- Design features bolgarok Hitachi

- Repair tool grinders Hitachi

- Faults Hitachi grinder for electrical parts

- Check motor

- Mechanical faults grinder Hitachi

- Repair gear grinders Hitachi

- Structure grinder Hitachi G13SR3 gearbox to drive 125

- Removing the driven gear shaft with gear grinders Hitachi disk to 125

- How to remove the pinion gear from the shaft grinders Hitachi rotor disk 125

- Replacing bevel gears in a Hitachi grinder

- Structure grinder Hitachi G23SCY gearbox to drive 230

- Removing the driven gear shaft with gear grinders Hitachi disk to 230

- Rules lubrication gear bolgarok Hitachi

- Video Repairs bolgarok Hitachi

Hitachi grinders are very popular among Russian builders. There are two reasons: high reliability and no fakes. Besides, the Japanese brand, based in 1910 year affordable price, a lot of innovation, high reliability.

Grinders (Bulgarian) Hitachi's are available in several varieties, depending on the power.

The purpose of this article, offer repair methods bolgarok Hitachi with their hands. Overhaul USM Hitachi, usually, Warranty is performed in service centers. But reading the proposed instruction, you can easily perform repair Hitachi grinder.

Design features bolgarok Hitachi

Even in appearance, you can immediately tell, that before you Bulgarian Hitachi. Upper plastic housing Hitachi LBM is composed of two parts of different colors and has an original shape laths.

The external contours of the body parts of the Bulgarian, special bright green and black, additional handle with mandatory labeling model, inscription bright white - are the main differences between the appearance of the Bulgarian Hitachi.

Under the Hitachi brand manufactures several models of Bulgarians. We select the most popular: G13SE2, G13SR3, G23SEY, G23sriu.

The figures in the designation indicate the maximum diameter of the applicable cut-off wheel.

Hitachi grinder, indicated under 13 have power to 1000 W. Grinders with numbers 13 designed to perform small works with a circle 125.

We Bulgarians with numbers 23 more power 1000 W. Bulgarians have labeled 23 used wheels 230 and may be performed more complex work.

Design feature bolgarok Hitachi is available to protect against overheating and improved cooling system.

All Hitachi grinder equipped with an additional handle.

Structurally, the Bulgarian family Hitachi from each other do not differ. Although minor changes may occur.

Repair tool grinders Hitachi

Hitachi grinder to repair is not possible without tools. You should prepare a set of screwdrivers, Control of short-circuited turns in the winding device, tester, passatiži, wrench. Can not do without improvised devices, if you want to repair their own hands Hitachi grinder.

Good, if you have a screw gun and interchangeable nozzle-screwdriver, properly fitted on the splines to unscrew the screws.

Of the appliances you need: bearing puller, press, vise, nastavki soft metal.

Strippers need for removing gears and bearings. The grip is convenient to clamp the individual nodes grinders. Spanner to spin the pinion fixing nut.

When the repair can not do without lubricants, wash, paints.

Need for cleaning rags or pieces pure material.

Do not forget about proper workplace equipment. It should be well lit..

All faults Hitachi grinder can be divided into two types: failure of electrical and mechanical problems.

Faults Hitachi grinder for electrical parts

Hitachi grinder suffer failure of breakers, carbon brushes, broken conductor stator windings.

Like all electric tools, appearance good electrical parts largely depends on the state of the carbon brushes. In Hitachi grinder installed carbon brushes with embedded device, popularly called "shot". The task of such a device, preventing inclusion Hitachi bolgarok at high carbon brushes wear.

The weak point in the design of the electrical part is bolgarok Hitachi place feeder cable. At this point most often occurs breakage, izlom, oholenye cable.

Check motor

Malfunctioning of the Bulgarian indicates several points:

- The rotation of the working member in jerks;

- Fall speed and power angle grinders Hitachi;

- Spontaneous set speed;

- Strong heating of the stator housing;

- The emergence of large sparks in the collector region;

- Burning smell, smoke.

The fall of power capacity due to breakage or short-circuit the rotor windings.

Repair of the rotor

Hitachi grinder rotor repair is no different from any repair rotor grinders. Not every consumer will be able to eliminate this type of fault. For this we need to have not only special devices, but also skills winder. It is preferable to send the failed rotor to specialized service centers.

But fans get to the truth we suggest reading the algorithm rotor rewind.

But fans get to the truth we suggest reading the algorithm rotor rewind.

On failure of the rotor indicates the occurrence of burning in the collector region. Usually, burn slats, there is a dark coating on the winding wires.

The rotor should be removed from the housing:

- Remove the carbon brushes;

- Remove the gear cover;

- Unscrew the nut on the pinion;

- Pull the rotor from the gear housing;

- Pull the rotor from the stator housing.

If there is IR-2 device, you can, without disassembling the rotor, measure the presence of short-circuit coils or open coils.

Disassembly of the failed rotor begin to dismantle from the armature rotor shaft bearing, impeller. Bearings and impeller is recommended to take a special stripper, to avoid damaging parts. If the collector is damaged and can not be restored, it must also be dismantled by means of a stripper. Pre Unsolder ends of the windings, soldered to the commutator bars. It remains to remove the burnt winding. Hacksaw cut the winding end, count the number of turns in the multiple grooves, Sketch the winding direction, estimate the percentage fill of the armature core slots. When micrometer help measure the diameter of wire. These data you will need, if you decide to reel anchor Hitachi grinder with his own hands.

For other consumers recommend to purchase the new rotor in service centers or online stores.

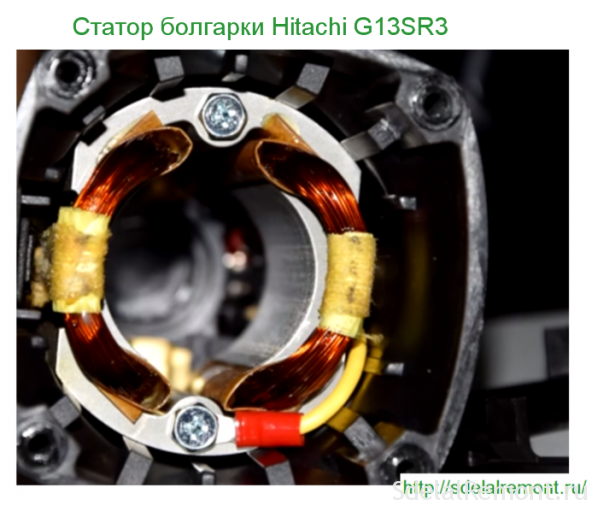

stator Repair

On the failure of the stator usually indicates significant overheating of the Bulgarian housing and spontaneous set speed, unmanageable. The fault can be determined, pulled out of the stator housing:

- Disconnect the gear housing and the stator housing, Remove the four screws;

- Pull out the gearbox with the rotor from the stator housing;

- Remove the plastic protecting the stator;

- Remove the two screws fastening the stator and remove it.

stator breakage is readily determined by a tester. But interturn short circuit is best measured by an IR-2 or oscilloscope. stator Repair Hitachi grinder own hands can be performed at home. But you have to have certain skills.

The failed first stator understands:

- Exempt carve contacts;

- On one end of the winding core is cut hacksaw;

- Is a number of stacked turns of wire, winding direction, the percentage of filling slots;

- Measure the diameter of the wire by means of a micrometer;

- Trimmed core of sludge trace, drops of molten copper wire.

Manufacturing of the stator is described in detail on our website. For those wishing to not be difficult to do the job.

A few tips when winding:

- Use of such a wire diameter, which was used in the stator;

- If the amount of the stator slots allows, preferable to use a larger cross section wire, but do not overdo it;

- Try to stack tightly wound coils at, controlling coil form;

- Closely linked coil mounting thread or cord;

- Wound stator winding is required to saturate the paint or varnish, using impregnation alternating voltage through LATR;

- At the end of the winding, clean middle of the stator core of the paint traces, varnish.

Repair of electric grinders Hitachi control circuits

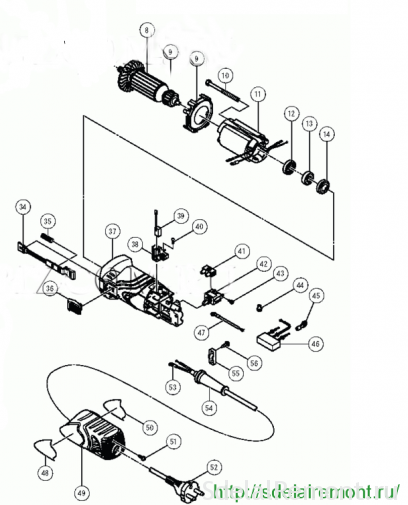

Electric power control circuit are simple structure. Perform the task of smooth running tools, rotation control frequency, enable or disable the tool. The structure of the switch control circuit includes, speed control, electric motor, carbon brushes, power cable and switching elements. Consider operation Hitachi electric grinder portion on the example of two patterns: Hitachi G13SB3 и Hitachi G23SCY.

Schematic diagram grinder Hitachi G13SB3 LBM 125

Power is supplied via the cable poz.52 terminals poz.53, is connected to the switch poz.42. At the entrance to the housing Bulgarian cable fixing clip poz.55. To switch connects suppressor poz.46 and wires to the carbon brushes poz.39. In Hitachi grinder carbon brushes used with auto. Carbon brush size in grinder Hitachi G13SR3 6.5 × 7.5 mm. Carbon brushes installed in the brush holder poz.38. Turning Hitachi grinder occurs by moving the switch button poz.36.

The most common failure in Hitachi grinder happen in case of failure of the supply cable to the login site, wear carbon brushes poz.39, failure in the switch poz.42.

Eliminated this kind of malfunction replacement of defective parts or pieces of wire.

Mechanical faults grinder Hitachi

In Hitachi grinder gearbox reliability admired. But it is at the correct operating.

When overheating or intermittent jamming of the tool, If dust, untimely replacement of carbon brushes, no Bulgarian would not last long.

Much driven gear in a Hitachi grinder with the disc to 125 mm is attached by means of key connection. Bulgarians have to drive to 230 mm pinion pressed onto the spindle shaft. Small pinion gear in any design Hitachi grinder is keyed and fixed nut.

Repair gear grinders Hitachi

Reducer Hitachi grinder manufactured with high precision. The LBM is practically not felt the beat of teeth gear wheels. Wear special gear affected by improper use. Consider a repair gearboxes Hitachi angle grinders two models: Hitachi G13SR3 и Hitachi G23SCY.

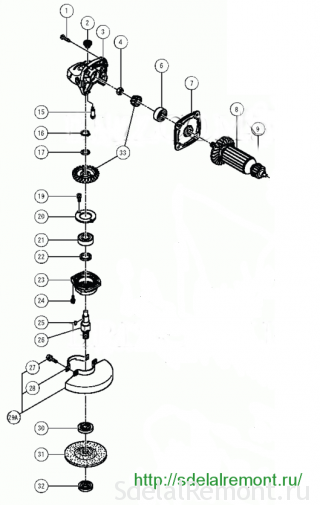

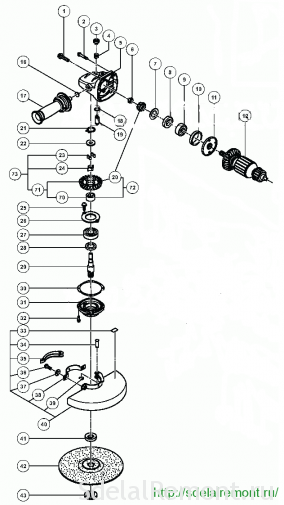

Structure grinder Hitachi G13SR3 gearbox to drive 125

The grinder with a disc diameter of up to 125 mm poz.33 driven gear mounted on the spindle shaft at 26 by means of key connection poz.25. manufacturing accuracy groove connection prevents the formation of play on the shaft of the driven gear. The presence or absence of backlash can be determined by turning in different directions of the spindle shaft. When there is a large clearance must be replaced simultaneously both gear, because they are made in pairs.

Removing the driven gear shaft with gear grinders Hitachi disk to 125

Understands shaft driven gear in the following sequence:

- twist 4(four) M4 screw × 12 poz.24;

- Remove cover poz.23 shaft;

- Poz.15 dismantled circlip ring and shaft poz.17;

- The shaft is extruded (knocked out) from cover, which is mounted bearing poz.21. Bearing Type 6021DD;

- Poz.33 driven gear is removed from the shaft by a simple tap on the shaft;

- Removed key poz.25

To get a bearing poz.21, unscrew 2 M4 screw × 10 poz.19, Bearing cap fixing poz.20. The grinder Hitachi G13SR3 used three types of bearings: 628 - mounted on a spindle gear, 626 - mounted on the rotor side pinion gear, 6201 - mounted on the rotor by the collector.

How to remove the pinion gear from the shaft grinders Hitachi rotor disk 125

To remove the pinion gear poz.33, it is necessary to clamp the rotor position 8. The pinion is fixed nut M6 pos.4. With spanner nut unscrew, rotating counterclockwise. removing gear, remove the rotor from the gear housing.

Replacing bevel gears in a Hitachi grinder

In Hitachi grinder defective bevel gear pair change. To replace the drive gear tooth wear, licking, destruction of several teeth.

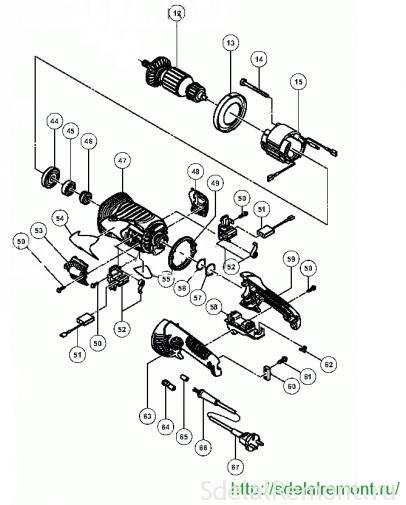

Structure grinder Hitachi G23SCY gearbox to drive 230

Reducer bolgarok disk to 230 mm is considerably more powerful. The design reducer 230 poz.24 applied clutch and damper poz.23. This design fulfills the role of cohesion, preventing shock when working drive biting his or emergency stop. Coupling enables smooth start grinders.

Removing the driven gear shaft with gear grinders Hitachi disk to 230

To dismantle the pinion gear to the disc 230 should be used, making, that no restoration work is not possible.

Disassembly of the driven gear is not different from analogous grinder assembly disassembling the disc to 125 mm. The only difference, in Bulgarian 230 gear poz.20 pressed onto the shaft poz.29. Remove from the shaft gear is better with the help of the press, but also the means at hand fit. for example, vise. The shaft is mounted in the bearing poz.27. Bearing Type 6302DD.

The Hitachi G23SCY grinder used three types of bearings: 6302DD - mounted on a spindle gear, 6301DD - mounted on the rotor side pinion gear, 6000VV - mounted on the rotor by the collector.

Rules lubrication gear bolgarok Hitachi

According to the grease in the gear unit can determine the percentage of wear of bevel gears. The darker the grease, the more in it traces of metal shavings, the greater the likelihood of increasing the percentage of gear wear. The percent wear reduction gear gears can be easily determined by the contact spot.

To remove the old grease use a special flushing fluid. To carefully remove all the old grease, recommended warm up gear housing with a hair dryer to a conversion to a liquid lubricant.

new grease superimposed in the gear housing in the amount of, less than half the volume of the housing. For the lubrication of gear manufacturers to produce their own lubrication. But Russian producers have learned to do lubrication, not inferior in quality to foreign, but the price is considerably less than the.

Conclusion:

- the reliability of Hitachi bolgarok provided technological and organizational measures;

- Hitachi grinder difficult to forge;

- in Hitachi grinder implemented the basic principle, The best ratio of price and quality;

- extend the work of the Bulgarian can timely change of the carbon brushes, grease replacement, sparing modes.

Video Repairs bolgarok Hitachi