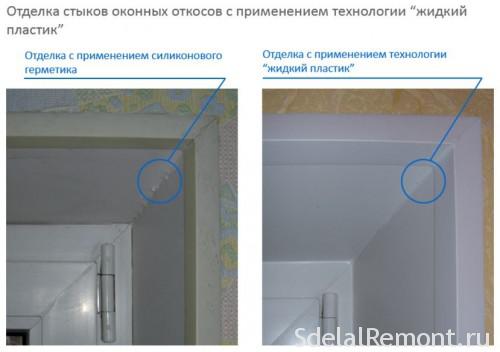

Liquid plastic for PVC windows is basically a glue sealant. Its application is necessary for finishing the joints of window frames. The advantage over the sealant, is the lack of burning and peeling from the window. Working with liquid plastic can be any polymer surfaces. He is very resistant to UV rays. Due to the perfect combination of hardened components, It creates the appearance of a solid window with a slope. Such bonding is obtained by diffusion welding, which provides details of the interchangeability of materials.

To achieve visibility whole window design and the slope allows a combination of individual solidified parts. Optimal results will be achieved by using diffuse welding technology, which will eventually replace individual sections, instead of the entire structure as a whole.

The use of the composition for the slopes

When installing plastic windows of any complexity, anyway, there is a need to install the slopes. There is a need for this because of the deformation of the old window opening as a result of the work required, aimed at the dismantling of the old windows. Also, the slope is necessary to maintain the room temperature by reducing heat loss window.

To make the slope using a special glue for PVC windows. liquid plastic. To perform all the necessary functions, slope should possess a number of specific properties and thus have a presentable appearance. Due to the similar structure of PVC plastic window and the liquid eventually form sufficiently stable, monolithic piece. The seam, made of liquid plastic, It has increased resistance to the various mechanical damage and is completely safe, Environmentally friendly material. The use of liquid plastic PVC windows also improves noise insulation layer, which will protect any building from extraneous sounds from outside, dust and dirt and impart aesthetic appearance.

Cosmofen Cosmofen plus and what is the difference

These species have a single-component liquid plastic base a reduced viscosity, and the material is very transparent. It has quickly glued effect, so it is recommended to use parts, on the surface of which there are no defects. such material, as liquid plastic Kosmofen It enjoys great popularity in the field of repair and personal services during the installation works of any complexity, in production scale, and in repairs.

Some features of the use of liquid plastic Cosmofen:

- highest resistance;

- resistance to sudden changes in temperature;

- low rate of heat loss.

Efficiency of use

liquid plastic, statement to which users do not always read, It will not be difficult to use. Before applying the adhesive, surface eliminate all kinds of dirt and dust. Then, surface thoroughly dried. From the quality of training, all depends on the result of gluing. The liquid adhesive is applied very carefully, smooth layer around the junction. on expiry 15 minutes drying glue reaches and becomes solid.

It is important to know, that the liquid plastic solidifies, reduced in volume and the seam will be more retracted.

Main characteristics of the sealant Kosmofen:

- optimum temperature ranges from +20 to +5 degrees;

- to solidify the glue will be enough 5 minutes, while for full curing will need a little more than a day;

- for optimal results the humidity of the working area should be at least 60%;

- liquid plastic properties stored for a couple of minutes after application of mass on the working surface;

- expend liquid plastic cosmofen It is taken in a ratio of 150 g / m2.

Cosmofen plus is used for installation purposes: sewerage, plumbing, outdoor advertising and aluminum structures of any complexity.

Benefits-adhesive sealantCosmofenplus:

- uskorennayapolimerizatsiya;

- resistance to sudden temperature changes;

- increased material resistance to ultraviolet rays.

Technical features and specifications:

- base resin adhesive is directly in the solvent;

- shock-viscous adhesive property in the solid state;

- the optimum working temperature of the working area will be from +5 degrees Celsius;

- durable enough for the bonding of a few minutes. The best effect can be achieved by using additional load;

- adhesive hardens completely during the day.

Tips for using Cosmofen plus-adhesive sealant

To start, bonding surfaces are cleaned from dust, moisture and different construction waste. Glue is recommended to apply uniformly over the entire surface. On assembly of parts should be done within minutes, and another will need to pour. Liquid plastic Cosmofen plus is not used for the bonding of pressure pipes. Keep sealant is recommended in a well sealed container. Time storage material at a temperature of 15 to 30 degrees one year. During the entire period of storage, a slight increase in the viscosity of the adhesive.

safety measures when working with liquid plastic

Liquid plastic is inherently dangerous element comprises cyanoacrylate, when using the sealant can not be neglected certain precautions, such as:

- people prone to allergic manifestations, not recommended to use this tool;

- glue or liquid plastic must be used exclusively in gloves with the following other mandatory precautions;

- Upon completion of work necessary to ventilate the area well;

- in order to avoid inhalation of vapors adhesive-sealant, You need to wear a mask.

How do yourself slopes

The technique of using a material such as glue for PVC windows liquid plastic, It is not classified as complex, so the mount slopes in the cellar. All necessary tools and materials are purchased at any hardware store. Of the tools needed: Scotch, stationery knife, simple pencil and a square. Necessary materials: polyurethane foam, liquid Nails, slopes and the liquid plastic.

The sequence of actions during the installation work yourself:

- mounting edge made, of the foam is cut along the window perimeter;

- made the necessary measurements of the width and length of the slope. The results are transferred to surface by means of a pencil;

- panel is cut based on the measurements, then inserted into the narrow side grooves located at the top. This will allow even notice the slightest error in the panel dimensions do not match;

- liquid nails or assembly foam applied to the portion of slope snake vnutrinney, then it is possible to insert a panel into a special groove in the wall;

- for extra strength, fiksirut taped seams;

- the same action needs to be done and with the rest of the slopes. For maximum results you need to remove all the gaps at the joints of the panels;

- After several hours all the panels are bonded to each other;

- liquid plastic is necessary to squeeze out very carefully and only in the places themselves joints. Surpluses are removed immediately with a sponge or colored fabric;

- Scotch tape is removed the next day.

The last step is gluing decorative corners with gashes under 45 degrees. Elements kleyut using sealant adhesive. Corners kleyut temporarily with duct tape around the perimeter. Masking tape can be removed easily the next day, without any difficulty. Liquid plastic can pass through joints angles , making plastic corner joint cast. Due cosmofen window slopes looks one with a window.