Billiards is one of the most popular games around the world. And to this day a great pleasure for the game in the company of friends. But, Unfortunately, the cost per hour is large enough, and even at home to play much more interesting, rather than go somewhere. And often it happens, that in a small town and not at all billiard. But what compulsive gamblers, who more than once visited this wonderful atmosphere and feel the passion of the process, scoring another ball in the hole. there is an exit. Billiard table with their hands, you can do so just, as a cabinet or bedside table.

Only here you will have to exert a little more effort and perseverance, because it is essentially a luxury item and should be suitable to look. But do not count on 100% achieving results on the first try. After the creation of billiard tables was not just a profession for many, and art, which can be mastered, just spent a lot of time to practice, and created more than one such table. And all the better and more beautiful it will turn out each time.

Where to begin

For, to make a good billiard table with his hands drawings are not necessarily be self. A lot of them can be found on the Internet, with friends or masters, eventually, seek the assistance of an experienced carpenter. He certainly tell and show, how to start, how to calculate the ribs.

After all, a pool table should be as durable and heavy, so that when the game it does not vibrate and is not skewed at the support it. Therefore, many immediately raises the first question, how to make a billiard table with his hands, that he was strong, durable, regular geometric parameters and the most functional.

Game table - it is also the element of the interior, so it must be done in the style of design space. As it happens, the room is very small, and it must fit not only a pool table, but also auxiliary furniture, you should design it collapsible.

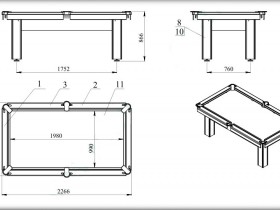

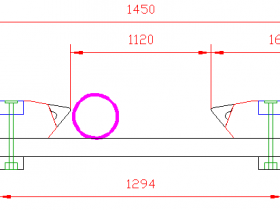

Generally, according to the location and spatial abilities. Likewise, its overall dimensions. It is considered optimal height 80 cm, length 2 m and width 1 m. And if you will get 0,83 × 190 × 90, I'm sure, and that you will not feel the difference from the original.

materials

For, to make a billiard table with his hands require, respectively, and high-quality materials. Previously, as they used only high-quality solid wood noble breeds, eg, oak or beech. The cheaper models are used more accessible and easier to handle rocks, eg, Sosna. While the table was completely taken out of it, starting from the feet and ending with worktop. Today, as the countertops are cheaper and much easier to use chipboard thickness not less than 18 mm. And can be thicker, It will be even more reliable, but the table will be much harder.

List of materials:

- solid wood (rails and trims from it) bead;

- LDRI (tabletop, supporting structure and legs);

- metal braces-lining for pockets;

- fabric lining and decorative;

- hardware;

- Grid for pockets;

- tires for impact edge;

- adjustable feet.

The list may not include all materials, so be ready, for something to buy more.

Beginning of work

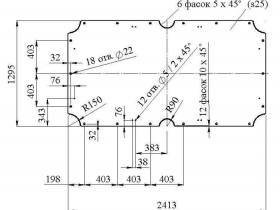

How to make a billiard table with his hands drawings where to find the most suitable. Yet once again, that the sizes may differ, so it is wise to develop their own. But also all the technical documentation on the pool table can be found in large quantities on the Internet, including on this site.

Having dealt with the theory begin to practice

The first stage is cut chipboard, This can be done in the same organization, where he was bought. This service is not as expensive, so it is quite possible to use. The more that the professional equipment you are guaranteed 100% geometry compliance.

Further, manufacture of billiard table with his hands turns into a stage of assembly of the whole structure. Usually, one standard sheet of chipboard is just enough to cover the support structure and with the sidewalls. At the same worktop may be dimensioned 2,18 × 1,18 m, and the elements of the support structure from the remainder of the just obtained by 13,5 cm.

Many at this point ask "how to make a support structure, To get a strong pool table, how to properly mount all the elements, that design does not play?"And the answer is in fact quite simple.

the main thing, to the supporting structure had at least 3 stiffening rib, t. it is. it can be done in a grid, and all the elements to be bonded to each other with ties sizing ends. Then necessarily need to strengthen the construction of small wooden cubes metal corners. The bottom is not visible.

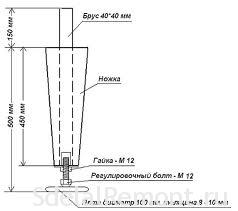

As the legs must use reliable and thick items made of solid wood. It may be not less than the thickness of the bars 100 × 100 see in my mind. They can be carved or sheathe perform the same chipboard followed trim edges.

Decorative part

To repair the pool table with his hands did not catch you by surprise during the game, all actions necessary to produce maximum quality and in good faith, because itself is doing.

Board game table is a decorative part and, usually, It consists of a plurality of elements:

- bead;

- outer trim strip;

- visible decorative slats with rubber baffle glued and covered with a green cloth;

- below there nakladochnye strips from the same laminated chipboard, to increase the stiffness of the whole structure upon impact.

If you make a billiard table with his hands, a photo, presented on the site, will help you in difficult times. Because they depict all the most important moments with the necessary details.

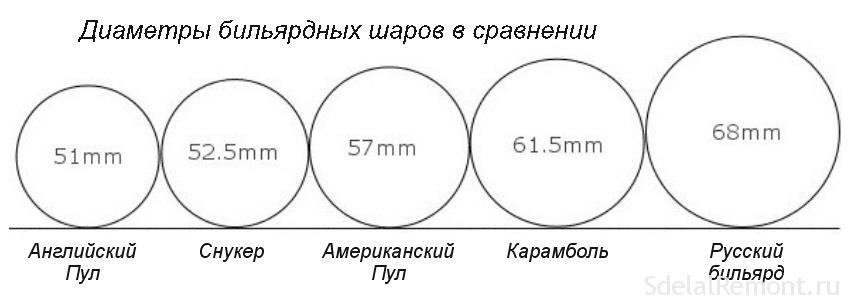

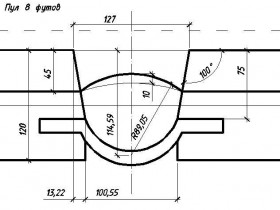

Prior to installation, the boards must be made in the table top slot pockets with the help of a jigsaw. Usually, their width is 90 mm at a rate of balls 60,3 mm. Corner Pocket is made with a small extension to the edges. This will allow 100% to get the ball into it in a collision on the inner walls. Then you need to glue backing fabric on the playing field, Decorative painting is to be stretched and fastened with staples to the table top.

When actions are completed with a cover, should switch to close-fitting sides and processing of decorative strips. Board, as it is known from the article, It consists of a rubber baffle, decorative rails and profile rails, to which is attached, this is the rubber. One of the most expensive materials is just exactly this tire.

For achievement 100% compliance with professional billiards, it is necessary to acquire the original. But since it is very expensive, you can use the belt from tractor. If you cut it in half lengthwise, it would be enough for the entire perimeter. Glued it on a high quality natural glue, eg, moment. Before wrapped with the resulting structure to be treated with sandpaper. Cloth on the billiard table is constantly subjected to mechanical shock. Therefore, fixing is carried out on the sides of screws or through bolts. Then hauling billiard alone will not be easy, if necessary.

After fixing the boards, you are ready to install the metal clips and pockets. staples beautiful, reputedly, will look in leather sheath. A plus, This will soften the blows of the balls themselves bracket. At this stage the mesh and is attached to pockets, which can be woven as yourself, but you can buy in the store, something like that. Here, in particular the strength of it makes no sense, the main thing, to the ground balls do not fall.

If you make a billiard table with his hands, Video will be an indispensable assistant, because in the paper we present only the general principles.

Testing for strength or moment of truth

A properly designed and assembled a pool table in good faith should not sink under the load, vibrate and resonate when falling on the surface of the heavy balls.

The table should be set at the level, for this leg should be given this opportunity. They can also make their own, for it in the store purchased durable wheels on the bracket. Usually, they have a stud, which must be screwed into the nut or clip. It can be made from a bent piece of metal in the profile and welded nuts.

Correctly selected tires does not allow the ball to bounce away from the board while the board does not deteriorate.

Pool table is very not cheap, to put it mildly, and that, that it can be done with their own hands is a great course, but it is not easy! My uncle once was carried away in the garage and a pool table wanted to put a pool table, when I looked at them the price, beginning changed his mind, but a couple of days for him had the idea to do it yourself. Then these sites has not been, drawing, Calculating all by myself. He began to make a table and even made a hole, left then sheathing it and finish the very decor, but my uncle went, and the table and remained. By the way it is often parents sat, when you have done kebab)) Although somewhat useful. But if we now do again and yet to complete the table, then there is a maximum working week, Behold my mother only pricey, as for me, easier to go and play in the cafe!