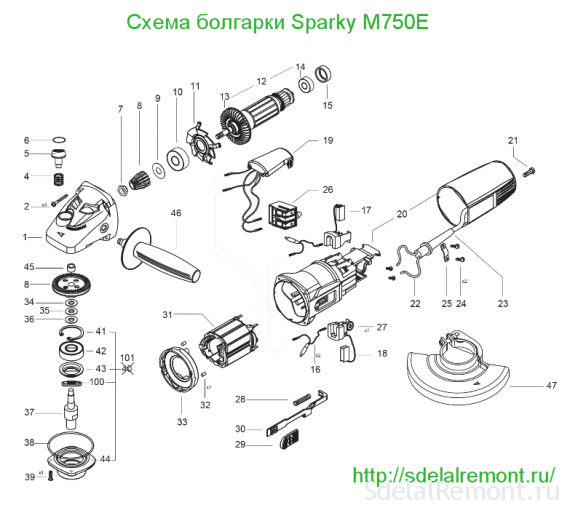

- Design features LBM Sparky

- Repair tool bolgarok Sparky

- Mechanical faults bolgarok Sparky

- repair gear

- How to change gears in the gearbox Sparky

- How to replace bearings in the gearbox

- Faults electrical grinder Sparky

- Repair the control circuit grinders Sparky

- Repair of the rotor

- How to replace bearings on the rotor grinders Sparky

- stator Repair

- Opening a Bulgarian Sparky

- The choice of lubricant and the procedure for its application into the gear grinders Sparky

- helpful hints.

- Video Repair Bulgarian Sparky

Russian consumer prefers Bulgarian Sparky not only because of the high operating convenience, but also ease of repair grinders Sparky, favorable price-performance ratio, presence of the frequency control device turns, anti-vibration handle, original guard.

Sparky firm grinders are available in three classes: small, medium and large. The class is determined by the size. In a small class is available 15(fifteen) models, whose weight ranges from 1,2 kg 2,4 kg. The middle class is represented by three models, by weight which is within the range of 2.5 ... 3.3 kg. In a large class produced 10(ten) models, reaches weight 6,3 kg. Recognition bolgarok Sparky gives a striking appearance: purple body, bright red or silver color of the gear housing.

Design features LBM Sparky

The special features of Bulgarians are Sparky:

- Multi-selector, It has the option of blocking the spontaneous start grinders;

- The body is made with double insulation;

- There the starter, setting and maintaining a constant frequency of rotation of the rotor;

- The construction of the brush holder does not allow trapped dust and wedged carbon brushes;

- The grinder is used to automatically turn off the carbon brushes;

- Complete with anti-vibration handle;

- Application of a protective casing with quick installation and removal;

- Gear housing made of durable, lightweight magnesium alloy;

- Rational system of ventilation holes, improves the cooling process.

Repair tool bolgarok Sparky

To perform high quality repair grinders Sparky any modification, without quality and the right tool can not do. The tool will be charged, any special requirements.

Because Sparky grinder used bearings, for their removal is advisable to use strippers. Russian craftsman can do without strippers, but the quality of repair is not run.

Repair angle grinding machines Sparky is divided into electrical and mechanical repair parts.

For repair electrical parts need Tester. If you have the opportunity to buy or rent a device for determining the short-circuited turns, we recommend that you use a simple IR probe 2. Such a device allows finding breakage or short circuit of windings of electrical parts without dismantling. It is indispensable when the rotor repairs, stator grinder.

Prepare screwdrivers in various sizes. Can not do without wrenches.

Of the supporting materials will need lubricant for gearboxes and bearings, rags or cleaning material, cleaning fluid. At home, it is recommended to use a mixture of kerosene and gasoline.

If you plan to repair the rotor or stator of angle grinders, for the impregnation of windings need to varnish or paint.

Repairs grinders with their hands must be performed on a prepared, well-lit workplace.

Mechanical faults bolgarok Sparky

All faults in Bulgarian are divided into mechanical and electrical.

Mechanical failure are:

- The destruction of the gearbox, failure of gears;

- Jamming or destruction of bearings;

- The destruction of the gearbox housing grinders.

repair gear

Reducer Sparky grinder represents a gear pair, enclosed in a robust housing. On the spindle driven gear attached a different tool, allowing to carry out the work with metal, stone, wood.

In most cases, breakage of the gearbox associated with the failure of one of the gears. At the gear tooth chipped off or licked, destroyed the basic needle bearing. Besides, fails bearing bush or needle bearing.

The design of the gear grinder Sparky different models differs slightly depending on the power.

Driven gear in gear grinders Sparky fastened in two ways: pressed onto or use the key connection. Key connection is most commonly used in low-power grinder Sparky. As key is used the small-diameter ball.

Repair gear grinders Sparky provides not only the replacement of the failed parts, but the lubricant change.

The grinder capacity over 1000 W driven gear is pressed onto the spindle shaft and is removed only with the help of the press. But at a certain skill This procedure can be performed without the use of media. We need only remember, care and precision - the main factors of success in carrying out this work.

Remove the driven gear in the cellar. It is necessary to promote a housing cover screws, pull out the cover with integrated bearing and spindle. Pull out the spindle shaft bearing. If the driven gear is attached with tabs, the, before gear dismantled, it is necessary to remove the lock ring. In some low-power model is used as a key small-diameter ball.

Removing the retaining ring, can be neatly dismantled the key and release the driven gear. Replacing the gear produced in excess cent tooth wear. And it is determined only by the contact patch area of the pair of teeth. Contact patch is the main characteristic of the gear pair operability.

Pinion gear in Bulgarian Sparky shoot even easier. All Bulgarian Sparky drive gears are mounted on the rotor shaft with the key and clamped nut with right-hand thread.

To dismantle the pinion gear unit must be removed from the stator housing. Before you get the rotor, carefully remove the carbon brushes, impeding recovery rotor. Carbon brushes grinder Sparky low power control can be, removing the cover of the stator housing. To do this, unscrew the screw in the side of the case and pull the handle cover.

At high power grinder Sparky carbon brushes can be removed, without disassembling the handle.

How to change gears in the gearbox Sparky

To remove the drive gear, necessary to release the rotor clamp in suits, pre paving protective pad. Gasket choose from a soft material, not to damage the rotor housing.

Using a spanner S = 12 unscrew the nut, fixing the pinion gear on the rotor, turning the key anticlockwise. If you unscrew the nut on the first try does not work, pour liquid into the threaded joint HP-40. Dove liquid influence for some time, try again loosen the fixing nut. Usually, it turns out.

When the nut is released, You can pull the rotor shaft of the gearbox housing. The pinion gear is fixed to the rotor shaft by means of dowel.

Just remove the lock ring, if so provided in the design, pull out the key, just as the gear is removed from the rotor shaft.

Remember the golden rule. Gears in the gearbox are always changing pairs.

by the way, a grinder Sparky low and high power is provided an opportunity to backlash between a gear in the gearbox by means of special shims.

by the way, a grinder Sparky low and high power is provided an opportunity to backlash between a gear in the gearbox by means of special shims.

How to replace bearings in the gearbox

One of the gearbox fault in Sparky Bulgarian manifested by the backlash of the spindle shaft. This can happen in case of failure of the bearing shaft, and supporting needle bearing. The emergence of backlash indicates the destruction of the needle bearing in the gearbox housing. Of particular difficulty is the extraction of the needle bearing outer cage of the socket in the gear housing.

The easiest way, machine using suitable diameter and tap screwdriver to remove the clip from the housing. Hold the tap in the cartridge screwdriver and try to screw the tap in the bearing race. When the tap reaches the bottom of the nest, it will begin to lift cage.

Since the spindle shaft bearings are removed by using a stripper or folk remedies.

The low power grinder to Sparky 1000 W type needle bearing applicable NK0709. In some low-power models apply mednografitovye sleeve.

Bulgarians spindle shaft to Sparky 1000 W is rotated in a bearing type 6300-2RS.

The gearboxes Sparky Bulgarians over 1000 W used more powerful bearings: basic needle-type NK-1212, sliding type bearing 6206-2RS. Sleeves in heavy-duty grinder is not used.

Faults electrical grinder Sparky

For proper operation of the Bulgarian Sparky uptime may be several thousand hours.

The basic rules of fault-free operation of power tools:

- Timely replacement of carbon brushes;

- Regular replacement of the lubricant;

- Preventing the use of the tool at high loads;

- Prevention of the tool overheat;

- Intended use tool.

Repair the control circuit grinders Sparky

bolgarok various power control circuits have their own characteristics. The grinder capacity of less than 1000 Watt switches used ARV-2114 Defond, an electronic device for controlling the rotational speed of the spindle.

Photos scheme of control circuits

the control circuit bolgarok Sparky more 1000 W type switches are equipped KD10, capacitor, carbon brushes with contactor, members of the brush holder.

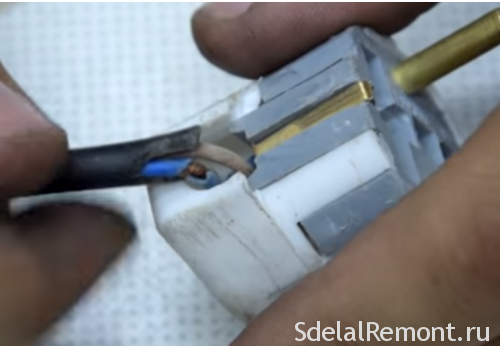

Most often grinder Sparky fail of electric parts due to breakage of the supply cable. This occurs in the areas of cable entry into the instrument and plug.

The second tool exit reason of the electrical part, wear or breakage of the carbon brushes. The carbon brushes must be changed, when worn brush length is not more 5 mm.

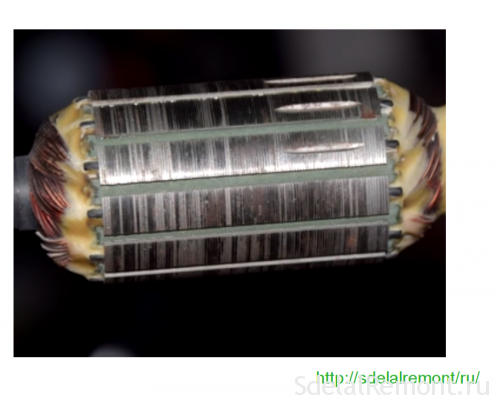

Repair of the rotor

The rotor grinders Sparky fails due to overloading and overheating, wear or untimely replacement of the carbon brushes, appearance of an open or short circuit windings, the destruction of the collector or the destruction of the bearings, resulting in the rotor rubbing on the stator.

The rotor is a complex item, repair that without certain skills, skills and equip difficult. It is preferable to buy a new rotor or contact the workshop, if the first time you see the rotor. If you want to repair the rotor grinders with their hands, talk to content, already posted on the website. However, breakage of the rotor entails not only a failure of its electrical. Most often the reason for its output becomes destruction or wedging bearings. Sparky on the rotors Bulgarians set two bearings. One side of the fan, and the second by the collector.

How to replace bearings on the rotor grinders Sparky

On grinder with a capacity of more than 1000 W on the rotor bearings are mounted following.

Bearing near 6000-2ZP63LDS18 type collector.

End bearing type fan 6202 ZTNHP63LDS18.

Bulgarian power up 1000 W equipped with such bearings.

Bearing near 6262ZP6E LDS18 SKF type collector

End bearing type fan 6092ZP63LDS18.

On the failure of the bearing points to the difficulty of his scroll, jamming, color change to dark, Bearing Race destruction. Removed bearings using pullers. Operation is no particular difficulty and can be performed by any user.

stator Repair

stator design in Bulgarian Sparky is no different from other Bulgarians stators. Repair is to identify the causes of failure and rewinding. To determine an open or short circuit the stator windings is preferable to use the tester and determining short circuit indicator.

Fast stator rotor repairs much simpler and can be performed at home.

Stator Repair Algorithm simple and more than once led to our site. To manually wound stator, must not only be able to correctly calculate the number of turns, the order of winding, but also be able to properly impregnate the winding varnish.

Opening a Bulgarian Sparky

Regardless of the power of Bulgarians family Sparky order of disassembly virtually identical.

Disassembly begins with the dismantling of the carbon brushes. They are easy to get, when you remove the housing cover or protection for the brush holders.

The thing is, that for extracting the rotor from the stator housing carbon brushes prevent the rotor extraction, erasing of the commutator bars.

In the next stage disconnects the gearbox housing and the stator housing. It is only necessary to unscrew four screws, holding the gear housing and the stator housing.

To disassemble the gear housing cover must be removed, removing the four screws. The gear cover mounted shaft assembly driven gear. Disassembly of shaft assembly driven gear, we have already discussed.

Electrical parts even easier to disassemble, because the number of parts in its structure even less.

The carbon brushes mounted in brush holders and fixed by special clamping springs. Pulling brushes during repair, memorize the position and direction of their installation. Brushes wear unevenly. And wear of the brushes affects the rotor rotation angle.

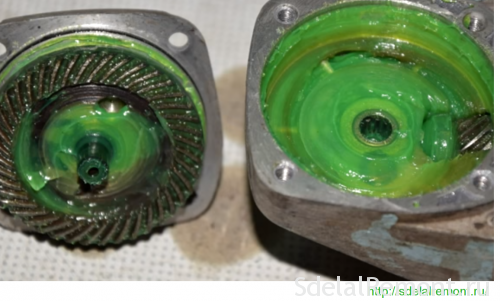

The choice of lubricant and the procedure for its application into the gear grinders Sparky

Manufacturers Bulgarian Sparky recommended for the lubrication of tools used grease Liver T-0-1,00 kg. But may be used and specially designed for the lubrication of gearboxes bolgarok domestic lubricants. At present, lubricants choice is wide enough for Bulgarians.

Besides, quality lubricant for gear grinders can be made and at home.

It is only necessary to base grease, which is very well adhere to the metal surfaces and  hardly comes off at high speeds. Scientifically, based lubricants should have increased adhesion.

hardly comes off at high speeds. Scientifically, based lubricants should have increased adhesion.

As a basis, satisfying the requirements, grease fits best for articulated vehicles connections. Take the CV joint grease-4 as a basis.

Was added thereto using a syringe grease TAD-17 and stir until the consistency of thick cream. Interfere with better lubrication using a drill, armed homemade mixer.

The gear housing should lay much grease, how much is put in half the volume of the reducer.

Grease is applied after careful removal of the old grease. For a thorough and complete removal of the old grease is recommended to use a hairdryer, through which warmed the old grease and follows easily from all inaccessible cavities

helpful hints.

- After 700 hours of work, check the state of the carbon brushes;

- With any heating Bulgarian housing make technical maintenance tools;

- It is better to change the carbon brushes more often, than to buy a new grinder;

- Check the condition of the lubricant and are replacing it with a significant color change;

- To enable a reliable low power grinder Sparky periodically lubricate lever incorporating silicone grease button;

- Listen to the sounds of gear (serviceable machine does not give off loud noises);

- Frequently check the clearance between the gears. An increase use special shims. (The design bolgarok family of three Sparky);

- Do not skimp on the grease or carbon brushes, the more often you change the lubricant and install new brush, the longer it will serve you;

- If you design your family Sparky grinder in the gearbox as a bearing sleeve is used mednografitovaya, replace it with an appropriate size needle bearing.

If you decide to purchase a grinder family Sparky, you will get a quality tool, which will bring you joy at work, but will create some problems for the repair

Video Repair Bulgarian Sparky