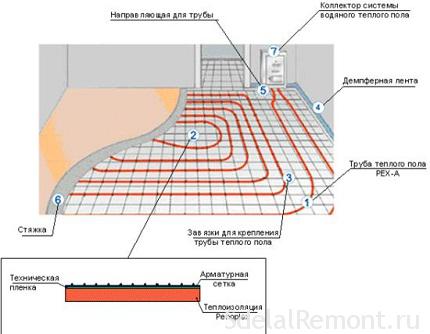

floor heating system has become an excellent solution, allows owners of new homes or apartments to abandon the traditional heating pipes. Electrical appliances may be the main source of space heating system, and part of the combined systems with radiators, if the climate is quite severe.

With replacing electrical systems over time came water, that, even more difficult to install, but it is much safer and more economical power. And it is important to be able to understand that, how to approach the selection of pipe material for water floor heating, and what to look for when choosing a.

Requirements for pipes

First we need to understand, that the pipes are used for heating, and therefore has no place in the system of ordinary pipes, used for cold or hot water. The main factor, which should have heating pipes - durability, because changes in temperature and pressure will always load the entire system.

To get the best possible installation, for floor heating pipes must have a high resistance to bending, that is, to prevent cracks or fractures. Flexibility - another important quality, which should have heating pipes, after all installation work has been carried out manually, and thus bend the pipe will have hands.

During the operation of heating system must be provided with protection against oxidation, and therefore, pipes must be well insulated and fully sealed. These factors also help to minimize the corrosive effects on the system.

If we talk about the final choice of material, then all of the above characteristics match pipe:

- metalloplastika;

- XLPE;

- polypropylene;

- copper.

All pipes, produced a water floor heating systems are performed diameter 16-20 mm, withstand temperatures of up to 120 degrees Celsius and a pressure of 5 have.

pipe manufacturers

The special place in the selection of the pipe, regardless of the selected material, play manufacturer name. A good reputation will allow you to be sure, that products are guaranteed to perform its purpose, and the probability of a defect will tend to zero.

Among the popular brands can be identified Rehau (known for pipes of crosslinked polyethylene), Valtec (pipes of metal and polypropylene), KERMI (of metal) Oventrop, Wieland, Q-Tec (pipes made of copper and polypropylene).

Pros and cons of pipe materials

For water floor heating manufactured from metallopolymers, polypropylene, copper and XLPE. Consider the basic characteristics and features of the use of each of these materials.

metalloplastik

The popularity of metal pipes due to the cheapness of the material, and the lack of need for additional hardware to connect them - for connection via compression fittings and wrench enough manpower. The tubes can withstand temperatures up to 95-110 degrees and very high rate of pressure - can be operated with up to 20 atmospheres.

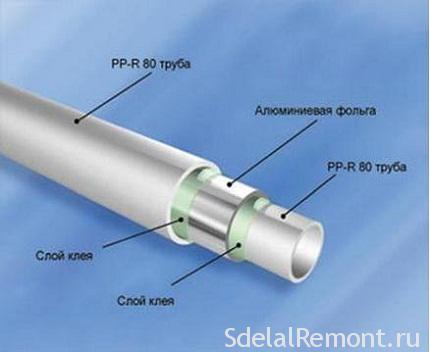

Structure of metal pipes is two polyethylene layer, between which the metal tube, made of aluminum. Between the layers of aluminum and polyethylene is the adhesive composition, which connects all the layers into a single structure.

The aluminum tube is designed to give structural strength, and also prevents the penetration of oxygen in the system. Also, it is intended to reduce the relative change in length of the tube from temperature extremes, due to the low coefficient of thermal expansion. Polymers protect aluminum from corrosion and adverse effect of coolant.

Note other advantages of metal pipes:

- low price and ease of installation of pipes;

- good flexibility - possible bending radius to 7 pipe diameters;

- lightweight construction;

- good sound insulation characteristics.

Unfortunately, pipes made of metal have a number of disadvantages. First of all, because of, that polyethylene and different coefficients of expansion of aluminum, during the operation possible pipe separation due to poor adhesive, connecting layers. It can also lead to weakening of the compounds, because of which the field can flow pipe fittings.

Secondly, Metal pipes are very unreliable in terms of mechanical strength. Any small crack can form cracks, which after a while start to leak. This should be taken into account in the system assembly, not pinch the tube at connections, to avoid cut, which necessarily will leak.

AND, third, despite, they themselves quite pipes are cheap, the total cost of the system, including fittings, may be higher, than, let us say, systems from polypropylene. Considering this, metalloplastika application may not be the most advantageous embodiment.

Pipe diameters are supplied 16, 18 and 20 mm, the length of one tube is 50, 100 and 200 m, thickness 2 mm.

polypropylene

Using polypropylene tubes (PP labeling) It can be achieved by structures of any complexity. Structurally, such pipes are unified body, Unlike metal and plastic, they do not have a metal layer. This can translate into less obvious - the polymer higher coefficient of linear expansion.

To reduce the coefficient of expansion, It applied the reinforcement pipes with aluminum or fiberglass

Advantages similar to those, which has repoussage:

- no corrosion;

- low cost tubes;

- high temperature and pressure indicators, which can withstand the system - before 110 degrees Celsius and up to 20 atmospheres;

- high flexibility - the bending radius may be 8-9 pipe diameters.

The connection is made by means of the welding machine, which results in a further advantage - the absence of leaks at the junction. Such a process can allow the entire system zamonolitit, unlike metal pipes, that it does not fit.

Feature polymeric composition gives resistance to unfreeze. It means, that even if the liquid in the cold system, it does not affect the soundness of pipes - at thawing form return to the original view. but, there is a lower temperature limit, in which the assembly can be carried out - not less 15 degrees Celsius.

Cross-linked polyethylene

Among the polymeric materials, polyethylene (ON) is the leader in distribution in the environment of heating pipes. If earlier conventional polyethylene used for the transport of cold water, due to lower strength at temperatures of 50 degrees Celsius, near the end 20 Century was able to tie the polyethylene molecules, or otherwise "sew" them.

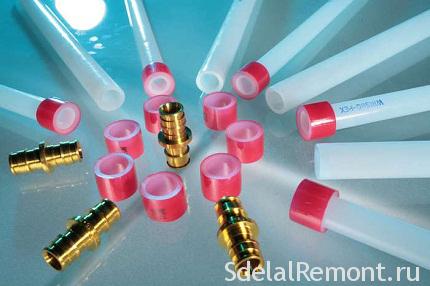

such material (cross-linked polyethylene PE-X marked) It has the best indicators of strength and resistance to high temperatures and UV radiation. but, Unlike polypropylene, weld pipes together fail of the peculiarities of the chemical composition. However, crosslinked polyethylene has sufficient flexibility for use of fittings, which will be of high integrity.

Different ways to "cross-linking" molecules, depending on the material characteristics which may vary. It is recommended to choose the tube type PE-X-b, in which the density of the "cross-linking" is 65%.

XLPE pipes can withstand the flow temperature of 0 to 95 degrees Celsius, and mounting system can be performed even at temperatures below freezing (to - 15 degrees Celsius). System pressure can reach 10-12 atmospheres. bending can be done manually before 7 diameters, however, if necessary, you can use a larger radius building Venom. Separately, it is worth noting, that the material is highly resistant to chemical and biological attack and corrosion.

Outer tubes for heating diameter may be 16 or 20 mm, thickness - 2 mm, Pipe spools supplied by 240-300 m.

Copper

As regards the application of full metal pipes for water floor heating, the copper - out of competition. The highest range of temperatures and pressures, at which the system can work, making copper pipes most versatile of all pictures.

Copper pipes are very long and are able to grow old without injury endure frequent freezing, which is particularly practical in domestic conditions - in compliance with the requirements for use copper pipes withstand 50 winters without repair or replacement. Besides, they are well-bend, manually, you can reach a bend in the 6-8 pipe diameters, which is very useful when installing the system.

Copper tubes are operated at temperatures of from -160 to 200 degrees centigrade and the pressure in the system by 10 to 27 atmospheres

Note disadvantages and copper pipes:

- fluid must have suitable acidity and stiffness, which can cause pitting corrosion of pipes;

- frequent emptying of undesirable system;

- copper can not avoid contact with other materials, so as not to manifest electromechanical corrosion.

Well, the most obvious shortcoming of copper pipes - their high cost. Average, manufacturers offer options, at 2-3 times more, than, eg, polyethylene pipes. It is also more expensive and will be the installation of the system - to work need a press machine to connect pipes by using a press-fitting. Self installing pipes as questionable, because for competent work with the equipment will need the presence of experts, which also result in costs.

The diameters of copper tube may be 16, 20, 26 and 32 mm, and length - 100 or 200 m. Pipe Thickness - 2 mm.

Which option is the most optimal?

If the monetary component does not bother you, then the best option would be warm floors made of copper tubing - high heat dissipation and durability are important advantages. but, well suited and polyethylene pipes - they are cheaper, and given, that the pipes are chosen for domestic homes and apartments, They are well suited for the characteristics required.

Concerning, floor heating system installation, almost all the variants of the capacity to conduct their own works. But, when it comes to copper and metal-plastic pipes, it may need professional help, in the future, mounted system could delight you warm without problems.