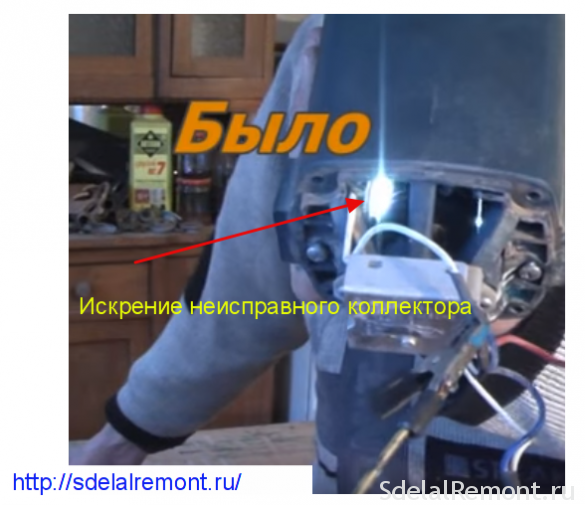

Correct operation of the gun Makita 2450 with commutator motors accompanied by a small amount of arcing of brushes in collector area. We regularly operating motor sparks even with a short tail.

By sparking a picture change can determine the nature and location of the fault in the punch Makita 2450, 2470.

The reasons for the increase in the collector sparking motor may be defective brushes and wear, a short circuit or open circuit armature, Faults on the stator windings of the electric motor, failure or improper fastening of brush holders.

Significant sparks in the collector region leads to the appearance of fissures on the collector, podhoranyyu plates, uneven abrasion of brushes.

The occurrence of these defects causes rapid wear and production of slats of a collector.

Since the hammer is a powerful tool, A small amount of arcing without load, with significant efforts on running a single tool possible sparks in a circle. In case of heavy sparking need to find out the cause of the strong sparking.

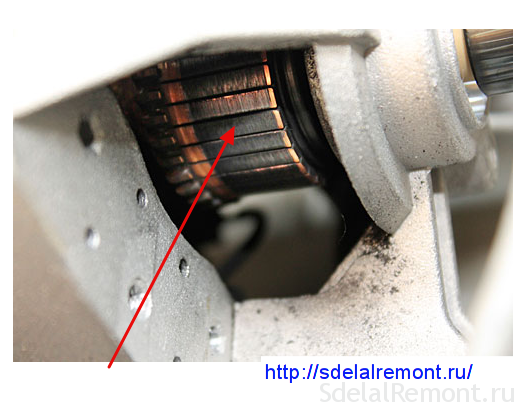

The most common malfunction of the collector is an increasing roughness of the slat when amplifying brush sparking.

Increased surface roughness perforator collector Makita 2450 It takes place not only by increasing spark. Copper plates on the collector is formed of copper oxide, on hardness exceeding hardness of the carbon brushes. The magnitude of the roughness affects uneven brush wear and carbon deposits from the spark.

Scratches formed not only due to uneven wear of the brushes and different structure of the material, but also to enter the working area of solid particles from air.

Improper storage perforator Makita may cause oxide on the copper plates of the collector due to high humidity or significant changes in temperature when operating.

To resolve the collector surface defects, it must be sanded.

How to polish the surface of the collector

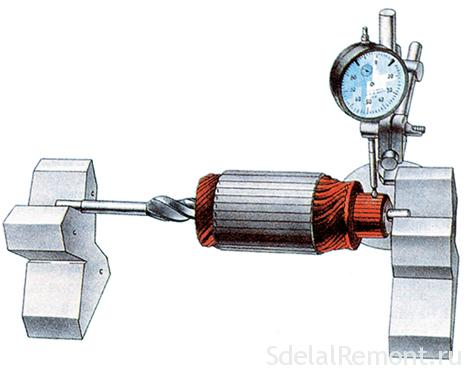

Before proceeding to finalize the collector punch Makita 2470, it is necessary to perform a balancing rotor.

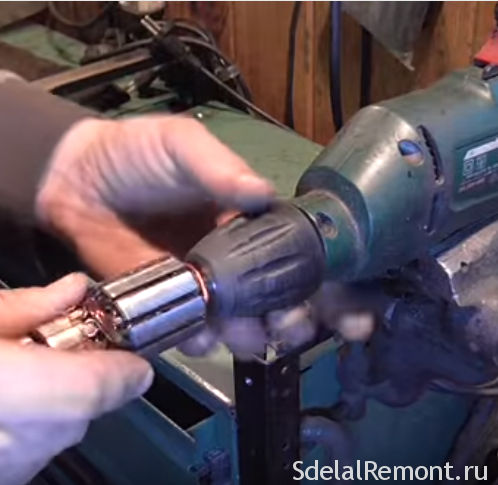

At home, grinding collector punch Makita 2450ili 2470 is best done with sandpaper, fixed on a wooden board already balanced rotor.

The end of the rotor shaft is mounted in the chuck drill through the soft copper or aluminum foil. Drill with the rotor fits securely in a vise or a homemade device.

rotating the rotor, try to center it in the drill chuck.

As center the rotor in the drill before grinding

Alignment rotor drill chuck is made to provide a minimum radial runout collector surface relative to the rotor shaft.

First, check the run-out of the cartridge jaw. Secure the drill in a vise, Set in a drill chuck of the large-diameter.

rotating drill, move to the side surface of the rotating drill pencil, Based on its simple focus. With a minimum heartbeat will outline pencil on the surface of the solid line drills. If palpation significant, change in drill chuck or a drill with a lower pick beating cartridge.

Now, instead of the drill hold the rotor shaft in the same manner and define a rotor space or manifold runout.

The grinding process collector

The process of grinding the collector must begin with the selection of emery material. Grinding collector is recommended to use sandpaper or needle file.

Choose sandpaper several rooms, №100 from above.

Now move on to sand. Applying to the collector of a wooden block with sandpaper attached, rotate the drill and, not strongly pressing block to the collector surface, grind.

Grinding operation is recommended to have worked with small rotors generation collector.

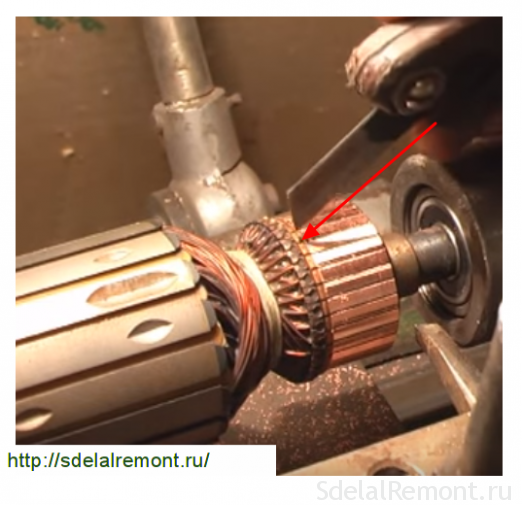

If you have made on the rotor rotary hammer Makita 2470 collector replacement, after its attachment to the shaft, Collector should be pierced. This operation is performed to eliminate the radial runout surface lamellas new collector relative to the armature shaft.

Collector eat through the best on a lathe using mandrels. But it is possible to perform this operation, and in the home. true, without additional devices oboytis.Video not help to understand the manifold groove.

Usually, brush holders on rotary hammers are mounted opposite each other. Continuous operation results in the formation of brushes on a collector grooves, forming undulations on the surface. Such production can be resolved only on a lathe, machined manifold.

To reduce the formation of grooves in the collector, you should try to brush holders arranged in a staggered manner.

How to clean the gun collector grooves

But the sweep of the grooves between fins should be carried out, as mica, gasket material between the segments, firmer copper slats and less wear. Over time Micanite pads wear out less, and their height exceeds the height of the copper slats.

To align the heights of the grooves between fins milled, or, in simple terms, prodorozhivayutsya.

Milling with your hands is best done with a piece of metal saw, honed width of the collector slots.

Parallel to the edge of the groove is applied metal ruler, Saw is pressed to the edge and stretched with low pressure. The groove is milled to a height of copper slats.

Milling grooves ends residue removing material using a hair brush and chamfering using the scraper, made of a Needle. Polishing felt better to do.

Any milling should finish grinding and blowing air.

The magnitude of the collector affects production and the bearings. Deterioration of the bearings leads to increased collector runout, which in turn leads to faster wear of carbon brushes. In order to eliminate the beats collector suspicious bearings should be replaced by new.

How to control the condition of brushes

Installing new carbon brushes, recommended necessarily grind them for a better fit to the collector surface.

It is best to adjust the carbon brushes in a homemade lapping. Lapping is a shaft, where the sandpaper is secured. The easiest way to perform a shaft diameter of the tree, equal to the diameter of the reservoir, machined workpiece on a lathe. Inside the shaft tightly metal rod inserted axially. The device is attached to an electric drill chuck, drill switched, and brushes are fed to a rotating sanding disc.

Adjustment should be carried out carefully, periodically applying the brush to the commutator rotor in order to check their lumen.

Priter brushes to the commutator, before installation it is recommended to check the correct mounting brush holders. Brush holders at the factory setting are set to neutral, that minimizes sparking on the collector. If no factory marks, the installation of the brush holder adjustment is performed by moving in the direction of the brush holder, opposite rotation of the rotor to a minimum spark formation.

Brushes should not hang out in the brush holder, and tightly pressed against the commutator bars. The pressing force of the control spring in the brush holder.

Increased arcing at the rotor collector may appear due to the short closure anchors, cliff armature coils, short-circuit windings on the armature housing. All these problems can be solved only with the major rotor repair.