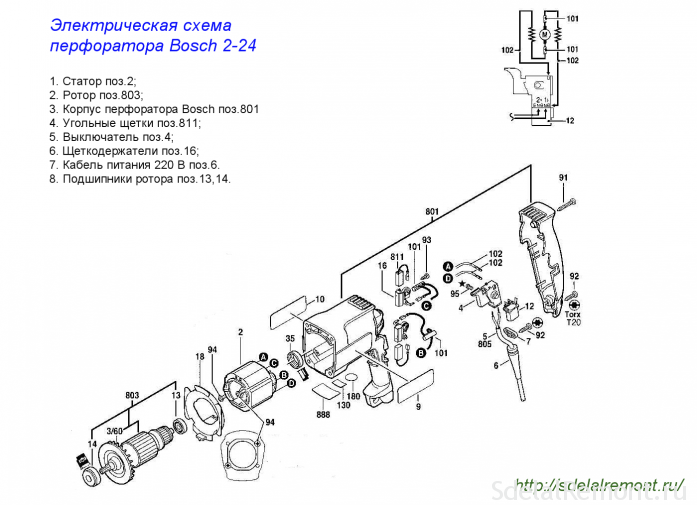

To help repair the Bosch rotary hammer, You should learn how the tool is assembled.:

Any dismantling of the gun bosch 2-26 begin after inspection, Trial inclusion and identify the causes of device failure.

Video disassembling the gun Bosch 2-26

The procedure for disassembling the gun Bosch 2-26

Since the order of disassembly rotary hammers Bosch 2-20; 2-24; 2-26 practically the same, consider the sequence of dismantling the example of Bosch rotary hammer 2-26.

Dismantling the gun Bosch GBH 2-26 dre begins with disassembly of the quick chuck.

Disassembly of the quick chuck

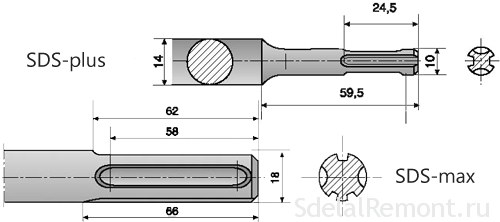

The Hammers Bosch commonly used two kinds of cartridges: cartridges SDS-plus and SDS-max ammo. The difference in principle clamp the tail part of the working body.

Bosch cartridge perforator device structure differs landing tool rods depending on SDS-plus model or SDS-max. In addition to these types of cartridges found SDS-top chucks, SDS-quick.

The procedure for disassembling the gun cartridge Bosch 2-26 plain:

- Remove the rubber tip poz.34;

- remove the circlip poz.87;

- remove steel washer poz.833;

- remove the conical spring poz.833;

- neatly, not to lose, using a magnet, remove bochonochnye balls poz.89.

Carefully inspect all parts of the cartridge.

SDS-plus chucks are designed specifically to tools for drilling. The diameter of the tool shank is 10 mm, the tool length in the range of 110 ... 1000 mm. Boers diameter lies in the range 4 ... 26 mm.

Removing the mode switch

Putting to one side the punch, remove poz.832 mode switch.

First, turn the switch to the "Drilling", Press the screwdriver fully into the end of the toggle button (it is red) and turn the dial counterclockwise at an angle of 70º.

Shaking the dial, pull out the dial from the housing.

Dismantling of the hammer assembly

Putting perforator Bosch 2-26 vertically on the knob, Unscrew the four screws poz.90, mechanical holding cap assembly housing.

Click on the impactor shaft end and remove the cover. Cover plastic black.

Now it is necessary to remove the shaft and the intermediate shaft poz.821 poz.826. They are nothing more than not fixed.

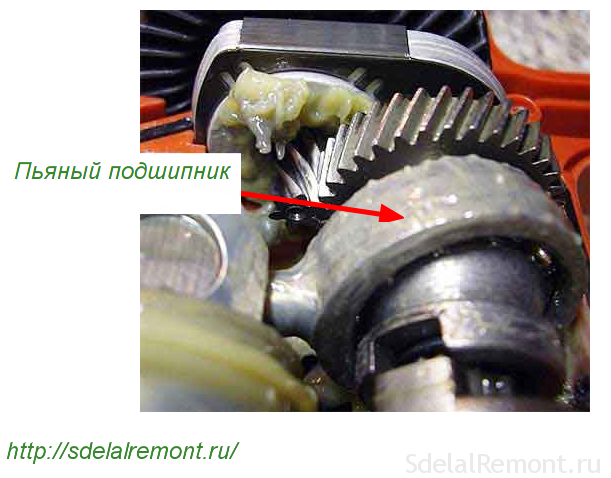

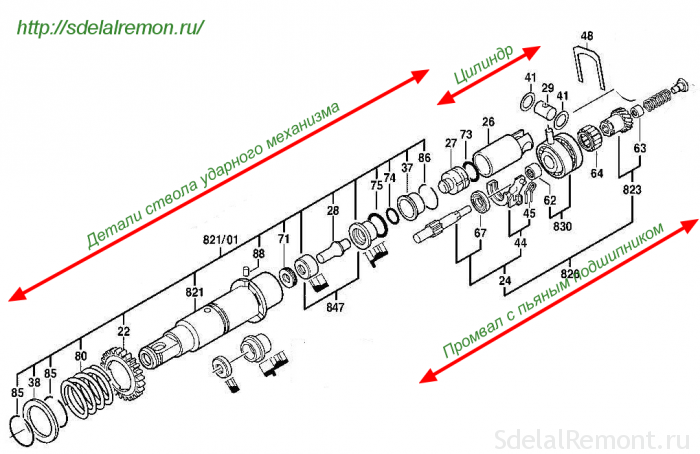

Then use a screwdriver is necessary to remove the bracket poz.48 rolling bearing poz.830. by the way, in a simple way, he is called "drunken bearing". progressively lifted: sleeve at 26 and "drunken bearing".

Disassembly the hammer barrel

- disassembly of gun barrel assembly Bosch start from the cavity, She took out the cylinder at 26 with drummer poz.27;

- from the cavity it is necessary to reach the firing pin assembly;

- by the chuck shaft remove circlip poz.85, poz.38 steel ring and another retaining ring poz.85;

- remove the spur gear poz.22.

Disassembling the cylinder

Inside the cylinder is inserted drummer poz.27, from which it is necessary to remove the rubber ring poz.73. When any disassembly of the rubber parts must be replaced without fail.

At the opposite end of the cylinder is inserted into the hinge poz.29 and two flat washers poz.41.

Dismantling countershaft

Intermediate shaft disassembled removing poz.24 shaft and pulling out from the housing poz.77, "drunken bearing".

The bearings are removed either manually , Or using a bearing puller.

Uncharacteristic fault Hammers Bosch

Bosch rotary hammers are extremely reliable. But there are faults, almost never occur in practice. The following is one of them.

Bosch rotary hammer drills, but do not hammer

If puncher stopped to peck, but it allows you to drill, the most likely cause of the destruction can be "drunk Bearing". This fault does not occur often, and find it is not easy.

To eliminate it is not necessary to go to the repair shop. The fault could be fixed at home depending on how handy you are..

First it is necessary to disassemble drill Bosch countershaft. Disassembly Procedure given above.

After removing the intermediate shaft, you get to the "drunken Bearing". Blow rolling bearing indicates a broken clip, scattered beads, pieces clips.

took out bearing, Removes dirt, all parts of the destroyed mechanism.

You buy a new "drunk bearing", and, Lubricate all parts with new grease, Replace and assembly, in sequence, reverse disassembly steps.

Disassembly electrical perforator Bosch 2-26

Dismantling the gun Bosch 2-26, its electrical, It begins with the removal of the rear cover on the handle of gun, Remove the three screws.

The next step is to take out the reverse switch.

Turn it to the neutral position and lift the. reverse switch is removed.

To remove the need to cover the stator, holding in his right hand mechanical assembly, and to the left of the stator housing, drag them apart, pokachivaya.

stator cover of the.

sufficient drag for the rotor of a mechanical separation assembly apart these parts. The rotor is mounted in the mechanical assembly of small spur gear, inserted into contact with the large spur gear mechanical assembly.

The rotor is released and can carefully examine the condition of the collector, bearing.

To remove the stator, enough to remove the protective plastic protective cover, and knock on wood blocks or mallet on the end of the housing, in which the stator is inserted. Prior to this, do not forget to unscrew the two screws, securing the stator housing.

The stator is removed, rotor got, you can violate their inspection and fault detection of all details, a part of the electrical part of Bosch rotary hammer.

When viewed from the disassembled Hammers Bosch 2-26 pay attention to the state of the carbon brushes, raid on the brush holders and reliability of their attachment, Reversing switch contacts integrity, of wire in place at the entrance to the punch.

brushes length should not be shorter than 8 mm. On the brush holders should be no traces of sparks and carbon dust from brushes, the reverse switch contacts perforator Bosch 2-26 there should be no burnouts or damage contacts.

At this demolition is over.

I wish you success!