Our main protector against severe weather conditions is the roof, and in order, that it fully perform its function correctly it is necessary to select materials for the roof. As is well known, they are divided into many species, one of which is sheet metal roofing materials. It is about them and we'll talk.

Types of sheet materials

To begin, in general terms, we shall understand what sheets exist, then consider in more detail each of the species.

In total there are 7 species:

- Proflist

- metal

- composite tiles

- Wavy bitumen sheets

- Light-transmitting sheet

- Asbestotsimentnye (slate).

- Seam roof

And now, after that, as we learned all kinds, you must consider them in more detail. Learn about their properties, pros and cons.

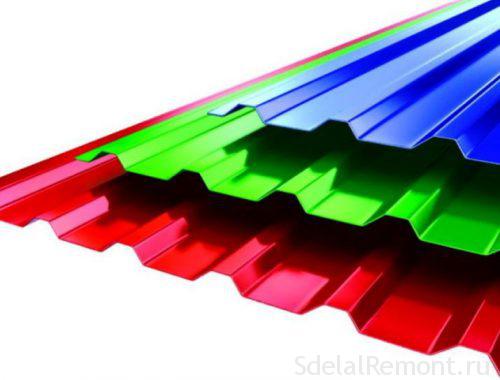

Decking

The first type of sheet material are flat metal sheets. Their use is possible only in cases, when the roof slope is not less than 12 degrees.

The material itself is fastened by means of special anchors to the base (accordingly requires everything lath. Sheets are made of galvanized steel, further covered with several layers of protective compositions, and can also be painted.

Submitted to several types of market:

- direct Prices.

- Polnistye.

- With a triangular profile.

- rectangular profile.

Are used in various fields such, ranging from houses and finishing with production sites. But the greatest popularity gained in the regeneration of the roof is of industrial buildings, as well as farm buildings.

dignity:

- Large operational period, that reaches 50 years old.

- Material fairly easily mounted, that allows you to perform all the work themselves, without the involvement of specialists.

- Also, there is a high level of strength.

- low cost.

disadvantages:

- The material is quite noisy, which requires an additional arrangement of soundproofing.

- It is also worth considering, that this metal, respectively, and it may need additional teploizorlyatsiya, when, if the roof is directly above the living quarters.

metal

This material is a one-piece sheet, surface pattern which simulates perfectly laid tiles. The use of such material, compared with conventional roof tiles significantly reduce labor costs for installation, It is considerably reduced as the number of stitches on the surface.

Sami sheets made from aluminum base, or galvanized metal. There is also the fact, that all parts of the sheet texture is absolutely identical and completely repeated.

And noted that, there is no single-sized sheets, because, depending on the situation, the customer can choose the desired size of the material. The width of the sheet generally is 1,1 m, while the length may vary from 40 centimeters to 8 m. Besides, Shingles itself easier 6 time, than its natural counterparts.

When laying the required slope is less 12 degrees. Fixing is carried out as, as in the case of Bent, with screws to a batten. Wherein, It does not require pre-drilling holes.

Sami sheets are overlapped on each other, wherein the possible laying on the old coating, without dismantling.

But it is worth noting a significant disadvantage, This noise flooring in the rain, snow or hail.

composite tiles

Material number similar to conventional metal tile, but they should not be confused, there are a number of significant differences.

The first composite material has a constant size, namely 1*0,5 m. Furthermore the coating is made only of galvanized steel, top is covered with aluminum alloy. Further comprising protective compounds and mineral granulation, giving the appearance of natural tile.

Among the advantages of the material:

- non-flammable.

- Obuspechivaet good sound insulation.

- Low weight.

- Good aesthetic quality.

- A huge range of shapes and colors.

among the shortcomings:

- High price.

- More difficult and long installation, than the standard metal.

bituminous sheets

They are quite flexible sheets undulating texture. They are made of cellulose fibers, which is subsequently impregnated with a bituminous mastic.

Further, after manufacturing the front side is further coated with protective and paint compositions. Which are based on vinyl and acrylic polymer segments.

To date, the production of such materials has been quite a large number of companies. And, accordingly, there are many new variations, one of which are bitumen cardboard sheets.

onduline

The main of these, as the name becomes cardboard, further it is impregnated with bitumen and tamed decorative layer. Such sheets are called ondulin. The appearance of the material strongly resembles slate, but it has a number of inherent advantages in contrast:

- not fragile.

- Much easier.

- It has other dimensions.

- It does not emit harmful substance.

- This material is durable

- read

- economical

- It has a relatively small labor input.

The parameters of a single sheet: weight - 5,7 kg, width - 950 mm, length - 2000 mm. Ondulina lifespan long enough - 50 years old.

One of the main advantages of this material - ecological cleanliness, because it does not contain asbestos, and negative environmental resistance.

The material itself is recognized as one of the easiest of all the roofing.

Ondura

Another type noted Ondura - sheeting, which are used in the manufacture of bitumen and cellulosic board. From the outside Onduri sheets covered with a layer of special ink. When mounting is required to lay the additional waterproofing layer of rolled materials. Term life Onduri, compared with the usual slate, less, and artistic and decorative figures are much higher.

They are made of polycarbonate or poly vinyl chloride. This material is characterized by high decorative properties sufficiently, but its service life is relatively small - 10-15 years.

Light-transmitting sheet

Such material is made mainly from polycarbonate or PVC. At the core technology lies extrusion.

The material is gaining a lot of attention due to their design solutions, allowing you to create unique buildings. At the same time there is a short period of operation, to 15 years old.

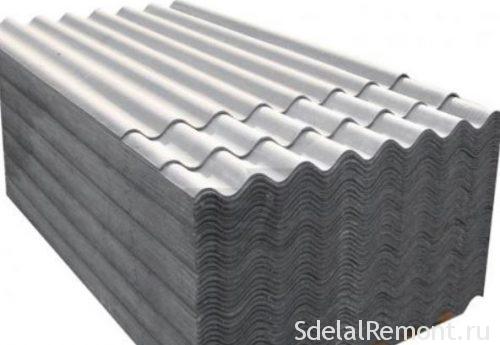

asbestos-cement sheets

The starting material for these is normal or colored cement with the addition of asbestos fibers.

Quality characteristics of asbestos-cement sheets are:

- durability

- ease

- strength

- impermeability

- fire resistance

- high resistance to alkalis.

Asbestos-cement flat sheets produced from uncolored feed, in which the pigment is added. They can be:

- light (unpressed)

- heavier (extruded)

- smooth

- painted enamel

- embossed.

Asbestos-cement flat sheets may have a length 1200, 2500, 3200, 3600 mm, thickness - 4, 5, 8, 10, 12 mm, width - 800, 1200, 1500 mm.

When the device roofing sheets laid along a continuous sheathing diagonally overlap

When the necessity descents and coating edges sheets can be cut to the desired size. that roof It was more reliable, Asbestos-cement sheets often under lay asphalt roofing or.

Corrugated asbestos sheets ordinary profile can be conventional, having the following parameters: weight - 8,5 kg, thickness - 5,5 mm, square - 1200 x 686 mm, or reinforced with thick - 8 mm, area 1000 x 2800, wave height - 50 mm. The corrugated sheets are compared to flat possess much greater strength due to the cross-section due to their rigidity.

Features slate

In the construction of roofs covered with such a material becomes optional device is the continuous purlin.

The standard size of the corrugated sheets with a thickness 5,5 mm of 1200 x 680 mm.

Mass conventional slate is 8,5 kg. In addition to his, issued also reinforced, products from which more durable and sturdy.

industry, in addition to the sheets, issued grooved elements for covering the ribs and the ridge.

There is a slate based on plastics. Distinctions made thereof roof - the ease and variety of colors.

Manufactured by compression plates have great strength due to its corrugated undulating surface.

The dimensions of the plate up 1000 x 1095 mm, its mass - 11,5 kg. In the production process it is stained in standard colors: the black, brown, red, Gray.

Seam roof

And the last one coating becomes folded roof. Like many other sheet materials, it requires a device inclination angle of not less than 12 degrees. The material itself is made of different components:

- Metal.

- Copper.

- Zinc.

- Galvanized steel.

Sheets bonded to each other via folds, which are made on site by hand. Quite often it is in the production strechayutsya embodiments articles of copper and zinc titanium. Because some species are called "Titanotsinkovye sheets".

Another kind is worth noting the brass plates, which are most popular. The disadvantage is getting pretty high cost, which results in a low percentage of popularization.

Such sheets are capable of stress and its expression construction architecture.

among the advantages of:

- Large operational period (more 100 years old).

- Good flexibility and elasticity.

- The high level of strength.

Among the shortcomings should be noted:

- the high cost.

- Over time, the material fades. First expressed vividly copper color, eventually it begins to darken, and after a few years acquires a peculiar bluish gray shade.

conclusion

As can be seen from every material has its own properties, which may be useful in certain circumstances, and not be necessary in other. Because the selection of the type of sheet material for roofing should do based on the characteristics of the region, where you live, and depending on the financial situation. In conclusion, we offer you to view several video clips about the kinds of sheet roofing materials.