Before you mount the flooring need to align all the floors in the apartment or room. For floor screed mainly used cement-sand solution. competently and accurately is necessary to save the budget to calculate the required amount of materials for a future solution to the floor screed. The calculation can be made using the online calculator for calculating floor screed.

The values given in meters, pay attention to the thickness. Specify in this format (0.00 m)

An example of calculating the number of necessary materials.

To calculate the required volume of solution use the formula:

S × h = V

Where,

- S - area of the room;

- H - height of the required tie layer;

- V - the volume of solution needed.

As above formula, we can calculate the required amount of dry mixture. The important points in calculating the required volume of solution is the fact, the volume of cement solution, sand and water is less than the total amount of all ingredients. So from one kilogram of the cement-sand mixture, after addition of water is obtained 0,7 kg. solution. Thus we obtain the required volume of solution formula:

The volume of the dry mixture / 0,7 The volume of solution required =

Cement and sand is sold in bags with pay per kilo, so we need to calculate the amount of ingredients in kilograms.

Assuming, what:

- one cubic meter of the cement-sand mixture weighs 1540 kg

- cement cube is 1300 kg substance

- in a cube of sand - 1625 kg

- The ratio of cement to sand in solution 1 to 3

- Can form separate ingredients generalized formula.

M c =( S × h /0,7) ×325

M P =( S × h /0,7) × 1220

Where,

- M p - the mass of cement needed;

- M n - mass of sand required;

- S - surface area;

- h - height of the layer.

Total. Using the online calculator floor screed, in practice, you can avoid additional costs and find out the amount of material.

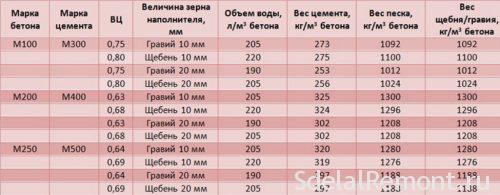

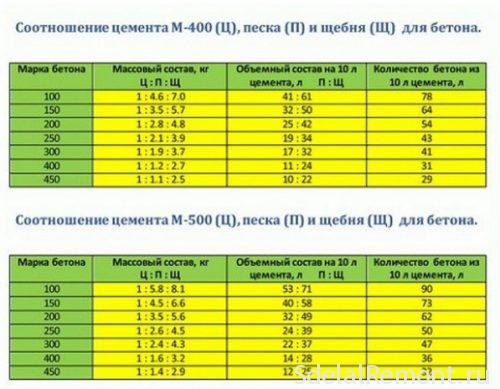

Table volume proportions for different grades of concrete

|

Concrete, mark |

The ratio of cement / sand / gravel |

|

|

cement M 400 |

cement M 500 |

|

|

100 |

1,0 : 4,0 : 6,0 |

1,0 : 5,2 : 7,0 |

|

150 |

1,0 : 3,1 : 5,0 |

1,0 : 4,0 : 5,8 |

|

200 |

1,0 : 2,4 : 4,1 |

1,0 : 3,1 : 4,8 |

|

250 |

1,0 : 1,8 : 3,3 |

1,0 : 2,4 : 3,9 |

|

300 |

1,0 :1,6 : 3,2 |

1,0 : 2,1 : 3,6 |

|

400 |

1,0 : 1,1 : 2,5 |

1,0 : 1,4 : 2,7 |

|

450 |

1,0 : 1,0 : 2,1 |

1,0 : 1,2 : 2,4 |

|

cement brand |

Marc solution |

The rate of application for the cement manufacturing 1m3 solution |

|

M400 |

M200 |

490 kg |

|

M500 |

M200 |

410 kg |

|

M400 |

M150 |

400 kg |

|

M500 |

M150 |

330 kg |