Works on plaster foam block inside the building - an important stage of repairs. With their help protect the wall material from moisture and, in this way, retain the basic parameters - water vapor permeability and lightness. When carrying out the main thing - to choose the right materials and technology to comply with.

Internal plaster foam block: how to do it right?

The design of any dwelling house one of the main elements are the walls. And one of the most popular modern materials for them is foam. Advantages of foam concrete blocks are in their affordable price, lightness and a good thermal characteristics. However, in order to preserve the benefits of walling should perform their finish. The main way to do this - plaster foam block inside and out. And, given the high humidity, which is created during the works, primarily executed interior.

Features Foam concrete walls

Due to the fact that the foam is made of cement grout, in which by means of a special technology involved air microbubbles, One of its characteristics is the ability to "breathe". it, in turn, It allows to provide optimum humidity level smokers. Another plus - high fire resistance and, in the same time, impermeability. In this way, during a fire do not burn foam blocks, and in contact with walls of water it quickly evaporates, without damaging the structure.

It is worth noting the absence of foam concrete on the walls of the mold, and high heat- and sound insulation properties. Therefore, such a material would be the best option, and for housing in the northern latitudes, and for buildings on a busy noisy street. And, construction of structures made of foam blocks cost faster and cheaper at the expense of their ease - for the construction of the house does not require any expensive and too strong foundation, no heavy lifting equipment. Moreover, the owners of the building will save more on heating and, and in further repairs. And one of the few problems, that may occur during construction, a plaster walls of the foam blocks, you want to perform correctly, carefully and with suitable materials.

The need for a plaster

One side, a stage as the plaster walls of the foam blocks inside and outside can be avoided. However, in this case, you may receive the following problems:

- unprotected constructs will be exposed to sudden temperature changes and precipitation, gradually collapsing and losing its quality;

- rising humidity will increase the weight of the walls and lead to subsidence at home, the foundation of which is not designed for such loads.

Another minus unplastered block is shown only in the molded articles and is too smooth surface, on which rests not every plaster. For this reason, foam trim only special materials. And be sure to finish hruntuyut, removing sutures and possible irregularities (which occur even in the molded foam blocks, but it is especially characteristic of the cut). However, after the plaster foam blocks made in, according to technology, the walls are not only protected, but also perfectly straight.

Preparation for work

Before plastering foam block, select the appropriate tools and materials. Firstly, during the work can not do without the most plaster, the material for the primer and a special grid. And to inventory, which is needed to perform the work, carry:

- construction mixers;

- buckets;

- spatulas;

- levels and plumb lines;

- dowel;

- washers;

- nails;

- spatulas;

- Metal brushes;

- knives and rules.

choosing, than to plaster the walls of foam blocks inside, pay attention to the primer. This material is selected among mixtures, specifically designed to trim foam, which must possess certain properties. First of all, high degree of adhesion, to provide a comfortable degree of leakage of the material inside the block. To meet such a primer may be in the range of product brands such as Knauf, IVSIL, UNIS and Prime-Primer.

As a plaster of concrete blocks can be used alone inner premix, as part of which contains chalk, cement and lime. but, possessing characteristics majority, suitable for finishing foam blocks, it will have one major drawback - the instability to the impact of frost and fire. Therefore, for the interior trim is recommended to prefer ready-made plasters brands such as Ceresit CT24, EuroMix or mask mix. These same materials are recommended for exterior walls. In details, how to prepare a plaster wall grout.

| Name | Type of | pre-packing, l | approximate cost |

|---|---|---|---|

| Ceresit CT 19 | Water-dispersionnaya, for treating the walls of foam | 15 | 730 rub. |

| Litokol PRIMER C-m | Deep penetration for internal works | 10 | 720 rub. |

| Thomsit R 777 | Firming primer for absorbent substrates inside the building | 10 | 860 rub. |

| Putzgrund RD313 | Diluted acrylic primer for interior and exterior use | 10 | 800 rub. |

| Terragrunt | 20 | 1620 rub. | |

| LAKRA coat universal deep penetration | Impregnation with additives against mold | 10 | 440 rub. |

| Tikkurila Gravel Strong | Water-borne acrylic primer deep penetration with sanitizing and firming, facade | 10 | 1400 rub. |

Stages plastering

The first step of the foam block plaster walls indoors is purified using a base metal brushes. Thoroughly cleaning the surface from dust, should pay attention to the oil stains. Finding this defect, it was removed by using clay, which is first applied, and then removed from the fatty portion. If after such a procedure stain remains, it should be cut down, and close up the hole with a solution.

After cleaning, taken as a primer. First, the wall is applied to the base layer and allowed to dry. It is desirable to use to obtain a smooth surface, and after applying the solution with a spatula to level the surface, to remove the excess and add them to the remaining empty space. Over the dried first layer overlaps the second. This step is just as important, as the main task for the foam blocks primer plaster is to create conditions, maximum suitable for coupling blocks and plasters.

Regardless of the wall roughness, it is desirable not to make the layer thicker primer 2 cm. If the building envelope are too big swings, they must be eliminated by mounting plasterboard.

further procedure, how to plaster concrete blocks, It is to perform the following actions:

- Preparation plaster - rash dry mixture into a suitable container (bucket or tank) and mixing with an electric drill with a special nozzle to a consistency, reminiscent of sour cream;

- Sets grid, without which it can not do, if the walls of the house are made of molded foam blocks. The reinforcing material is stretched and secured with dowels;

- Applying a first layer of plaster;

plastering

- Drying Waiting already applied material;

- Laying topcoat, to be thinner than the first;

- Finishing room. If chosen for this painting, preference should be given special silicate paint with high vapor permeability.

detail: how best plaster foam block read here.

To preserve the water vapor permeability of foam blocks, when we Plasterer concrete blocks inside, the thickness of the inner layer should be no more do 20 mm. In this case, the thermal conductivity of the wall is uniformly increasing. A moisture, without lingering in the structure, comes out, without causing damage to the finish and appearance of mold.

Features works

An important consideration when carrying out plastering work is respect for a certain period from the beginning of construction of the building. Due to the fact that the foam immediately after manufacture has a high moisture, exceeding the permissible value during operation, plastering it is not recommended before, than six months after the erection of walls of the house.

Other finishes include nuances:

- the need for pre-sealing wide joints long before, like plaster concrete blocks indoors. This will save time, if noticeable irregularities on the walls have repeatedly primed;

- inability to use cement plaster, which does not meet the requirements of finishing materials for foam (it's desirable, mixture to have a permeability with blocks);

- the need for laying reinforcing mesh overlaps with at least 10 cm, thereby providing isolation layer. Failure to do so may lead to an increased likelihood of falling off the finishing layer after some time after the completion of.

Summing up

Ensure high quality results and a long service life can only be walling, adhering technology requirements and using suitable materials. Get it right, you get well plastered walls, able to protect the building from moisture and frost. And the house itself will stand much longer, maintaining within comfortable for its inhabitants temperature and humidity. Watch a video on plaster foam block in different ways.

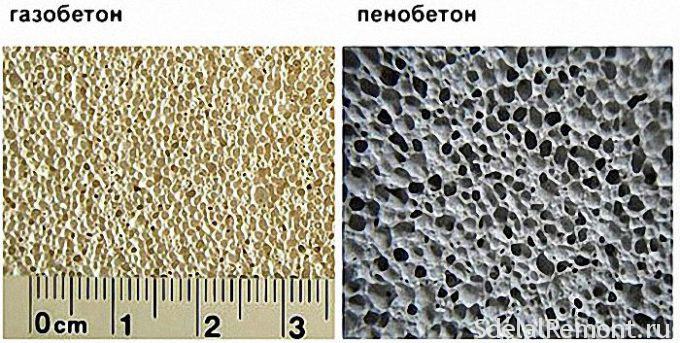

Video of the plaster and foam blocks gazoblokov