modern radiator producers do not get tired to extol the quality and efficiency of its products. In fairness, we note, that progress in this area does have, but the tests in practice shows, that by themselves these infrared film floor heating systems are unable to cope with the long winter heating. Rationalization of heating residential apartments requires the implementation of complex solutions, the only way to achieve a truly comfortable environment. One solution to the problem - the system of floor heating film, whose operation is based on the use of infra-red waves.

Pros and cons of film warm floor

The main operational benefits of these systems:

- IR wave length 5-25 microns only heats the surface, through which it passes, but not heat (Consequently, and does not dry), Unlike electrical radiators and floor heaters, the air itself. This allows you to maintain optimum microclimate parameters without the use of humidifiers;

- heating of the entire floor surface provides a uniform temperature throughout the room and the absence of hot and cold zones;

- the system characterized by low inertia and fast response time - the effect of the inclusion becomes visible after a few minutes;

- the effectiveness of even the most modern radiators and floor units reduced convection: near the ceiling is always warmer, at floor level is always cool. The system, directly embedded into the floor, this drawback is not present - as the heat source serves the flooring itself, so the temperature is always the same at all levels;

- density: installation of such a system raises the floor for no more than 3 cm (heating mats with the heating cables thicker than themselves, water systems require a concrete screed, conceals a few centimeters);

- efficiency - compared to other embedded film floor systems consumes 20% less electricity.

Uniform distribution of heat in the heating film floors

benefits enough, but, obviously, that infrared film floor would have supplanted all its competitors from the market, if it had some shortcomings. They have other moments:

- easy installation - a relative concept. Silver contacts require caution and care - with the improper installation of the need to replace contact (and their number included limited), and even cut the film;

- film floor can be installed without ties, but leveling the subfloor, yet, must (however, when it comes to laying a laminate, avoid this stage would not have succeeded);

- IR-waves were not air dried, but only if local heating is switched off, and that, in turn, It entails the need to increase the heating power, that would negate the energy savings. Will have to find a reasonable balance by experimentation;

- restrictions on the selection of furniture: solid base or legs are too low will result in overheating of the floor, furniture and the film itself, thus reducing its service life.

What type of floor selected

Film floor is ideal for the average residential area (20-40 m2). But in small rooms (eg, bathroom) using cabling or heating mats more rationally - they are easier to install. The rooms, area which exceeds 50 m2, film floor may also not be sufficiently effective in terms of cost - the film needs high power, and it will consume more electricity, than a similar water system.

The particular type of IR film depends upon the flooring system and placing.

Depending on the components used and structural performance, the film is classified into two types: carbon and bimetal.

In the first case, the heating element is used carbon fiber from carbonaceous paste, sometimes coated with a graphite, sealed between two layers of Mylar film. In the second thin plates of aluminum and copper disposed between layers of an elastic polyurethane film. The carbon film has a wide range of applications, moreover, it can be mounted on horizontal surfaces. It can be placed under the granite tile and under.

The bimetallic film shows well-behaved in combination with soft floor coverings, but under the tile can not be laid. In addition, it is somewhat difficult to install - no ground makes it necessary to include the RCD supply chain. At a cost of both options are about the same, but only if, if the carbon fiber in the first film type has no carbon coating - it increases the lifetime of the system, but it leads to higher prices.

Mounting film sex

The first stage - the preparation of the base. It should be smooth, without potholes and mounds, maximum vertical drop - 3 millimeter to two meters of floor space. If more, the film can not be laid, you first need to deepen and wipe to remove the protrusions. If stacking is carried out on the old surface without removing it - it should be smooth, strong and not cave in.

If the base to meet these requirements, before starting work, it is desirable to mark, based on the film width. It is also desirable to directly determine the location controller (in most cases it is not included with your system, so that his choice - it is the landlord) and the method of its installation. If you plan to do the wiring hidden, then cut Stroebe, drilling holes for the output cable and mounting holes for the regulator itself - all these issues have to also decide in advance.

Further, necessary to lay on the basis of the thermally reflective layer. This may be polyethylene foam or rubber with metallic coating. After that, you can start cutting and stacking of the film. important nuances: the film can be cut only by the designated manufacturer of cut lines, it is laid down is strictly copper bus. Between adjacent tapes is necessary to provide a gap (its value indicates the coating manufacturer instructions).

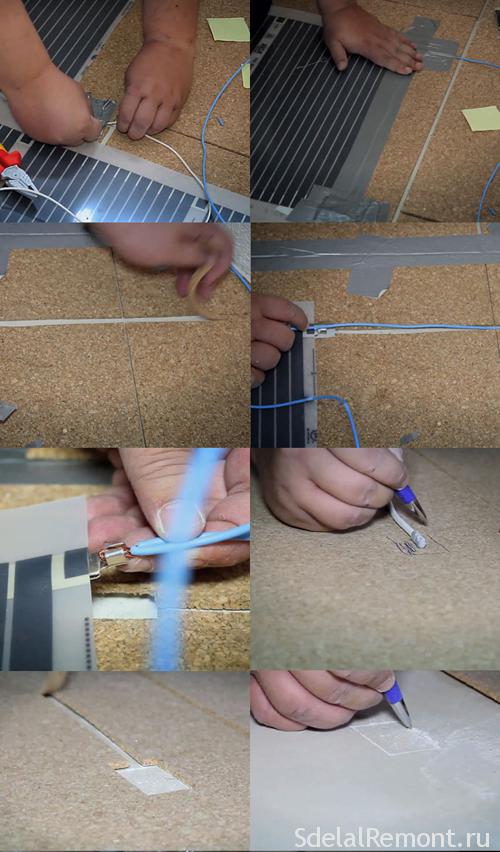

Thereafter, at one end of the fabric with a pair of pliers jaws are mounted (It is necessary to ensure good contact patch between the tire and the plane of the clamping), in which are then inserted into the conductive cables. open spaces (the exposed portion of the wire and place it with a clamp connection) insulated with bitumen insulation (supplied), also necessary to isolate the bare bus bars on the second end. Further, on the lower side of the film sensor is mounted, it is fixed by the same bitumen coating.

Installed contacts and thermistor lead to the appearance of hillocks on the film surface, therefore it is desirable to sink a reflective base (just cut it out of small plots). It is useful to cut a groove and a wire. After the final application, and surface inspection for the presence of mounds wires are reduced in the corrugation, corrugation fit in Stroebe (for external mounting - in the box). Now you can connect the wires from the fuser and sensor to the thermostat, and the entire system to the mains (RCD is not forgotten about when using bimetallic film).

making sure, that all the seats insulated, and wiring from the film and from the network to the thermostat conducted in full accordance with the instructions, can be tested. Initial operation is conducted at minimum power. Checked every single web of film. making sure, that everything is working fine, You can disable the system, to lay a protective film, and attempting to install floor covering.

Technical characteristics of the infrared heat-insulated floor

The following data are averaged, survey character. Specific figures should be specified from the seller system, but these data are sufficient, to roughly estimate the amount of future expenses, floor plan layout and determine the place of the thermostat location, understand, Does this fit the system in general to operate under specific conditions.

When choosing a thermostat, infrared heat-insulated floor, pay attention to the capacity of the thermostat is usually 2 kW. We need to add weight values of consumption and total value does not exceed the nominal regulator, if greater than or close to the 2 kW we recommend that you choose 3,5 kW.

The width of the cover. In most domestic systems it is 0,5 m. there are floors, focused on the use of office, at industrial sites, the baths, their width may be 0.6, 0.8, 1 m. Total energy approximately equally, but over a wide film is more expensive.

The length of the strip. Different manufacturers of the limit value of this parameter is different, It varies between 6 to 15 m. If the room is longer - it makes sense to think about the connection of separate halves and installation of two thermostats.

Power consumption of the infrared film floor. This parameter depends on the thermostat setting, so we can only speak of the peak value. It, depending on the film type and manufacturer, It varies between 150 to 230 W / m2. Average power consumption with the temperature at the film surface of 30 ° C (21-24° C at room) - from 25 to 45 W / h. More detailed underfloor heating calculation calculator online.

The manufacturer also indicates melting point film. It ranges from 120 to 220 degrees. From a consumer perspective on this option, it is better not to think - it is cheaper to spend once the installation is correct, continue to comply with the operating instructions (recall about low furniture), whereas the temperature at the surface of the film has reached this value.

How much is it

Cost of common carbon and bimetallic systems ranges from 500 to 1200 rubles for 1 m. Floors with carbon fiber elements and graphite are more expensive spraying, their price can go up to 1800 rubles. But such systems are more reliable, as evidenced by even a guarantee - in the first case it is a maximum of 15 years old, the second at least 20. In the same time, Much depends on the manufacturer - the Caleo, eg, there are systems and 2000+ rubles for 1 m2, and at Rexva can find quite good samples of 350 rubles for 1 m2.

Be careful - some dealers quote prices is not one meter, and immediately behind the roll. The length of the film in a roll is indicated, in this case it is necessary to recalculate the cost of a meter manually.

It is also necessary to add the cost of heat-reflecting base (from 60 to 150 rubles for 1 m2. depending on the type) and thermostat. There are already more solid Extension, talk about some average prices hard. The simplest mechanical thermostat for underfloor heating with several stages - for 1198 rubles, I met at Leroy Merlin. touchscreen programmable (Work Timer, maintaining a certain temperature, and so on) - from 2500 rubles. Good thermostat is the most expensive part of the infrared film floor heating.

When calculating be considered, whether IR-film function as the sole source of heat or in conjunction with other systems. In the former case does not need to cover less 70% gender, Second only traditionally cold areas can be covered (far away from the battery, close to the front door).

Cost of installation depends on the completeness of the package (what he needs - he defines the consumer). When ordering in the third-party organizations, the price immediately after the laying of the film and its connection to the thermostat ranges from 200 to 400 rubles per square meter. All additional work - cutting cutting grooves, installation and control connection, installation of flooring and baseboards are paid separately. That's the approximate cost of laying the warm infrared floor.