- The procedure for disassembling the gun

- Video instructions for disassembling the handle punch mode switch Makita 2450

- The procedure for disassembling the cartridge punch Makita

- The order of assembly of the quick chuck

- understandable gear

- Fault stops the drill when drilling with impact

- Video fast disassembling the gun Makita

Due to the dust, dirt and moisture internal lubrication with time becomes hard and does not carry out its mission. Puncher starts is noisy. Getting puncher repair, Please read the attached instructions for disassembly, grease, assembling units Makita rotary hammer 2450, 2470. Scheme punch Makita 2450 and 2470 It will help to disassemble defective parts, find defective parts. And also describe how to disassemble drill Makita 2450.

Disassembly punch Makita 2470 It begins with the removal of the mode switch knob.

The procedure for disassembling the gun

Place the hammer on a clean surface.

Analyzing the mechanical part of the perforator Makita 2450 see или 2470, always necessary to remove the handle of the mode switch.

At the beginning of the pen is "Blow" mode (the extreme right in a clockwise direction). Podkovyrivaetsya on the handle and lifted the latch with a screwdriver.

Podkovyrivaetsya on the handle and lifted the latch with a screwdriver. After removal of the latch, pen translates to the left, in the "Drilling" mode.

After removal of the latch, pen translates to the left, in the "Drilling" mode.

Sandwiched fingers pen is removed from the housing slot.

Video instructions for disassembling the handle punch mode switch Makita 2450

The order of the mode knob

To set the mode selector switch into the housing, you need to make some action:

• Insert the switch to the "drilling" in the mounting slot until it clicks into place;

• turn the switch anti-clockwise to the "impact";

• transfer switch with a click counter-clockwise to the position "drilling";

• Insert the spring-loaded and the red button;

• insert the top cover until it locks.

Mode switch is assembled.

In the second stage must be disassembled quick chuck and to repair the gun cartridge with your hands. by the way, chuck requires disassembly only Makita models 2470. cartridge device rather simple, and its repair will cope anyone, little or less owns the locksmith skills.

The procedure for disassembling the cartridge punch Makita

Repair Hammer chuck begins with the installation of the gun vertically on the case back. Properly perform the work on dismantling the scheme will punch hrmakita.

A replacement cartridge if necessary perforator makita 2470? The answer can only be obtained after a complete disassembly of the cartridge with your hands.

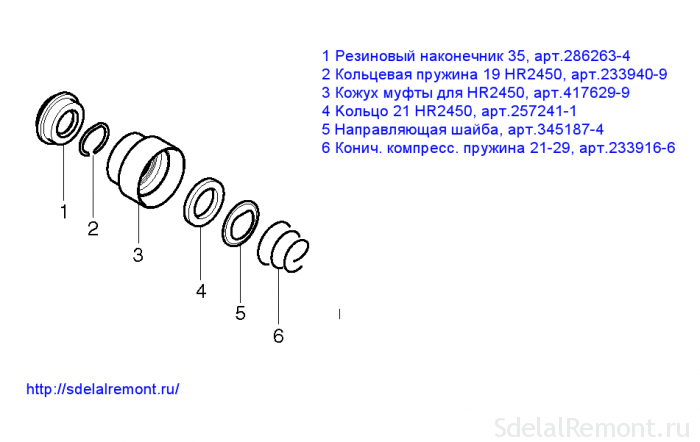

Using a screwdriver or remover removed duster, cartridge is released from the retaining ring, clutch housing, metal ring 20 pos.4. Then it is necessary to carefully control the ball poz.20, remove guide pos.5 washer and conical spring pos.6, his fellow. Patron harvested.

The diagram below illustrates the perforator cartridge device.

The basic malfunctions perforator makita 2450, causing defects in the chuck, are:

- wear protective rubber anther position 1;

- relaxation of the retaining ring position 2 or its partial wear;

- poz.20 ball wear;

- loss conical spring elasticity or tensile pos.6.

Repair punch holder is not a complicated procedure and is usually easily accomplished by anyone, which can hold a screwdriver in his hands.

If replacement Wiper, locking ring, conical spring do not represent the complexity of, the replacement of the new ball requires attention. The new ball should have a size of 7mm diameter ± 1 mm.

As lubricants recommended special grease, designed to punch Makita.

Grease has an index Makita P-08361, Makita 183477-5 SDS-PLUS 30g for gear. For shank drills recommended lubricant Makita 196804-7.

collecting cartridge, conical spring mount narrow side to the punch.

Do not forget, repair cartridge punch with your hands require care by collecting.

The order of assembly of the quick chuck

Assembly is done on a clean surface. Details of the pre-rinsed, dried and lubricated with a thin layer of lubricant recommended.

the gearbox shaft is lubricated with grease Makita 183477-5 SDS-PLUS. On the shaft in a sequence going all incoming chuck parts.

Setting the conical spring pos.6, put pos.5 guide washer and lock the ball poz.20, inserting it into the groove of the gear shaft.

Remaining wear ring pos.4, pos.3 coupling guard, lock parts lock ringlet pos.2. In the last step, insert the cartridge in a protective tip end position 1

Overhaul cartridge punch Makita 2450 this is over. It remains to verify its quality, inserting a drill chuck. When properly assembled chuck holds the drill from spontaneous falling out.

The cartridge is assembled.

understandable gear

To get to the mechanical part, We need to remove the plastic casing.

An order of dismantling mechanical punch Makita

Initially remove the protective plastic black housing. The housing is removed after, how do you remove the four screws, securing an end housing.

Pushing the shaft end you squeeze out of the gearbox housing.

removing body, it is necessary to separate the rotor from the gear. Reducer called the total mechanical part.

Separates the rotor from mechanics(reducer) simply.

Right hand is necessary to clamp the gearbox, left clamp rotor.

Pokachivaya, Pull both sides in opposite directions. The rotor is held in the gearbox due to friction bevel gears.

Main fault perforator Makita occur in mechanical parts of the instrument.

The most characteristic part of the problem for the mechanical, failure of the hammer.

Dismantling of the striking mechanism

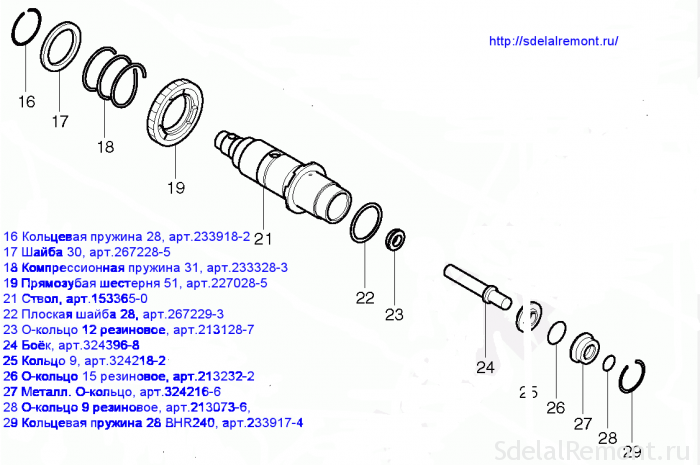

The firing mechanism assembled on the inner casing and consists of a gearbox shaft and the intermediate shaft.

The rotary movement is transmitted via the helical gears on the intermediate shaft.

Gear shaft is a hollow shaft, in which the cylinder moves freely.

Fitted on the intermediate shaft a small spur gear transmits a rotation of the large spur gear reducer shaft, wherein the impact mechanism is mounted.

A translational movement in the percussion mechanism gear shaft simultaneously transmitted due to transmission of the rolling bearing of the intermediate shaft to the cylinder, the moving gear in the trunk.

We proceed to the dismantling of the intermediate shaft.

Dismantling countershaft

The shaft helical gear poz.40 planted poz.42, which rotation is transmitted from the rotor pinion, rolling bearing 608zz poz.41, which transmits the translational movement of the piston on the hinge poz.34 poz.32.

On the other hand shaft mounted clutch poz.39, spur gear 10 poz.80, compression spring poz.38, circlip S-7 poz.37, bearing 606zz poz.36

Particular attention should be paid to the condition of rolling bearings.

The punch set of imported bearings. You can install domestic bearings.

606zz bearings can be replaced by 80016, bearing 609zz changes to 80019.

Proceed to disassemble the shock mechanical shaft

Disassembly shaft impactor

Bork Barrel punch Makita 2470 It is a simple process, if use circuit device perforator Makita.

Val represents trunk poz.21, wherein the hammer mechanism is assembled.

On the trunk mounted gear poz.19, which is pressed by a spring poz.18, poz.17 through the washer and circlip is fixed pos.16.

The barrel cylinder is moved poz.32, acting on the firing pin pos 24. On the reverse side of the striker is fixed a metal ring poz.27, transmitting an impact on the drill.

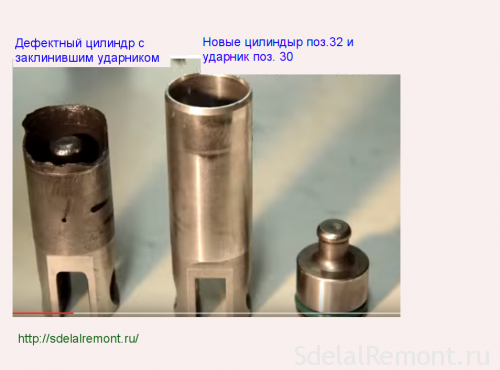

And when the need to replace the gun barrel?

Most often it comes down the metal ring.

paint

Cylinder with drummer

With disassembly, we figured out.

Fault stops the drill when drilling with impact

Reasons when Makita rotary hammer drill with a bang, and the drill is rotated tooth wear safety gear and the teeth of the barrel. Often, this error occurs when using the gun as a mixer for mixing mixtures. When the slips Safety clutch, and given the spring load, the load is large.

Visual inspection of diagnosis will not work. You can remove the stem and secured in a vise crank gear key, but it can be understood by heavy wear, in most cases will only dismantling of the barrel for the diagnosis.

Advice what to do in such a case,. If you can not remove a suitable part or replace, the vote barrel wear. Here's how, insert a new drill and to move from side to side, if a large gap is better to replace the barrel full.

It is worth noting, that the cause of the drill scroll when drilling with impact can be:

- bearing wear promvala;

- gear near the drunken bearing can be lapped up.

For sale if you search, you can buy a gearbox assembly to the punch and the cost of it is about 2000 rub.

Reliability some sellers doubt, but when you consider that it is often taken from the spare analogues which instruments are traded on such Avito. how to distinguish a fake punch the original.

For example, many Chinese counterparts hammers Makita. EXAMPLE perforator network FAVOURITE RH 950 and the cost of it in the aisle 3000 rub. that profitable to sell for parts.

Change details on the healthy and ready to collect. For more information on lubrication and assembly punch.

Read if problems with the electrical part of the perforator.

Video fast disassembling the gun Makita