- The thermal conductivity of the mineral wool

- Mineral wool - good sound insulation

- Mineral wool - application tips

- An alternative is Ecowool. What it is?

- The main difference from other insulation Cellulose Fiber

- Flame retardant in the composition ecowool

- Installation also is its superiority over other heaters

High sound insulation and thermal insulation characteristics, as well as moisture resistance and fire resistance products made of mineral wool in the construction of objects of various values essential. Modern alternative to insulation is ecowool.

The thermal conductivity of the mineral wool

Mineral wool - heat-insulating fibrous material is, which is obtained as a result of melting of metallurgical slags, mountain silicate rocks and mixtures thereof. Of such material for producing insulating panels of construction projects, that can be used in systems of external and internal insulation. If necessary, some types of insulation installed under tension, Plasterboard or suspended ceilings. Its properties make this material an indispensable and widely used.

Because of the raw materials used for production of, rock wool, and slag is divided into stone. In the latter case, the rocks, such as the diabase, dolomite, basalt and limestone, and in the first - slag (industrial metal waste). The raw material is subjected to excessive heat to the further formation of mineral fibers by centrifugal or blow. In the melt stream is carried out by centrifugal force effect, compressed gas or steam, thereby producing the finest fibers, which subsequently pressed. The resulting mineral wool has a high soundproof and insulating ability, vlahostoyka and incombustible.

Isolation characteristics and properties, based on low thermal conductivity. Orientation compressed fibers at the same time plays an important role: scattered layout ensures better insulation, However, vertical position helps to create, while maintaining high strength plate at density. Flame resistance allows its use as a fire insulation, as the product of a material, sufficiently efficiently prevent flame spread and do not emit under its influence harmful and toxic substances.

Mineral wool - good sound insulation

Mineral wool is a fibrous insulation material based on synthetic binding,, which is obtained from mineral raw materials. The basis of mineral wool is basalt. Mineral wool is a material with low thermal conductivity coefficient. The average thickness of the mineral fiber utipletelya should be the lowest possible for a particular technology. The content of air pores and channels must reach 95 % the volume of wool.

Thermal conductivity of air is stationary mineral wool is very low, that allows to use it in many areas, and increases the efficiency of the material in the construction and other fields.

URSA Insulation is used for thermal insulation of walls, roof, houses, gender, facade. URSA insulation company you can buy here. URSA represents modern material, which represents the stone wool, formed by extruding polystyrene, which is exposed to high temperature and pressure.

Further advantages will describe URSA Insulation:

- low thermal conductivity;

- durability - it is almost not subject to wear and aging, lifetime lasts desyateletiyami;

- increased strength - plate hardly deform and withstand the load 150 kPa for 20 years old;

- zero water absorption;

- increased frost;

- environmentally friendly product;

- biological stability;

- fire resistance - the material belongs to a class G1, t. it is. difficult to combustible materials.

Sound insulation characteristics of mineral wool are also achieved due to the peculiarities of the structure of the insulation product. Between the fibers arranged randomly, not created by sound waves. water-repellent characteristics, It receives material by impregnating special structures, that if necessary, It allows insulation works objects even in rainy and wet weather.

Sound insulation characteristics of mineral wool are also achieved due to the peculiarities of the structure of the insulation product. Between the fibers arranged randomly, not created by sound waves. water-repellent characteristics, It receives material by impregnating special structures, that if necessary, It allows insulation works objects even in rainy and wet weather.

Thermal insulation mineral wool products are used in thermal insulation of multilayer systems, among which it is worth noting external insulation of "wet" type, a heater internal wall structure (sandwich panels, three-layer reinforced concrete or concrete panel, layered masonry), insulating layer is mounted in ventilated façades.

On those sites, wherein during the operation or during installation the insulation is subjected to a load, used rigid mineral wool insulation, which are also used for thermal insulation of basements of buildings and floor systems, not only insulate it, but also significantly improving soundproof properties of ceiling.

Such plates are designed for application to surfaces without isolation device screed of concrete or metal profiled decking. For the most effective thermal insulation of mineral wool should notify the contact with the surrounding air.

Mineral mats are used for thermal insulation of coolants in road communication systems, as well as for insulation of equipment and pipelines of industrial enterprises. In addition, the mineral wool mats are used for warming premises, which brought increased environmental requirements.

Mineral wool is a filler sandwich panels. It fits between the wall panels so, to the position of the fiber is vertical, which in turn gives the panels extra rigidity and ensures high thermal insulation qualities.

High water resistance and fire resistance, low thermal conductivity, as well as durability of mineral wool makes it an indispensable product when sound device- and pipe insulation, industrial buildings, residential buildings, and other objects, for these properties is so popular. At the present time mineral wool mats, plates and other products firmly occupy the first place among effective and environmentally-friendly heat insulation materials.

There are general rules, experts recommend that when dealing with such material.

Mineral wool - application tips

Strict adherence to the instructions, specified on the package to avoid unpleasant errors and rework. Cutting of such a material is performed with a special knife.

Working with a material, you need to pay attention to what, that its edges were not any torn and tattered.

From time to time the material to be installed in several layers, to obtain the desired thickness of the heat insulating layer.

Mineral wool should adhere perfectly to its surrounding structures. For qualitative effect, insulated space, It must be filled, entirely.

An alternative is Ecowool. What it is?

Ecowool - Modern insulating material, It is very popular among buyers and is gaining in popularity. Why choose it, What are its advantages and disadvantages?

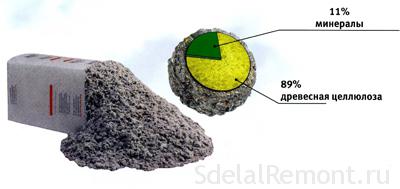

Outwardly, it's pretty loose mass of gray. It belongs to the category of cellulose insulation, designed for insulation work in the construction process. In the production, use conventional paper recycling, which serves as a basis. Cellulose Fiber manufacturing process itself is fairly simple, and the business of its manufacturing is gaining popularity. In addition to the undoubted advantages, to which consumers respond positively, ecowool has certain disadvantages. These include low density, which makes it impossible to use, eg, when laying floating floors. Nor can it be laid as a heater in complex structures by hand requires special equipment. The disadvantage of dry-stacking is a strong dustiness.

On the other hand, advantages of this material outweigh its disadvantages, and they should tell. first, what the consumer pays attention - it ecowool efficiency compared to all. Represented at the construction materials market. mold fungus, insects and rodents do not start in this material. In addition to its environmental friendliness it is resistant to fire, It has high adhesion to all major construction materials - brick, concrete, glass, metal and wood. It is necessary to remind, that it has excellent sound insulating properties, it is easy to operate. If you have the necessary equipment, this material is placed in the most inaccessible places. The air permeability of the building material is sufficiently low.

Ecowool has several unique and specific performance properties, which are able to maximize the scope primeneniyadannogo material. The industrial and civil construction, this material is widely used as a muffler and insulated filling or stuffing. Ecowool employed when forming insulating layers on a low resistance to surface temperature, in the manufacture of insulating materials for high temperatures. This building material can also be administered as an additive in asfaltobitumnye mixture and used in the construction Improvement anechoic type.

Installation is carried out either manually, or using special equipment. When manual operations stacking ecowool must first loosen its maximum helper tools, and then spread on to warm surfaces, or fill it in the cavity. When holding this material should meet the requirements for stacking density. For walls ekovaty amount should be at least 70 kilograms per cubic meter, and for the floor - about 40 kilograms per cubic meter. Cellulose Fiber Flow Calculator with different thickness formwork.

When mechanized laying Cellulose Fiber Blowing uses Fitting, who first loosen it, and then a stream of air moves the material to the place of laying. This method allows you to fill in the most remote of the cavity and the gaps, provided however laying a continuous layer without gaps. maybe, also produce a spray, that resembles the way a mechanized stacking, Once the material is applied by means of water or adhesive, which act as a binder. This stacking technology ecowool requires the use of nozzles, any special atomizer for supplying water under pressure and adhesive.

The main difference from other insulation Cellulose Fiber

Use for insulation of their own home or ecowool, namnoo contributes to more efficient heat conservation, than warming, the same volume of more traditional insulations, such, like for example rockwool, bazaltovaya ( or rock wool), fiberglass, izover and T. P. When applying ecowool a marked decrease in financial expenses for heating in winter and air conditioning in summer.

It creates a highly thermal barrier. Ecowool at warming the room filled all the voids, but also provides additional protection for all other , more combustible building materials. And when it comes to fire safety, wooden house, insulated ecowool, It is the most secure, among the majority of heaters.

Flame retardant in the composition ecowool

The composition ekovaty standard includes 100% boric acid - perfect ideal flame retardant. Bora, contained in the acid , is a natural compound, absolutely harmless to humans, used in medicine. Borates are absolutely non-volatile matter and its composition remind table salt.

The material contains no fibers, which can lead to skin allergies and lung. At warming the house with the help of ecowool no fears for the health of all the inhabitants of the house, because, the main component of Cellulose Fiber - a recycled paper. other components, used in the production, - borates are also completely harmless to humans. When you insulate their homes properly ecowool, you can absolutely not worry, for the fact that the insulation can harm your health and the health of people around you. What can be said about the stone wool, and glass wool (izover), who constantly cleaved from itself harmful and sharp fiber.

Installation also is its superiority over other heaters

Insulation ecowool when installing special pumped or blown installation manual filling method. Injected in this way the material completely fills the cavity structure, and leaves voids between the hidden cavity wiring design, plumbing and other utilities. Besides, when wet for blowing ecowool , water "dust" activates the adhesive properties of the material, absolutely not disturbing the composition and properties of insulation. Ecowool moisture is not afraid!

The use of this material is gaining momentum, due to its beneficial properties and characteristics, introduced into many stages repair of apartments with their own hands.