- Features perforator Hitachi

- The procedure for disassembling the gun Hitachi

- Dismantling the keyless chuck type SDS-plus

- Disassembly of the three-position mode switch

- Dismantling housing

- Disassembly of the mechanical block

- Dismantling countershaft

- Dismantling of the striking mechanism barrel

- Dismantling the hammer parts

- What are the types of bearings used in the perforator Hitachi DH24PC3 and their Russian counterparts

- Disassembly electrical perforator Hitachi

- Disconnecting the rotor from the mechanical block

- disassembly of the stator

- Dismantling of the control circuits

- Video Repairs perforator Hitachi

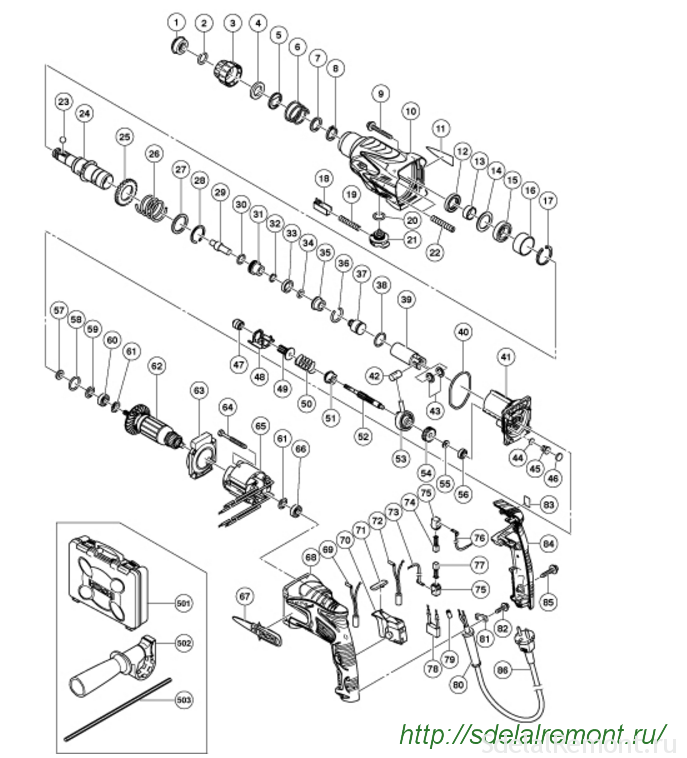

Dismantling perforator Hitachi DH24PC3 required in the case, when you want to repair the instrument with his own hands. But for that you need not only a detailed diagram of the perforator Hitachi, but also instructions for its dismantling, lubrication and assembly.

Dismantling Hitachi perforator does not require special skills from the user, if he strictly follows the recommendations proposed for disassembly instructions.

Features perforator Hitachi

Tri-mode perforator Hitschi DH24PC3 produced by Japanese manufacturers. The power of the gun is 800 W.

At Punch provides stepless adjustment of speed 0 ... 1150 rev / min at a controlled frequency 0 ... 4600 strokes / min.

The impact force is 3,2 J..

Weight perforator is 2,4 kg.

Perforator Hitachi DH24PC3 equipped with a keyless chuck type SDS-plus. Hitachi Hammers are designed for drilling holes up to 24 mm in the concrete in the hole and blow mode.

The chipping hammer mode helps remove tile, Stroebe grooves for cable laying, pipe communication.

The hammer drill mode allows you to drill holes in wood to 32 mm, screw the screws using additional attachments.

The punch is provided reinstalling the front handle at any angle, which creates additional convenience in tight spaces.

The procedure for disassembling the gun Hitachi

To repair the perforator Hitachi DH24PC3, it is necessary to perform a technological operation, as the disassembly tool.

Getting disassembly, Prepare the workplace, pick up tools, related materials, documentation.

The smooth surface is suitable as a workplace, the laid paper or a net material. The place should be illuminated uniformly and adequately.

From the Tools Prepare pliers, screwdriver, passatiži, Cordless, vise.

As the documentation you will need to disassemble the scheme, lubrication diagram and the accompanying guide.

Dismantling perforator Hitachi DH24PC3 begins with the dismantling of the keyless chuck.

Dismantling the keyless chuck type SDS-plus

To disassemble the puncher, it is necessary to remove the keyless chuck:

- • Using a screwdriver, remove the protective rubber bellow pos.1;

- • Pull circlip pos.2;

- • Carefully remove the cover pos.3;

- • Push the steel ring position 4 and the guide washer pos.5, Remove the locking ball poz.21;

- • Remove the steel ring, guide washer, conical spring pos.6;

- • It remains to get the puck position 7 and the locking ring 8 is launched.

Keyless chuck dismantled.

Disassembly of the three-position mode switch

Proceed to dismantle poz.20A mode switch.

Pre-set the mode switch to the "Beat". By clicking poz.17, Turn the knob counter-clockwise on the angle 15º, and pull it out of engagement.

Video Bork perforator Hitachi DH24PS3

In the next step in the dismantling of the gun Hitachi DH24PS3 housing should be removed label-label. It is located on the left side of the body, when viewed from the side of the handle.

He removed with a screwdriver by poddevaniya.

Dismantling housing

Proceed to disassemble the housing.

Install vertical casing perforator, propped it on the handle. in aid screwdriver or screwdriver to unscrew 4 screw pos.9. To remove the cover of the mechanical block, should press the lever in the opening shot mode switch and pull the cover up.

The lid of the mechanical block mounted aluminum intermediate body, and wherein the hammer is pressed trunk. The housing of the mechanical unit consists of two parts: Internal aluminum and plastic outer.

Disassembly of the mechanical block

To disassemble the mechanical block must perform several separate operations.

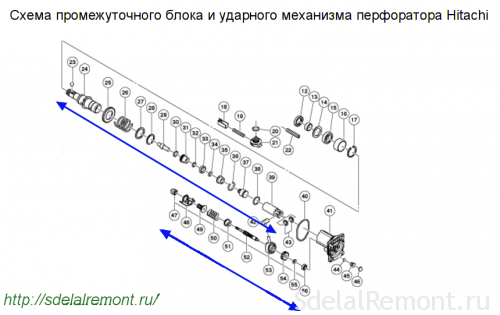

The first stage involves dismounting countershaft, then removed the striking mechanism barrel and dismantled its individual components.

Dismantling countershaft

Poz.47 intermediate shaft is inserted into the inner housing poz.39. For removing it enough to pull out the shaft of the inner body.

On the intermediate shaft assembled several details, the most important of which is drunk bearing and mode switch.

The operating principle of a simple punch. The torque is transmitted from the helical gear reducer (not shown) a helical gear position 1, mounted on the intermediate shaft.

Then the torque is transmitted via a small spur gear of the intermediate shaft to a large spur gear, mounted on the hammer barrel shaft. Simultaneously, by means of bearing drunk pos.2 reciprocating impulse is transmitted to the hammer piston. pos.4 mode switch using pos.3 coupling enables or disables the transmission of shock pulse or rotational movement.

To disassemble the intermediate shaft must be consistently removed helical gear, Rolling bearing with the clutch, mode switch.

Dismantling of the striking mechanism barrel

stem impactor shaft is pressed into the plastic cover of the mechanical block. To get a tree trunk poz.24, it is necessary to remove the retaining ring 8 is launched outside of the mechanical unit cover. When the locking ring will be removed, you can begin to impact mechanism pressing out of the barrel by means of a press or devices.

It is not desirable to get the trunk percussion, so as not to damage the plastic casing perforator.

If there is no media, then fit a large bench screw. But they need to make a simple adaptation of a hard material, eg, wood.

New barrel to punch Hitachi DH24PC3 sold in assembled form. Although you can buy a barrel, but Chinese production.

Dismantling the hammer parts

To create an impact impulse in the trunk of the hammer piston is inserted into the sleeve punch poz.39, in which, in turn, poz.29 inserted striker and a striker mechanism shock poz.37.

In the tail portion of the sleeve piston the piston pin is secured, which is inserted into the opening rod rolling bearing poz.53, Popularly known as "drunk bearing".

Remember! When repairing all rubber components are replaced on a mandatory basis.

What are the types of bearings used in the perforator Hitachi DH24PC3 and their Russian counterparts

The perforator Hitachi DH24PC3 applied following bearings made in Japan:

- • Poz.15 bearing 37 mm, article 6904DD, size 20x37x9, Russian analogue 1000904;

- • Poz.56 bearing 19 mm, item 626VVM, dimensions 6x19x6, Russian analogue 26;

- • Poz.60 bearing 22 mm, item 608DDM, dimensions 8x22x7, Russian analogue 80018;

- • Poz.66 bearing 22 mm, item 608VVM, dimensions 8x22x7, Russian analogue 60018;

Now we can proceed to disassembly electrical perforator Hitachi DH24PC3.

Disassembly electrical perforator Hitachi

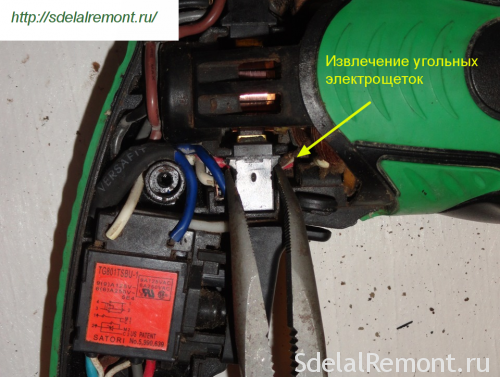

Disassemble electrical punch begins with the dismantling of the carbon brushes.

To get coal electro, it is necessary to reveal the gun handle, removing the cap screws with a screwdriver or a screwdriver.

Prying screwdriver latch, free carbon brushes poz.69, 72 using a pair of pliers.

Disconnecting the rotor from the mechanical block

Taking the right hand of the mechanical part, and to the left of the stator housing, pull them in different directions, pokachivaya. Poz.62 rotor out of the stator housing.

Now take the left hand of the rotor itself, and gently pull it out of engagement with the mechanical part of the perforator. The rotor is held in the mechanical part of the punch frictionally in helical gears.

disassembly of the stator

To remove the stator poz.65, it is necessary to remove the plastic cover and unscrew the screws poz.63 poz.64, holding the stator housing. Do not forget to disconnect the wires from the switch of the stator.

To remove the stator from the casing to take the left hand stator housing, and in the right hand mallet or a bar and tap the end of the housing. Each time tapped stator will slowly come out of the housing. Read, how to check the serviceability of the stator and rotor.

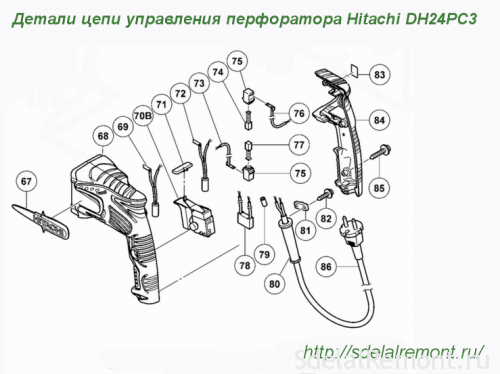

Dismantling of the control circuits

To remove the switch with speed control, you simply remove it from the body handles the gun Hitachi DH24PC3.

The punch used poz.70V pushbutton switch on 220 AT, type OLD331454 / 324536. The carbon brushes are kept in special poz.74 brush holders poz.75.

Video Repairs perforator Hitachi