- Mechanical faults Hammers Bosch

- Puncher ceases to peck, but drills

- Puncher stopped drilling, but hews

- Consider the options, in which the punch does not hollow, but drills

- Consider the options, hammer drills in which, but do not hammer

- Consider the options, in which the punch does not drill or hammer

- Common electrical problems Hammers Bosch 2-26

Nothing is eternal. And the most reliable Bosch rotary hammers begin to break down over time,. But any failure can be repaired with their own hands, if you have a detailed guide for repair works. Below we offer you a guide to detect faults in the Bosch rotary hammers and methods of their elimination.

The main reasons for the appearance of breakages are:

- sloppy work with the instrument;

- improper storage of the gun;

- heavy loads at work on the working bodies when chiselling or drilling;

- instrument overheating;

- continuous operation without interruption;

- delays in maintenance.

Conventionally, failure can be divided into mechanical and electrical.

Next, we consider the fault of their membership, dividing by the malfunction of mechanical and electrical.

Mechanical faults Hammers Bosch

When the mechanical fault in the instrument stranger unpleasant sound appears, enhanced sparks in the collector region, there is a smell of burning, unnecessarily heated tool, its capacity decreases depending on the duration of work and the impact on the material.

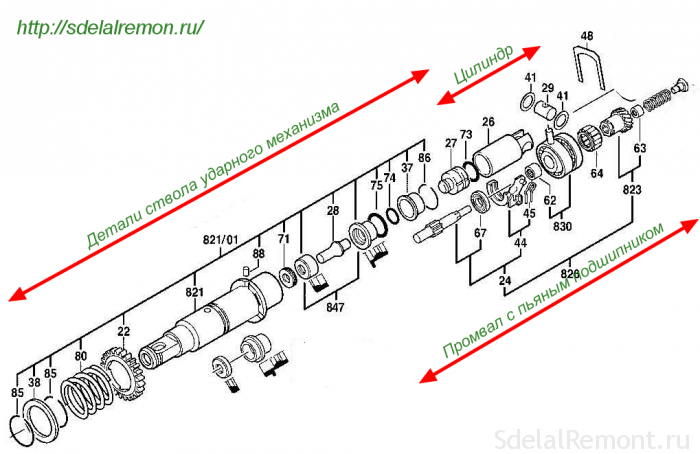

All faults, consider the diagram Hammers Bosch 2-26. Other models, such as Bosch 2-20, 2-24, construction differ countershaft, installing various drunken bearings.

Puncher ceases to peck, but drills

The puncher does not hollow under load or idle for the following reasons:

- striker worn rubber ring, hammer, piston;

- collapsed cage of the rolling bearing;

- collapsed cylinder, the firing pin striking mechanism barrel;

- cut the splines of the clutch, mounted on the intermediate shaft;

Puncher stopped drilling, but hews

Main reasons, in which the hammer drill, but do not drill, this:

- The strength of the conical spring, pressing the clutch;

- locking clip does not capture large gear shaft barrel;

- locking mechanism is not holding the instrument in the barrel;

- The puncher does not hammer or drill.

The main reasons, in which the punch is not hammer and drill, are:

- Cut small teeth on the rotor gear or large gear of the intermediate shaft;

- not working motor perforator;

- there is no power to the electric punch.

Now first things first

Consider the options, in which the punch does not hollow, but drills

Wear rubber rings on the striker, boyke, piston.

This cause appears gradual, at least wear rubber rings. First blow weakens, then all is lost.

The fault is eliminated by replacing said rubber rings new.

For any repair hammers, his hosts, must be replaced all the rubber products.

Collapsed cage of the rolling bearing (drunk bearing)

With the destruction of the bearing drunk poz.830 rotary motion of the intermediate shaft can not be transformed into translational movement of the cylinder in the impact mechanism.

Eliminated by the complete replacement of the rolling bearing.

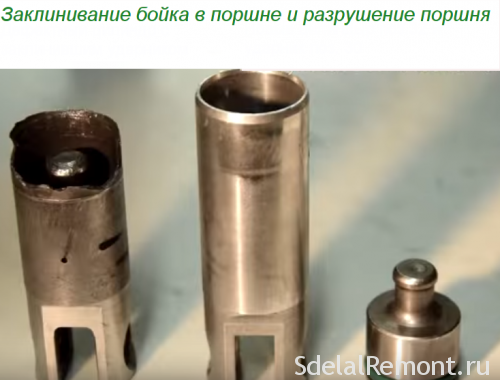

collapsed cylinder, drummer, peen hammer mechanism trunk

there are cases, When snack drummer in the cylinder at 26, which leads to the destruction of the cylinder and the inability to create an air pressure in the hammer barrel. And the second reason: disruption or failure of striker pos.28, resulting in a curvature part and the shock pulse transmission impossibility.

Breakage are eliminated complete replacement of defective parts.

Cut the slots poz.67 clutch clutch, mounted on the intermediate shaft

The fault is corrected clutch repair or its complete replacement.

In the production of repairs on the clutch zapilivaem crafted teeth. To correct this defect using a round needle file and drill. Coupling is clamped in the hand, and a drill with a suitable needle files straighten teeth profiles. Similarly, modify and slots on the intermediate shaft.

Consider the options, hammer drills in which, but do not hammer

Weakened the power of the conical spring, pressing the clutch

When poz.50 spring pressure force is reduced, slipping clutch on the intermediate shaft, without transmitting the rotation of the small spur gears on the large gear poz.22 trunk poz.821 shaft impactor. by the way, on different models of Bosch clutch arranged differently.

The locking clip does not capture large gear shaft barrel

Poz.22 large gear mounted on the barrel shaft pos.01 roller poz.88, pressed against the shoulder of the shaft and the conical spring poz.80 fixed circlip poz.85.

The reason may be weakening the efforts of the conical spring poz.80, destruction circlip poz.85, loss of the fixing roller poz.88.

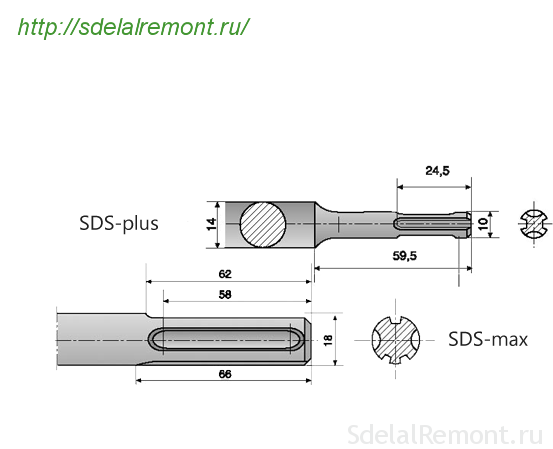

Not holding a drill tool fixing mechanism in the gun barrel

The Bosch rotary hammers are used two types of cartridges: SDS-plusи SDS-max. The difference in the design of the locking mechanism.

The reason for deterioration of the scanning antennae sleeve chuck, which makes it impossible to transmit the impact impulse working tool puncher.

Consider the options, in which the punch does not drill or hammer

Cut small teeth on the rotor pinion

Gears spinning occurs with shearing teeth on one of them, often at low.

When the tool jamming and improper operation of the clutch occurs deterioration or complete destruction of gear teeth on the shaft of the perforator and the intermediate shaft.

In this case, it is changing the rotor fully or large gear of the intermediate shaft.

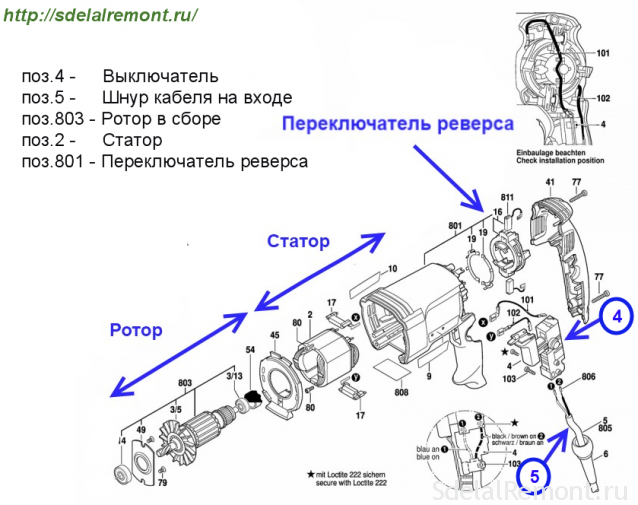

It does not work motor Punch

The reasons for not operating the motor can be:

- a short circuit in the rotor, stator;

- destruction of coal electrobrushes;

- weakening of the brush holder mount;

- burnout slats on the rotor manifold;

- breakage of the rotor or the stator windings.

Resolves the fault repair (Fast manual winding, replacement of the collector and Pin layout of the windings) or replacement of the rotor, stator, coal electrobrushes new.

The main part of the fault electrical perforator Bosch 2-26 supported by increasing sincerity in the reservoir area.

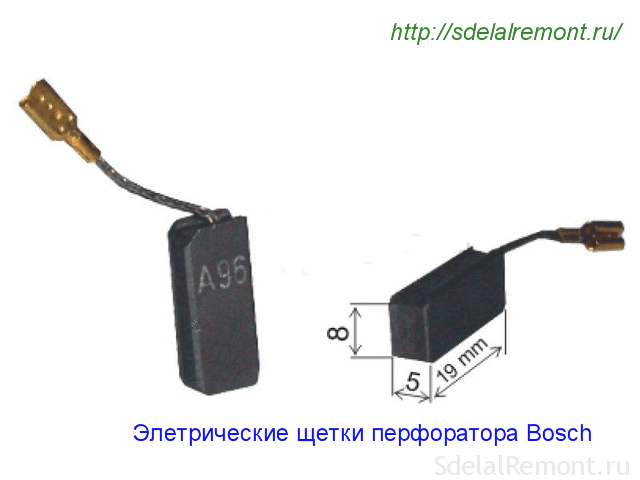

Electrobrushes serviceable length can not be less 8 mm. When replacing one brush, the second is to change automatically.

rotor winding or the stator can be rewound his hands alone at home.

No power to the motor perforator Bosch

The reason for this fault in the event of wire interruption, supplies power to the electric motor. Most often a disconnection occurs in the cable entry location in the punch. The wire should be replaced by a new or repaired. The fault can be determined using a tester. If there is no tester, the fault can be found with the use of phase and power screwdriver with neon lamp indicator. Connecting in turn the power wires, at the other end by means of a screwdriver neon determine the presence or absence of phase.

Not working power button punch. Determined to short-circuit tester.

Most often to failure of the perforator button causes a short circuit of the filter capacitor. It is best to replace with a new button.

Common electrical problems Hammers Bosch 2-26

Failure of the electrical part of the punch is accompanied by a burning smell, strong heating of the tool during operation, the emergence of large sparks in the vicinity of the perforator rotor collector, poor reverse switch actuation.

On the gun work affects the state of the carbon brushes, brush holders are secure and correct installation.

Burning smell appears during a short circuit of the stator or rotor windings.

Falling perforator power with increasing load characteristic at breakage in the rotor windings or the length of the small carbon brushes.

By the heating punch often leads interturn short circuit in the stator and the rotor.

Great sincerity in the reservoir area of the rotor caused by the inter-track circuit, or burn the commutator bars.

Violation of the reverse switch is due to the burning of his contacts.

But the main cause of all failures, untimely fulfillment of technical maintenance works and replacement of carbon brushes.

The carbon brushes need replacement after 70 hours or wear to 8 mm in length.

We have led the main cause Bosch hammers down.

maybe, we do not describe all the breaking hammers Bosch.

If you know of any other fault in rotary hammers Bosch 2-20, 2-24, 2-26, share with us.

I wish you success!

Video replacement raster sleeve chuck Bosch 2-26

Video replacement anchor Hammers Bosch 2-26