The household is the most popular power tools drill. Using a reliable assistant can not only drill virtually any holes, but also cut space for the installation of electrical devices, including the socket, switches.

But for this you definitely need a set of drills. Issued drill to work with any materials.

In operation, the drill tupyatsya and need sharpening.

Placed below the material tells, how to sharpen a drill for metal in addition to sharpening watch the video options

What is drill and how to hone

To carry out drilling operations produced special tools, the most common of which is a drill.

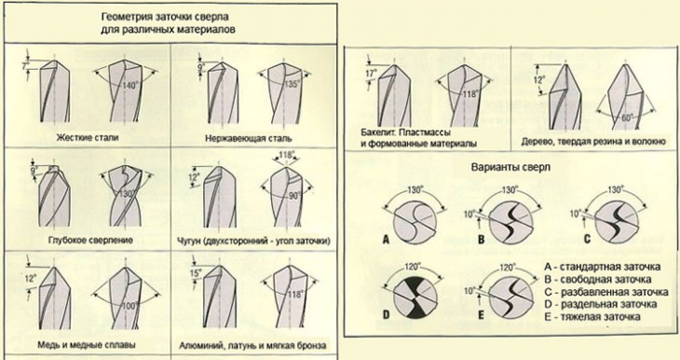

Attention! To work with different materials produced special drill bit with a different angle of sharpening drills.

Besides, grinding at angles affects the material structure. But first things first.

Drill called cutting tool, performing a cutting process by a rotary motion with axial flow.

Drills are used not only for making the through-holes of different diameters, but also for the reaming of the existing drill otverstiy.Primenyaya, you can drill through hole, make a hole of the desired diameter, Porting to perform to the required depth.

But to carry out these works, you will need the right diameter drill.

In addition, the drill must be properly sharpened.

And in order to learn, how to sharpen a drill, it is necessary to clarify, for any material tool will be used.

Structurally drills manufactured coil, flat or feather, ring, pivot, for deep or unilateral cutting.

Twist drills are available in various diameters. The range of 0.1 ... 80 mm when the length of the working part to 275 mm.

Flat drill used for the manufacture of large diameter holes at greater depths. Structurally, the cutting portion is formed as a blade, is attached to a holder.

Annular drill embodied as a hollow tube, whose works narrow circular cutting part.

Centering drills are used for centering during turning parts.

But all of these tools in the process tupyatsya. And once the drill tupyatsya, they must sharpen. And to learn, how to sharpen a drill, We have to submit, for what material will be used this tool and odes to change the sharpening angle of inclination.

Least likely tupyatsya drill when working on wood. If you use the drill only when the tree Porting, then these drills do not require sharpening for several months or years. It is only necessary to take care of their storage and use.

For us it is important to learn to sharpen drill bits when working on metal, concrete.

Sharpen drill bits for metal

To find out, how to sharpen a drill for metal, enough to watch a video about how the corners and sharpening.

To perform grinding work, it is necessary to have not only grinding equipment, but also a means of protection.

Of protection it is necessary to purchase eyewear.

A sharpening of the drill is best to buy a grinding machine.

A few words about Sharpening

Most often grinding machine is manufactured on the basis of a small AC motor 220 at.

Rotational speed of the grinding machine from 1500 rev / min.

The machine must be equipped with a mandatory transparent protective screen, glide.

At home, do not use a drill diameter of more than 16 mm.

So how to properly sharpen a drill for metal, if the drill blunted?

About tom, that require sharpening drill, It can be judged by there is a characteristic squeak when drilling, especially in its early. At the same time the drill begins to heat up, which further leads to its abrasion.

Sharpening drills on special grinding machines. At home, the drill can be sharpened on a stone with a simple winepress, using a grinder with an attachment, on sandpaper.

so, how to sharpen a drill for metal?

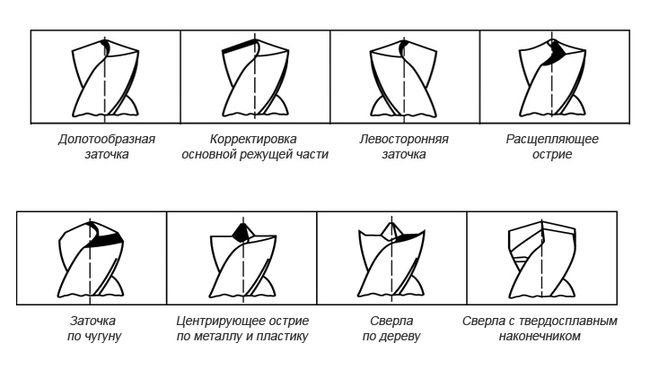

How to sharpen a drill, determines the shape of the rear plane of the drill.

The fact, that the sharpening of the drill is carried on the back side.

Attention! A correctly sharpened drill bit has two teeth, sharpened exactly the same.Speaking about the kinds of sharpening, note, that their will be several.

Simplest, odnoploskostnoy.

To perform monoplanar sharpening drill presses the cutting portion parallel to the grinding wheel. In the process of sharpening it is prohibited to move or rotate the drill bit.

This is the easiest type of sharpening. But it is recommended to use for drill diameter up to 3 mm. The biggest disadvantage of this type of destruction is considered sharpening the cutting edge of the drill during operation as a powdering.

The second common type of sharpening is called conical.

This type is used for sharpening drill diameter over 3 mm. This is a more complex form of sharpening.

Conical sharpening drills difficult to perform manually.

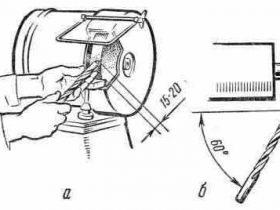

For its performance, we must take the bit in your left hand, holding a working part. Right hand clamped shank.

The drill bit is pressed against the cutting edge to the end of the grinding wheel at the desired angle.

Shaking his right hand drill, create a tapered surface at the rear face of the drill.

Attention! Smooth and slow movements of hands sharpen drill pen, without removing it from the surface of the stone.

These steps follow and for the second part of the drill.

Keep an eye on maintaining shape of the rear face and the sharpening angle.

To accurately measure the sharpening angles, use a special device, called a goniometer.

If the meter is not, you can make a template.

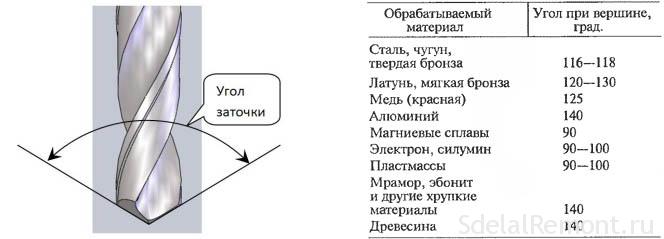

And what is necessary to maintain the angles, where they learn the value of.

sharpening angle drill for metal selected from the table.

Important! In the process, do not overheat drill, overheating leads to weakening of steel. Make sure the cooling and quenching with water.

To provide the desired angle of sharpening drills, it is recommended to use special tools.

Device allows sharpening angles drill with maintaining tables of requirements.

Methods for sharpening drills grinder at home, their own hands

About sharpening drill using a whetstone we reviewed. And how to sharpen a drill?

If not at hand grinding machine, you can do Bulgarian.

way of 1

This method is, that the drill bit rigidly mounted in a vise or device. Sets fastening angle.

On grinders mounted drive to work on metal. The rotating disk periodically supplied to the drill plane.

How to sharpen a drill grinder, well illustrated in the proposed video.

Attention! The proposed option is unsafe. Better and safer will, if secured in a drill device or a vise.

way of 2

In this method, the sharpening is attached bolgarka. On grinders mounted disk with fine sandpaper.

Hand held drill, is applied to the disk by the cutting portion.

All perfectly clear, how to sharpen a drill for metal grinder on video.

Rules pobeditovye sharpening drills

How to sharpen a drill pobeditovoe? Pobeditovoe drill is most often used for drilling holes in concrete, brick, stone.

In operation, the drill bit heats, izdavaya vizzhashtiy sound. This is the first sign of, that the drill need sharpening.

Detail about how, how to sharpen a drill to punch pobeditovye.

To sharpen drill pobeditovoe, better to use a grinding machine with diamond blade. Attention! Try to withstand sharpening angle. For drills it is pobeditovye 170º.

Sharpening pobeditovye drill is blunt trimming cutting edge.

Working with emery

Smooth touch drill grinding stones to tweak the front surface of the drill.

The drill is taken in the left hand near the cutting part, right hand holds on to the shank. The drill is fed to the grinding stones, Cutting disc grinder or the fungus established with emery cloth. Sharpening is trimming cutting edge drill pobeditovye, Porting that when a solid surface blunted.

Sharpening is trimming cutting edge drill pobeditovye, Porting that when a solid surface blunted.

Attention! It must be remembered, that the grinding stone speed depends on the hardness of the drill. The harder the material the drill, that must rotate slower drive.

In the process of sharpening you need to follow the identical cutting sides. Otherwise, you will get increased and irregular holes. It is important not to overheat and cool the drill bit.

findings:

-

- - drill can be ground correctly and in the home itself;

-

- - Drill up 3 mm preferably sharpened monoplanar view sharpening;

-

- - Drill over 3 mm recommended conical sharpener;

-

- - can be used for grinding not only special equipment, but also with an emery grinder attachment;

-

- - sharpening drills pobeditovye best produce on grinding machines with diamond blade;

-

- - When sharpening be sure to use goggles.

Video matched on sharpening drills in different ways