A hoist is a lifting device, designed for lifting and moving loads. Hoists can have different designs and be used in various industries. Depending on design and application, There are several types of hoists.

Manual hoists

Manual hoists are divided into two main types - chain and rope. Chain hoists are usually used for heavy loads, providing strength and long service life. Rope hoists are lightweight and maneuverable, making them an excellent choice for lighter loads. Large selection of hoists https://lebedki.by/tali/ruchnaya/

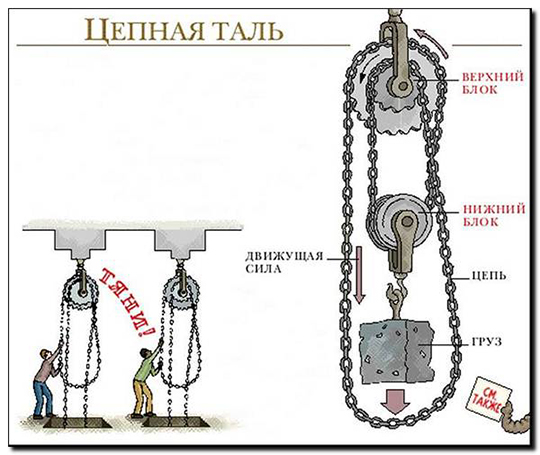

Principle of operation

Manual hoists are based on simple mechanisms. When the handle or rod is lifted, the chain or rope moves through the lifting mechanism, which causes the load to rise. Lift height adjustment is usually done by turning the handle. A chain hoist consists of two blocks and a chain thrown between them. There is a chain sprocket on the lower block, and on the upper block there are two stars of different diameters. It is because of the difference in the diameters of the sprockets that the load is lifted more efficiently. In addition, we should not forget about increasing the efficiency of the hoist due to the block system.

Advantages of manual hoists

- Portability: Manual hoists are compact and lightweight, making them easy to move around the work area.

- Ease of use: Operators can quickly master the technique of working with manual hoists without the need for special training.

- Reliability: The minimum number of moving parts and durable materials make manual hoists reliable and durable.

Areas of use

- Building: For lifting building materials and equipment.

- Storage facilities: For moving and storing goods.

- Production: In production workshops for processing and moving raw materials and finished products.

Specifications

- load capacity: From several hundred kilograms to several tons, depending on model.

- Lift length: Manual hoists provide different lift length options, which allows you to choose the appropriate option for specific tasks.

- Operators must follow safety rules when using manual hoists, including checking the condition of the equipment before each use.

Manual hoists are an indispensable tool for ensuring efficient and safe movement of goods in various industries. The choice of the appropriate model depends on the specific requirements and characteristics of the task.

Principle of operation: Manual mechanical system, usually with a handle, used for lifting and moving loads.

application: Ideal for small tasks, requiring precision and ease of control. Often used on construction sites and in installation work.

Benefits: Portability, ease of use, economy.

Chain hoists

Chain hoists are load-lifting devices, using a chain as the main element for lifting and moving loads. They are durable and reliable mechanisms, which are widely used in industry for various lifting tasks, detail https://lebedki.by/tali/ruchnaya/tsepnye/

The design uses a chain to lift the load. Suitable for heavy loads and operating conditions, requiring strength and reliability. Widely used in construction and industry.

Manual chain hoists are reliable and efficient lifting equipment, widely used in various industries. They provide operators with an easy and safe way to lift and move heavy loads. Let's consider the main characteristics and types of manual chain hoists.

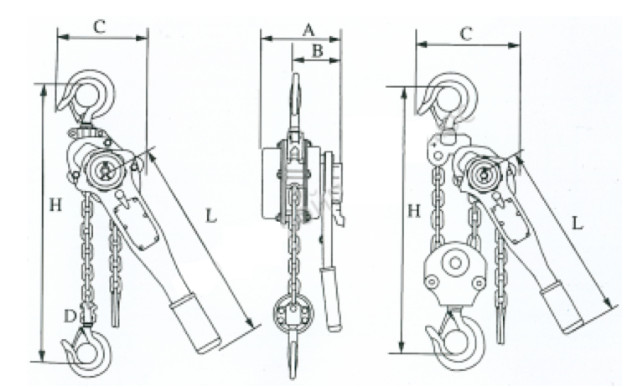

Structure of manual chain hoists

- Chain: Main lifting element, made of durable steel links.

- Load chain: Tied to the load and passes through the lifting mechanism.

- Lifting mechanism: Includes gears and gear sliders, providing lifting force.

- Lever: Used to operate the lifting mechanism.

Types of manual chain hoists

- Single manual chain hoists: They have one chain and are designed for lifting relatively light loads. Lightweight and portable, They are ideal for installation and repair work.

- Double manual chain hoists: Equipped with two chains and designed for heavier loads. Provides increased lifting capacity and stability when lifting.

Advantages of manual chain hoists

- Strength: Made from high strength steel, ensuring reliability and long service life.

- Ease of use: Does not require complex installation or special skills. The operator can quickly master the operating technique.

- Versatility: Suitable for use in various sectors, including construction, warehousing and production.

Specifications

- load capacity: From several hundred kilograms to several tons, depending on model.

- Chain length: Manual chain hoists provide different chain length options to adapt to specific applications.

Application of manual chain hoists

- Building: For lifting and moving building materials.

- Production: In production workshops for manipulating equipment.

- Storage facilities: For moving and storing heavy loads.

Security

Before use, carry out a visual inspection of the chain and lifting mechanism.. The operator must follow all safety instructions, including proper load distribution. Manual chain hoists provide an efficient and safe solution for lifting loads in a variety of scenarios, ensuring efficiency and reliability in everyday tasks.

The choice of a specific type of hoist depends on the nature of the tasks, type of cargo, operating conditions and safety requirements.