To feel all the charm and comfort of your home comfort, space you need warm water floor, you can easily set their own hands. It is not so easy, both seem at first glance. If you are not familiar in the works of this type, you'd better contact the experts. Well, if you have decided on their own to do it all, this information is for you, shall understand which device, stacking technology and installation on their own and photo instruction. See also how to choose a warm floor right.

First of all it is necessary to draw up a draft, then make all the necessary calculations, associated with the load B of the heating STEM, and, for each room separately. Optimally to calculate water circuits floor. All these works should deal with people with experience of such structures device.

STEM, and, for each room separately. Optimally to calculate water circuits floor. All these works should deal with people with experience of such structures device.

Experience shows, device of warm water floor, best suitable for buildings such as country. In urban buildings before you line up a number of problems, associated with the connection to the central heating system,. It is prohibited by law.

The advantages include the fact, that exploiting the warm water floor, you significantly reduce the power consumption, which means, that cash costs decline. Besides, electromagnetic radiation, we get in large quantities, you and your loved ones will bypass.

Properly designed water floors have an advantage over floors, electrical, as the heat in the room will be evenly distributed.

Device

Each room is necessary to select the optimal system of floor heating. And their, as it is known - three.

- Installing using concrete screed.

- Installation without concrete screed - grazing technology. Here is a little more complicated, because the floor covering (linoleum, tile, laminate, etc.) fit through additional waterproofing (polyethylene foam, cardboard) on aluminum sheet.

- The latter type - a wooden. This installation of warm water on the floor slabs or blocks of wood - logs.

Complete system underfloor looks: flooring of thermally insulating material, Metal or plastic tubes, Clamping fittings, clutch kit, locknuts for compound, pump, creating pressure and circulation, and the enclosing element - concrete screed and the floor itself.

Installation with their own hands

The first technology - concrete. It is most commonly used among all other types of. Experience shows, warm water floors can make a man with his own hands, even slightly versed in plumbing and construction, and having a user manual at hand. Let's understand this installation technology.

What you need. First of all do the layout of our room. Sector should be approximately 40 m2.In this case, the parameters, influencing the temperature characteristics of the concrete screed, They will be offset.

Then laid on a floor slab or penoplex foam as insulation material. Thermal insulation is needed in order, that there is no heat loss. To compensate for thermal expansion of ties, the walls are paving the special tape. The next step will be the layout of reinforcing mesh, which is a bolt and the fixing member for pipes.

Now go to the distribution and installation of pipes. Many of the issues concerned, how to make Radiant floor with their hands so, so that the heat is spread evenly. It's simple. Pipes can be placed, How do you like, but mostly they are placed in a spiral or snake, shifting the center, shell. The photo below shows the basic embodiments of the floor laying of water pipes.

After laying the pipes in their turn attached to a reinforcing grid, using special clamps at a distance 90-100 cm. In order not to strain, Clamps can not be tightened strongly. Since when body heat expands, Consequently, can fail and our pipes.

For reference: stacked on pipe technology from each other at a distance 10-35 cm., off the wall, Floor water pipe should be at a certain distance and depends on the temperature of return water underfloor.

Assembly. The supply manifold insert and fasten the first end of the tube. Then, on the basis of the project, We laid along the contours of the pipe and fasten them to the above method. helix length should be approximately 50-60 m. When you are finished with the first circuit, insert the pipe end into the return manifold. The collector has to have as many outputs, how are you going to put contours.

To avoid problems in the future, installation of warm water floor should be carried out according to the instructions. When crossing the expansion joint pipes, located between the contours, to apply the corrugated hose or corrugated pipe.

finish the job, associated with the assembly and mounting hardware, We check the system for leaks. To do this, fill the tube with water and create a pressure above normal 1,5 fold (0,6 MPa). It would be better, If this test will be engaged professionals.

When warm water is completed floor device, you can begin to work with a coupler. There are many blends, it applies to underfloor heating, eg, Teplolux-GLIMS - one of the recommended. When the device screed pressure in the pipes must be working. As a result, your floor will rise to 5-7 cm.

Polystyrene system of water underfloor heating

This system is designed for rooms with low ceilings, consisting of polystyrene plates, in which grooves the heat distribution plates are inserted.

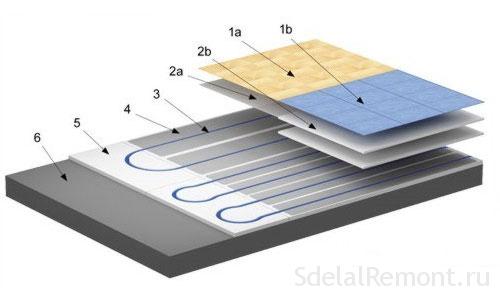

Stages overlay layers, depending on the topcoat - laminate, flooring or tile

| 1but. topcoat (parquet, laminate) | 1b. topcoat (tile) |

| 2but. pad (polyethylene foam, card, etc.) | 2b. The national team tie (GVL, CSP, etc.) |

| 3. Laying of floor heating pipes | 3. Laying of floor heating pipes |

| 4. Mounting plates of aluminum | 4. Mounting plates of aluminum |

| 5. Polystyrene insertion grooved pipe | 5. Polystyrene insertion grooved pipe |

| 6. basis | 6. basis |

In this way, installation of thermal water the floor with their hands will be executed on the following technology: Laid insulation on the floor slab. We need to start laying the angle, and in accordance with your plan, distribute all polystyrene plate in the room. Further these plates are mounted in the heat-distribution plate. On completion of the laying plates, pipe contours carefully inserted into the planting nests. Now they will be flush with the plates. The test can be carried out without ties. And if all goes well, remove, temporarily laid floor finishing, and do screed. Wooden floor heating system water.

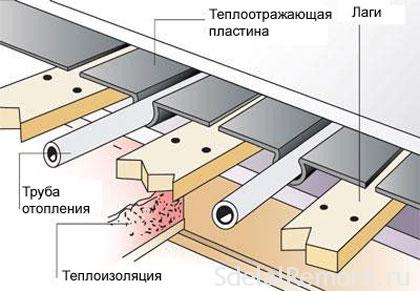

This technology is well suited for timber construction. In such a house a warm water floor with their hands do not difficult. Between the wooden logs stacked mineral wool or polystyrene, performing the function of thermal insulation.

You can apply a modular system type. This DSP design with the already prepared tube channels.

Or, reechnaya system, by the way, not too difficult. Between the plates of chipboard, pre-screwed to the base with screws, stacked plate, and the contours of the pipe. The width of the chipboard strips should be within 150-300 mm. The photo technology described in detail and stacking device wooden floor system water. In principle, there is nothing difficult, with their hands, you can do everything exactly the same.

The finish flooring laid over the aluminum sheets, on waterproofing material. Before you begin laying linoleum or laminate, on the aluminum plate travel along gypsum gasket.

In this way, you know the device of warm water floor and its installation can be done with their own hands, without the help of experts, if you have knowledge in this area and use the operating instructions of the site renovated apartment with his hands. Stay with us and learn a lot of useful information on repair. Leave a comment or share your experience.