- Which to choose a warm floor

- Types and Advantages of floor heating under a parquet

- Necessary materials for work

- Substrate preparation

- Arrangement of the insulating material

- Construction of room for the thermostat

- Laying film

- Insulation film sites

- Wiring and its testing

- system connection

- connect the thermostat

- system test

- Things to know when laying parquet on floor heating?

- Instructions for laying of floor heating

- conclusion

One of the most important issues - is heating the house, and it should be taken very seriously. It is due to the equipped right heating system will depend on the comfort of the room. And one of the most effective options is the arrangement of floor heating. And its installation may differ depending on the topcoat. Because choosing as coating parquet, you need to know, How is the underfloor heating installation under parquet, which system to choose and what to consider.

Which to choose a warm floor

Outset, that the words (parquet) means the panel board floating board. At all, better use of laminated wood and not feel the strength to temperature.

Natural flooring does not like humidity drops (maintaining optimum moisture 40-60%) and to heat is not recommended thereby dry tree.

To a parquet floorboard or not periodically appear slit, heating the board to be weak. Parquet boards should not be heated over 26 ºC. Manufacturers of solid parquet and floorboard claim, in order to avoid deformation of the wood and to maintain its service life in a room temperature difference between the coating and air should not exceed 2 ºC.

the norm +18 ºC for premises, the floor can not be heated over 20 ºC. At this temperature, the floors will not feel cold, for them it will be possible to walk barefoot. But the heat they generate is not enough, to warm the room during the cold season. And possible consequences of placing a warm floor under the floorboard.

The first question, which need to be addressed, This choice of floor heating under a parquet. The most commonly used power options, which are divided into three types:

- cable floor, which is installed in the upper tie (usually used for tiling).

- Reinforced cable floor, settling a tie.

- And film floor, which is placed directly under the floor covering.

In the case of parquet, if you do not need to replace ties frequently finds its application film floor, or as it is also called, infrared. But in its application, should take into account some factors, that affect the choice of flooring and:

- choosing parquet, you first need to pay attention to the resistance of wood to changes in temperature and humidity, from which it is made.

- An unsuitable parquet, during operation may cause cracks.

- For persistent species include oak wood, Duss, merbau.

- Also, do not stack too thick parquet. Because of this increased demand for a much larger heating installation and higher power underfloor.

- Provide advance, that heating power per square meter was not more 100 W.

- Before laying the parquet humidity should be minimal. Somewhere around 5%. If necessary produce drying.

- The room temperature must be equal to the temperature of parquet. To do this, it needs to be pre-positioned in the room, without removing from the package.

- Humidity of the premises, which is produced stowage, It should be about 50%.

With a choice of main type of floor heating sorted, but it is necessary to take into account the, that infrared floor is divided further into several varieties.

Types and Advantages of floor heating under a parquet

note, that a couple of years ago, the existence of the infrared floor knew not many, and today he reaches the peak of its popularity. And because there are more and new types of, today shared by only two types:

- carbonaceous, which is a member rezistovy, the production is carried out from a number of thermal elements, parallel connections of, and Mylar.

- Bimetallic, which is an alloy of copper and aluminum, coating a polyurethane film.

It should be noted that such systems are used for both sexes, and for walls and ceilings, since they possess a number of advantages:

- easy to install, a total work takes up to two hours.

- The material thickness of the entire 3 millimeter.

- It has a high level of reliability.

- It does not require a tie and everything is laid directly under the finish flooring.

- a little more economical, compared to other types of.

- Easily dismantled and installed again.

- Ionizes the air space.

- It has good elasticity.

Necessary materials for work

Basically, all the necessary materials are included with the film, and that:

- Immediately she thermo (sold in rolls).

- Insulation kit and clamps.

- wire.

- thermoregulator.

- temperature sensor.

Also, further recommended buy:

- Plastic film or rolled waterproofing material.

- masking tape (desirable bilateral).

- heat reflective material.

As you can see, materials is sufficiently small. but important choose the right foil substrate.

It is also worth pay attention to the instrument, which is also a bit:

- Scissors.

- Pliers.

- building a knife.

- drill.

- Pencil, roulette and ruler.

Substrate preparation

Before, how to begin to lay a parquet floor heating, necessary to conduct training base. It involves the following processes:

- Dismantling of old coatings and garbage collection.

- Leveling the floor if necessary.

- Marking places of wiring and installing thermostat.

After performing these processes, you can proceed directly to the installation of the floor, the process is divided into several stages, namely:

- insulation improvement

- Preparation of the site for the temperature controller.

- Laying film.

- Insulation cut portions.

- Wiring and system test.

- And in the end, laying laminate.

Now let us consider more in detail each step.

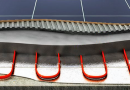

Arrangement of the insulating material

Firstly, after aligning the sex carried waterproofing device, to avoid exposure to moisture from the lower tier floor. To learn how to perform the waterproofing in a separate article.

Next, you need to provide thermal insulation, which will prevent heat loss. Because it is desirable to choose the reflective material. This will significantly reduce energy costs, at the same time increase the heating efficiency.

You can use almost any material, it is desirable to roll, It needs to be laid up metallized side. Considering Expert opinion on the choice of substrate, It becomes the best one special polyethylene foam (izolon) thickness from 2 millimeters.

Besides, You can also use non-reflective and insulation, eg, cork fabric. Such will be slightly less effective, but cheaper.

The only thing, not recommended to use insulation on the basis of the foil, because they are highly inefficient in this case,.

when installing, joints are recommended to seal metallized tape.

Construction of room for the thermostat

The next stage is the preparation of the site, where the thermostat floor heating will be installed, performs the following functions:

- temperature level of control and customization.

- Programming ON and OFF.

- Setting the temperature and heating support.

As to the place, we decided on a further phase of preparation covering, it is now necessary to make a recess in the wall to install the regulator, and to bring to it for further wiring connection.

Next, prepare the laying scheme and placement of the floor wire.

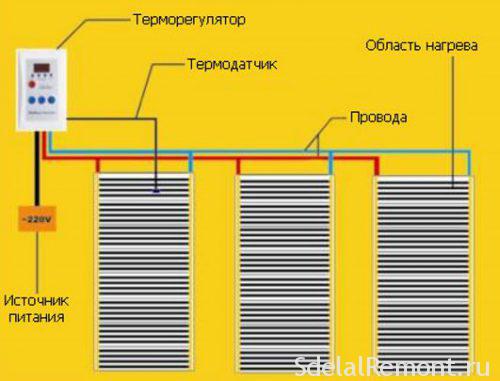

Laying film

Now it's time for direct laying of floor heating under a parquet. Yourself installation is carried out strictly according to a prearranged scheme. Below you can see an example of such a scheme, or even take it on board:

As mentioned, styling is carried out only on the desired area of the room, there, where there is no furniture. note, that directly arrangement of floor heating can be performed in two variations:

- Bet on 5-% space for supplementary heating, in the event of primary source.

- On 80% area, if it is planned to use the film as a main floor heater.

We consider the second option of laying, when it comes to the full heating. Work is carried out as follows::

- Pre decompose film (for convenience can be cut in the planned areas (it is important to cut only the white bands between the heating sections). The length of the audio band should not exceed 8 m.

- An important factor is the offset from the wall not less than 20 centimeters, in the presence of heaters, from them you need to retreat at least a meter.

- after layout, marks the spot, where there will be connections, and otcherchivaem wiring path.

- After applying marks Equips recess, and for wiring temperature sensors.

- Next film laid, Enhanced down, joints are held together by duct tape. Not in any way, must not, to the heating zones were adjusted at each other.

Insulation film sites

Further, to avoid possible short circuits and damage to the system, must be insulated space, incision was performed in which.

For these purposes, used asphalt mastic, or tape based on bitumen. The process is carried out as follows::

- Cut the piece of insulation required rectangular shape.

- the segment size should be slightly larger, than be insulated zone.

- In the film itself Do the small opening, which will serve for fixing, by pressing a heater.

- isolate, and fix, then, seal the top with tape.

It is worth noting, that place, which will connect wiring, at this stage, we are leaving open, because it will have to install the clamps and wires.

Wiring and its testing

Now you need to connect the system to the power supply, and test performance. Let us consider separately the two processes.

system connection

for system connection work is carried out as follows::

- Pre-made recess in the insulation, which will be installed wires. From the center of the wire must go to the plinth, and then displayed to the controller.

- The important factor is to provide complete immersion in the wire insulation, to avoid pressure on the wiring flooring. Otherwise, within a fairly short period of posting will be destroyed, and the work will have to redo.

- Besides, It increases the risk of circuit, it can and does spoil the whole system and create a fire hazard.

- The wires are laid along the channels, and subsequently fixed with tape.

- Further, the film clamps are connected. They are inserted between the film and the copper conductor. It is not recommended to clamp them directly to the wiring, because there is a great risk of damaging the film itself.

- Further, from the end of the wire insulation is removed, it is fed to the terminal, and inserted into it, pressing pliers.

- Connection is carried out in parallel, used for this purpose two separate wires. It is recommended to take a cable of different colors, not to be confused.

- Thus, one connected from the right side of the film, the second on the left.

- Next, place is isolated compound, and secured with adhesive tape.

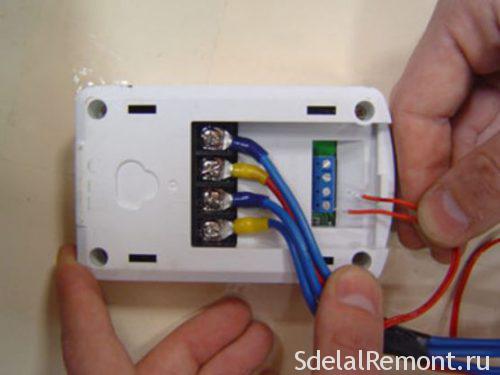

connect the thermostat

The next step is to connect the thermostat.

- First of all the temperature sensor is connected to the film, placing at the center section. It is a miniature thermometer, that will send reports on the state of the system temperature to the thermostat.

- As I mentioned earlier, it is necessary to prepare a hole, which drown, that he also, as the wires are located above the level of insulation.. If necessary, bend the wire, should prepare canals with smooth turn, the cable did not break down over time,.

Immediately after arrangement of the sensor, you must start the connection of the thermostat:

- It is recommended to install the controller permanently, connected directly to the power supply, but allowed the use of sockets.

- Summing wiring prepared to deepen in the wall, two wires connected to the main controller contacts.

- For the second pair of contact wires summing the film. Grounding terminal interconnectable, but it does not connect to the controller.

- Next, fix the controller in the niche, after the test can be carried out with a mixture of glue fixing or gemetikom.

system test

The final step, which is performed before the start of laying a floor covering, It becomes warm floor system test. For this:

- include it, setting a temperature in 30 degrees.

- Carefully examine the cover. It should be completely absent any sparks.

- Also check the level of heating, it should be the same at all sites. Testing is performed using a special tester.

- If the defects were not detected, It means the system is normal, and the installation was successful.

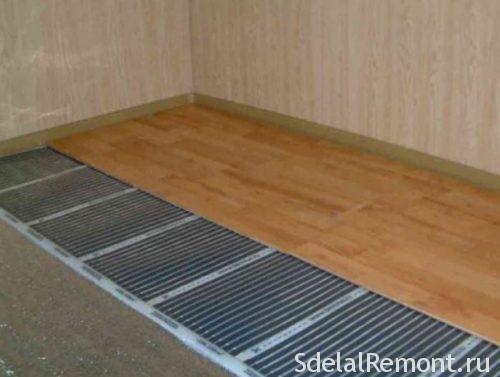

After successful testing, necessary to cover the entire surface with plastic wrap, which will act as a waterproofing, and in addition will reduce the wear and tear of heating elements. You can also use rolled waterproofing material, which will provide additional insulation and.

The installation of floor heating under a parquet completed, and you can start laying the coating itself, but there are a number of factors, which should take into account.

Things to know when laying parquet on floor heating?

- When laying need to work as carefully, so as not to damage the film underfloor heating.

- Before selecting the cover consult with a specialist.

- Also, be sure to check with the, how to lay parquet on floor heating.

- After completion of the laying, In no case can not immediately turn on the system, you must give the floor to reach room temperature, and only after that connect the floor to the network.

- Be sure to leave a small gap between the laminate and the walls, which will ensure the ventilation system.

Instructions for laying of floor heating

When working with such a system, as an infrared heat-insulated floor, should take into account a number of factors, which are undoubtedly important:

- Any installation work can carry only positive temperatures, wherein the air humidity should be more than 60%.

- Before connecting the film to the network, must be carefully, preferably several times, check out all the places of isolation and contact zones cutting the integrity and tightness.

- In no case can not be connected to the network film rolled up, or in the case of, when the strips lie on each other.

- If the damage zone of the film with a graphite filler, you must immediately insulate the surface on both sides.

- The system can not be installed on damp substrates.

- When, if there was a water leak (flooding) underfloor heating, you should immediately turn it off, disconnected from the mains and allow to dry naturally.

- At the end of the work sketch a layout of all the wires and strips of film, as it has been shown in practice, such a move is very important and useful in the future.

- According to the laid warm floor can not walk in shoes.

- Set the temperature sensor at the strip, in any case it does not brick, it must be on the edge, so you can easily replace if necessary.

conclusion

Now you know, independently arrange a warm floor under the parquet. In fact, the process is quite simple and fast, important to approach it with the utmost care. In conclusion, Here you can find video instructions for installing infrared floor.