Laminate is a new high-quality coating, meet many requirements. But to properly perform its functions it will be only with proper technique under its styling, which is not only in the preparation of the base, but also the type of lining material. What kind of support to choose a laminate depends on the type of subfloor and additional functions. for example, heating.

purpose pads

The substrate on the mission carries out lots of different functions. Although, it would seem that, support - is needed in order, to put under anything and everything. Not so simple, because the base material can be any: Concrete, old wooden floor, tiles, etc.. All this accordingly requires a certain lamination, but there is one requirement, to be performed by each of them religiously - ventilation. Respectively, the best substrate for laminate - it is the, which ensures good ventilation of both the base, and topcoat. What is the ventilation, probably, it is not necessary to specify, but to remind all the same it would be appropriate. It is necessary to carry out the coating and drying of the condensate subfloor, possible dampness and rottenness. Thereby eliminating the possibility of the appearance of the fungus, mold and other hostility. It's not only damaging to himself laminate, but also very dangerous for human health, which will breathe these spores malicious entities.

support functions

Besides ventilation lining material performs several important functions:

- soundproofing. The second most important feature, which more than anything else it is important to stay calm. Laminate is a very dense material, which will be a good conductor of sound, to create on its surface. Due to the dense structure, it will be transmitted to the w / w plate, which also is a good conductor and simultaneously resonator, amplifying the sound repeatedly.

- Alignment of small irregularities. Any lining laminate has a soft and resilient fabric structure simultaneously, which makes it possible to compensate for all pits and projections, creating an ideal front surface.

If you have an unpleasant creaking or flex floor that will help you Tips to eliminate squeaks laminate.

Types of interlining

On sale there are several varieties of substrates for laminate. Each of them has its own specific purpose. TO, Sorry, without paving of impossible, because its perforated type is not for sale, and it is not planned in the production. Besides such floor will not as a decorative and protective coating, and anguish for housewives.

so, on the market today are the following types of lining materials:

- EPS;

- bung;

- cork rubber or bitumen-cork.

The most common use of expanded polystyrene is exactly under the laminate. Why? Because it is an extruded material with closed pores. In addition, he is one of the cheapest used for sex. It has the following properties:

- not susceptible to rotting and disintegrating over time;

- It has no interest for rodents and vermin;

- resistant to moisture.

Besides, polystyrene substrate under a laminate surprisingly well keeps the heat. Due to the resistance to moist environments it can be used on any base: tree, tile, bare concrete, etc.. To increase the effect of heat accumulation and paving foil layer, which reflects infrared rays (directly heat itself), concentrating them in the interior of the room.

Also, the substrate of polystyrene will not change their geometrical dimensions and thicknesses by prolonged exposure. This is due primarily to the dense structure, allowing to withstand heavy loads. What makes it possible and necessary to use it in places with high attendance and high noise levels, because the porosity of the material effectively isolate the sounds, generated when walking on the laminate even heels.

The next type - the substrate under a laminate cork. It is a material of natural origin and machining. It is an excellent thermal insulator, even more, than the first embodiment. Just stuff, having sufficiently high longitudinal strength, It will be an excellent basis for a floating floor. It does not lose its shape and does not cease to carry out its direct functions. Cork underlay for laminate process is not affected by rot and mold. As high-lining material cork has high ecological. This makes it possible to use it in rooms of any type destination: kitchen, bedroom, living room, etc..

It is a good thermal insulator, suberic substrate has characteristics quite low aeration, because of which condensation may form on the bottom surface of the laminate. A second disadvantage of this material is its high cost, making inappropriate use of coatings with cheap.

The next type of lining material is a rubber cork underlay. Due to the production technology it has improved performance of air space under the cover and over the. For its production of kraft paper used, impregnated with bitumen. In general, this material has good waterproofing properties. On the upper surface of the glued pieces of sizes of plugs 2 to 3 mm, what, as a matter of fact, and provides the necessary exchange. At its core, cork rubber is the most suitable material as a lining for laminate. But there is a lack of, which is its high cost.

Considering all the above options, choose the lining material is not so difficult. But the properties of the material should be taken into account, each manufacturing the substrate for laminate, which is better, help to understand its stability parameters and characteristics.

If properly matched substrate for laminate, floor heating is guaranteed. After all, it depends on the health of the whole family. Besides all the above types of substrates can be used in conjunction with Underfloor Heating.

The main criterion for the choice of material is the substrate thickness. From it are directly dependent on such parameters, as a thermal insulation and sound insulation.

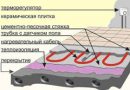

Floor technology

To ensure comfortable living and perfectly flat laying of the floor surface of the substrate must be carried out by appropriate technology. The first and main condition of laying of the material is its location across the direction of laminate boards. This allows the floor greatest strength and resistance to high loads. The second condition is the compliance with technology waterproofing. For this to be installed under the substrate layer is a polyethylene film, if one is not provided on the substrate itself. Also use foil is very effective. It not only will waterproofing, but also an excellent reflector of heat.

Laying cork substrate under the laminate is ideal without docking it overlaps with the edges by attaching double-sided tape. When this tape is glued to the subfloor. Along the edges of the walls is necessary to leave the distance, which will be the outlet for the moisture during its accumulation below the substrate. At the same time it is taken into account when using any of the types of materials.

When using extruded polystyrene foam under the laminate as a substrate, it is necessary to arrange the sheets diagonally to the direction of facial elements cover. This makes it possible to counteract the movement of the floor when under load. the foam sheets must be stacked in staggered rows, excluding the possibility of matching the coated joints. The effective thickness of the material is 3 mm, which ensures its necessary stability.

Before packing any type of substrate is necessary to align the maximum quality base. This will allow less have problems when laying laminate flooring and subsequent use.

Extruded polystyrene substrate under a laminate is by far one of the most popular and accessible thanks to its high performance to mechanical stress on the gripping and resistance to wet environment. Its thickness depends on the type of irregularities on the rough field. The more, the thicker the material to be.