When choosing the right building material, we suggest using the right mixtures rationally and with a deliberate approach.. With a reasonable approach, repairs will be much cheaper, rather than simply relying on the advice of friends or consultants. Including, we warn you, against the use of complex combinations of different materials and technical characteristics. Better to use time tested draft materials for repairs, on different surfaces. As a rule, the quality of repairs depends on the choice of building material and adherence to technological instructions for application..

The choice of the type of putty

Consider the main types of putties and technological features of the application and implementation of application work.

Putty is a material, without which no serious repair can do. Consider the differences in putties in composition.

According to the composition, putty is divided into 3 species:

- plaster;

- cement;

- polymeric.

Gypsum putty

It's perfect for finishing walls., with its help, you can prepare the most even surface, since such putty is very plastic and has a small fraction of constituent elements. This type of putty absorbs excess moisture in the room., and then gives it back. Significantly accelerates the providence of finishing work.

Significantly accelerates the providence of finishing work.

Positive sides:

- aligns remarkably;

- fire resistance;

- quick drying;

- environmental friendliness;

- acceptable price;

- improved thermal insulation;

- slight shrinkage after application.

In addition to the pros, there are also disadvantages of gypsum mixture. It cannot be used in high humidity conditions., as it is unstable to water and temperature changes. When in contact with metals, the oxidation process is accelerated, therefore there is a possibility of rust stains. The strength of this type of putty is not very high.. With inexperience and improper organization of the order of work on puttying, material is overused and simply freezes in a bucket.

Council. Mixing small amounts of putty. To avoid rust stains, be sure to paint over the mesh reinforcement with enamel, etc..

cement putty

Cement putties are made up of sand, cement and water, which are mixed with each other in certain proportions. Sand is used by river, fine fraction, marks M400, M500. These mixtures can be purchased everywhere in any hardware store in dry form..

Benefits:

- humidity (ideal for bathroom decoration, pools, kitchens);

- frost-resistance;

- acceptable price;

- used for façade work;

- high strength indicators.

The disadvantages include low elasticity, coarse grain, the possibility of microcracks on the surface, shrinkage ability, poor contact with smooth surfaces, drying time.

In preparation for work, at least moistening the surface with water or mandatory priming is mandatory.

Polymer putty

Manufactured using polymer additives. Has the best properties, but higher price. Classified according to polymer, included in.

Acrylic putty is a versatile mixture. It can be used to putty anything.: wood, metal, brick, concrete, cement, drywall and other surfaces. This composition is suitable for both internal, and for external works, tolerates moisture well, tolerates moisture well, tolerates moisture well, tolerates moisture well. tolerates moisture well 1 mm, tolerates moisture well, Therefore, it is often used for finishing the room.. Therefore, it is often used for finishing the room., Therefore, it is often used for finishing the room..

Latex putty is made from acrylate latex., Latex putty is made from acrylate latex., Latex putty is made from acrylate latex., Latex putty is made from acrylate latex., Latex putty is made from acrylate latex.. Recommended thickness - up to 5 mm, Recommended thickness - up to. Recommended thickness - up to, as it has poor resistance to external influences.

as it has poor resistance to external influences, as it has poor resistance to external influences, as it has poor resistance to external influences. Suitable for brick and concrete surfaces.

Suitable for brick and concrete surfaces, Suitable for brick and concrete surfaces, Suitable for brick and concrete surfaces, Suitable for brick and concrete surfaces, since a certain type of mixture is suitable for each specific case.

Benefits: since a certain type of mixture is suitable for each specific case. since a certain type of mixture is suitable for each specific case. High quality material and great for home use, special, High quality material and great for home use. Used for interior work. Used for interior work, plasterboard, concrete, Used for interior work, Used for interior work. Used for interior work, and a thin layer.

and a thin layer, and a thin layer, and a thin layer, and a thin layer, and a thin layer, and a thin layer. Usually, to save money, the surface is leveled with Vtetonite in bags., Usually, to save money, the surface is leveled with Vtetonite in bags., hruntuyut, Usually, to save money, the surface is leveled with Vtetonite in bags.. Multi-finish ready-made putties are used, Multi-finish ready-made putties are used.

The order of providing work on puttying

Multi-finish ready-made putties are used ( Multi-finish ready-made putties are used) - useful for leveling and filling cracks, - useful for leveling and filling cracks. - useful for leveling and filling cracks. - useful for leveling and filling cracks. Consider the order of providing work, Consider the order of providing work.

Consider the order of providing work. To seal hard-to-reach places, professionals use strips, To seal hard-to-reach places, professionals use strips. To seal hard-to-reach places, professionals use strips. Of course, All tools must be clean before starting work..

All tools must be clean before starting work.. All tools must be clean before starting work., dry and previously stripped of paint. dry and previously stripped of paint, dry and previously stripped of paint, dry and previously stripped of paint, dry and previously stripped of paint, dry and previously stripped of paint. Glossy surfaces are sanded to a matte finish, Glossy surfaces are sanded to a matte finish.

Glossy surfaces are sanded to a matte finish primed ground: one or two coats will be enough, one or two coats will be enough, one or two coats will be enough.

one or two coats will be enough. The technology of "closing" the putty is convenient and quite simple, The technology of "closing" the putty is convenient and quite simple. The technology of "closing" the putty is convenient and quite simple, it should be at room temperature, it should be at room temperature, it should be at room temperature, it should be at room temperature.

Follow, Follow. Follow, Follow. The required proportions of the dry mixture and water are indicated in the instructions for use or on the packaging..

The required proportions of the dry mixture and water are indicated in the instructions for use or on the packaging., which has a screw stirrer. which has a screw stirrer. The mixture should turn out like a paste-like homogeneous mass..

The mixture should turn out like a paste-like homogeneous mass., The mixture should turn out like a paste-like homogeneous mass., The mixture should turn out like a paste-like homogeneous mass., about 2-4 minutes. about 2-4 minutes.

Usually, this resulting mixture is suitable for use within a few hours after its preparation. this resulting mixture is suitable for use within a few hours after its preparation, this resulting mixture is suitable for use within a few hours after its preparation, damp cloth.

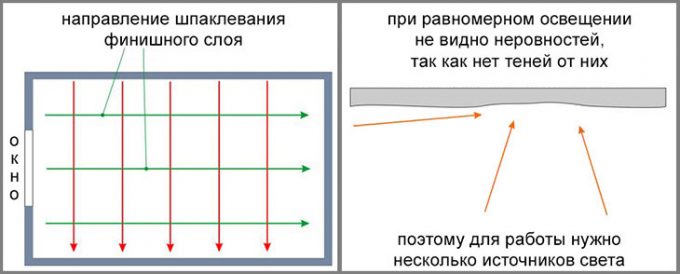

damp cloth. damp cloth. damp cloth. When applying putty on the wall, When applying putty on the wall. When applying putty on the wall, When applying putty on the wall 1 to 3 time. It is necessary to level until a very thin layer is obtained..

It is necessary to level until a very thin layer is obtained.. If the wall is painted afterwards, If the wall is painted afterwards, If the wall is painted afterwards.

The final stage - cleaning. The final stage - cleaning, The final stage - cleaning. To make the wall surface smooth, To make the wall surface smooth. To make the wall surface smooth. To make the wall surface smooth, now you can apply finishing material.