- One-level ceiling with his hands

- The procedure works for the manufacture of plasterboard ceilings

- Materials and tools for installation false ceiling plasterboard

- Example of mounting a single-level ceiling with his hands

- Fasten sheets of drywall to the ceiling frame independently

- Videos how to make the installation of a suspended ceiling alone

- A simple way to self assembly sheet hectoliters on the ceiling without assistants

You really wanted to make a false ceiling of plasterboard alone? People, who is engaged in repair and do it quickly on the machine. If you are a novice in such matters, and you wanted to make your own installation of suspended ceilings made of plasterboard, the installation instructions will help. Our tips Repair of apartments with their own hands help to learn this for photo and video instructions. If that is not clear, please ask in the comments, we will answer.

One-level ceiling with his hands

The ceilings of plasterboard have a number of incontestable achievements. It hides all the flaws of your ceiling (cracks, irregularities, etc.) Under such a ceiling it is very convenient to hide wires. And, the most important advantage - a smooth surface.

Plasterboard ceilings are very varied and numerous in terms of design. You will be able to make such a ceiling of GCR, for every taste. In the choice and imagination has no limits, they are of different colors, are siblings, multi-level. Plasterboard ceilings can improve the lighting in your house or apartment and give it originality and elegance. On the suspended ceilings are very convenient to arrange the light so, at your convenience, and ye like to look at it. There is an opportunity to sound insulation of the ceiling, to rid yourself of unnecessary noise.

This ceiling is suitable for any room, so to say "universal". You can do this even the ceiling in the bathroom, pre-treat the sheets need special composition, which repels water. Now consider, how the installation of the ceiling of plasterboard with their hands. To do this, below is a kind of photo-guide, we tried our best, that was the most obvious and simple. You will be available video-on assembly and installation of the ceiling independently.

The procedure works for the manufacture of plasterboard ceilings

Short designations and concepts when installing a suspended ceiling of GCR.

- Elementary (starting profile along the perimeter).

The name of the elements - Main (carrying frame profile).

- surface curve (for rigidity and reliability).

There are only two technologies Installation of walls sheets. This technology is called gypsum plasterboard Knauf and. You are free to look them up and evaluate. Skilled craftsmen prefer gypsum plasterboard technology, as our suspensions and Profile, so to speak, basis, which consists of the entire bearing false ceiling design, and which in fact are attached later, drywall sheets, to put it mildly, They are not made according to European standards, indeed much ... In short, read how good quality and make false ceilings.

The design of your ceiling from GKL, first of all, must be strong. And all other parts ( fastenings and suspensions) We must be very well fixed to the very bottom at a distance, to prevent sagging drywall sheets. because, that is sagging leads to cracking between the joints of the sheets and the appearance of hillocks. Under mounting drywall need to choose quality and technology materials.

Materials and tools for installation false ceiling plasterboard

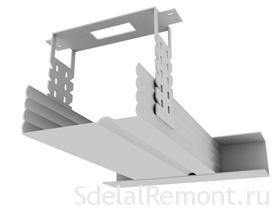

Primarily, this special hangers (photo on the left), which shall be attached to the base. That they firmly and securely fastened, use so-called plug-Nails (photo on the left) or metal-anchor wedges. More preferably - dowel-nail. To the suspension by means of so-called "kids", shown in the figure below the numeral 1, (screws with gimlet for metal, it is better to "enter" in the user's profile) attached profiles with a width 70 mm. Then there are sheets of drywall themselves wide 12,5 mm, they fasten with screws, indicated on the picture on the right under the number 2. Along the length of each piece, measure yourself, depending on the size of the ceiling. You need the same level of Laser. And do not forget about roulette, pencil, hammer and screwdriver, not do without. In the video tutorial below, all clearly shown. Calculate the required number of sheets and profiles, accessories, Take our free online calculator.

Example of mounting a single-level ceiling with his hands

First you need to identify the line to the original profile, for this use in using a laser or water level. The distance from the ceiling should be 10-20 cm do so, it would be possible to hide the wiring , communication, etc.. Put the level on the rise. The contour lines of the pencil mark on the wall. Then attach the guides to the perimeter of the room on this horizontal line step dowels 350-500 mm different from other.

The next step is marking the ceiling under the main load-bearing guide. First you need to hold parallel lines longer 125 cm, and that somewhere half plasterboard sheet. Sheets of drywall are attached with a small gap between them, and when we putty, that you could fill with a mixture of plaster to seal the joints between the sheets. Main profiles will extend around the edges of the sheet in the middle and, keep in mind. And along these lines will be secured to the metal anchor hangers-sized wedges or plugs 400 mm.

Now you can take the guide profile and insert them into the starting frame, we secured the perimeter walls of the room. The only thing, which is not desirable to do, This paste them up against the wall, you need to leave a small gap, that there is no deformation of the ceiling from various contingencies, on the similarity of thermal expansions. Consequently, insert the guides in our suspensions. The guides are attached to the suspensions of metal screws, by 2 on each side profile. On the horizontal check necessarily a long level or a laser.

Further, installation of the ceiling of plasterboard with their hands, It involves partitioning and insertion of longitudinal profiles (photo on the right). It is recommended to look at the specification of the transverse mounting drywall sheets guides about 600 mm, and a longitudinal - 400 mm. design options you can choose for yourself and look at the video. Here we look at the cross-bracing. You can easily cut the longitudinal profile of the guide scissors on metal to the desired length. Then insert the longitudinal profile between the guide also in increments of about 500mm. They must be positioned so, I would not get to meet the bonding place of guide profiles with hangers.

Longitudinal profile attached to the guide, using a special crab, photo on the left. Whatever design was stronger, use a different structure for securing the longitudinal profiles. By supporting profile attached two pieces and put them in the longitudinal. It is this method is very good structure strengthens. Secure the longitudinal profile can be via hangers, approximately in the middle of each.

It can be used to physically fix the profile to the ceiling pieces of the same profile, Only it must be pre-cut at the edges and fold the letter D. For comfort, first measure the distance from the ceiling to the lower edge of the profile, it will cut point and leave about 3 centimeters to bolt to the ceiling. Note, that fasten dowel need closer to the edge profile of the fold, to prevent sagging under the weight of sheets of drywall. With this method, you can make your own hands suspensions of any length and ceiling can be raised or lowered a little to the desired distance. Important tips on how to avoid common mistakes when working, sure to look secrets of working with a profile.

Fasten sheets of drywall to the ceiling frame independently

Here is ready for the main frame of the ceiling of GCR. Now it is necessary to sheathe sheets of plasterboard. Before this process each sheet from the ceiling special primer, it will improve the waterproofing, After fixing the treated and on the back side. Back down from the wall a few millimeters, drywall to breathe. Pin sheets transversely of the longitudinal profiles. Attach the first sheet off the wall, and the next is already starting with the first longitudinal profile. Distance (between a wall and a longitudinal profile) seal the half leaf. Thus we pass the entire ceiling. Secure the drywall sheets to all the laid profiles with screws for metal in increments of about 15-20 cm.

Cap screws do not need much utaplivat, they must be nearly flush, but that did not stick out above the plane of the drywall. This will help you stop screwdriver with stiffness, expose as, to reach the limiter responds to light the screw recess. Make a gap between the sheets 2-3 mm, that is useful for further embedding the seams with a mixture of gypsum.

That's all. It remains only to cover the joints, which are formed between the sheets. Need to putty ceiling completely, pre-primed to pass his, with putty, possibly, need to tighten the screws sticking out. It would be good to close up joints, use a special blend or mixture of plaster. It applied adhesive reinforcing mesh, fiberglass. And smooth with a spatula all, that it is not stuck. When everything is dry, leveled by divorce plastered all areas of fine sandpaper. Likewise processed and gaps, which are formed between the wall and the sheets of plasterboard. Ceiling plaster mixture fully puttied, try to do it without a divorce, if you do paintable, and if under the wallpaper, then this may not be seen.

Here is ready to ceiling plasterboard, made by hand. Then you can do with it whatever you like. Wallpapering, paint and so on. If you did everything right, the ceiling will serve you for a very long time. Ceilings are multi-level and it is written in this article. Now check out the video installation instructions, to consolidate the knowledge to practice.

Videos how to make the installation of a suspended ceiling alone

A simple way to self assembly sheet hectoliters on the ceiling without assistants

great video, sorry only single storey ceiling

Help me pick a photo about the ceilings in the apartment

tell me whether you can use instead of the usual profile of a bar, hall size 1.85 on 3.00 m, bar thickness 50 mm, plasterboard 9.5 mm

In a dry environment, possible to use a wooden frame under the plasterboard obrishotki, you need only a good effort in the frame joints ideally produce coated plasterboard in two layers. This is to ensure that there are no cracks in the joints in the future. Note that the single-layer coating tape serpyanka not eliminate the cracks.

Thank you for the article! Little is said about the size of, thickness, champion drywall…

Tell me I have a complicated roof on the loggia he did not direct horizontal, and trapezoidal, We want to close this gap with plasterboard and warm and really do it, never seen such ceilings already finished

Knauf technology allows us to produce any form of ceiling, even manufactured dome. In the presence of the masters, who have at least completed the course (Krasgorske in the Moscow region.) or see video lessons this business 1 day.

Well we take into account the wishes and put the calculator