Making replacement of old window designs, you must either install the new sills of modern materials. Today, on top of the popularity of plastic products. The width of the panel is PVC 60 cm, which enables them to carry out the installation of virtually any wall thickness. How to install a plastic windowsill quality and reliable read on.

Content

- Preparatory work

- Installation of window sills of plastic

- Exception - the installation of wooden structures

Preparatory work

The preparatory stage includes metering and a choice of designs, tool selection, purchase of building materials. If not carried out the replacement of glass, We need to dismantle the old window sill. When replacing windows carried the complete removal of the old window structure. Installation of new glazing spend manufacturer specialists. Installation of plastic window sills can also be carried out by specialists or independently by the customer.

Installation of plastic window sill is carried out only after the installation of window frames and glazing.

When only the replacement of the panel, you must first make a correct measurement:

- Measure the width of the window opening. throws more 10 cm and the overall design length was prepared.

- The width of the panel is equal to the distance from the window to set the angle of the wall plus 5 cm on ledge. Make a wider base of the window is inappropriate, disturbed because the air circulation, causing windows to mist up.

Read more article, on the topic: the correct height and width of the window sill.

Tools and materials

To install a plastic windowsill with his own hands, You will need a set of tools:

- carpenter's level;

- electrical jigsaw or bolgarka;

- carpenter's knife and handsaw;

- ax and hammer;

- elbow;

- marker and masking tape.

Materials should be prepared:

- sealant;

- gun and mounting foam;

- sill panel;

- Three sets of substrates made of plastic or wood of different widths;

- two end caps.

Site Preparation PVC windowsill

Using a hacksaw, electric jigsaw, ax removed old design and the window frame. Along the edges of the wooden products removed cement. Purify the opening of breakaway building material, heater.

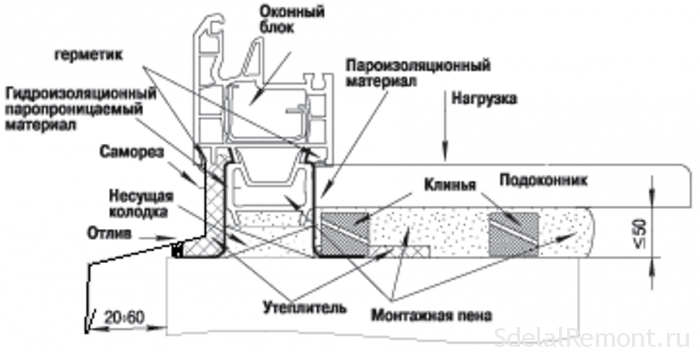

Experts establish new window PVC yet, to the window opening between the base and the lower part of the frame keeping a distance not less than 5 cm. Left opening provide support to the new design.

If you plan to install PVC window sill with his hands longer than the window opening, on each side at the base is carried Grooves. For this you need a hammer and a Bulgarian. First make the cut wall, and then hammered gently knock building material. The height of the groove is performed such, to a new panel came easily. The length of one slot for more 5 cm.

The distance between the bottom of the window opening and the frame mounting zapenivayut laying or foam insulation. After complete solidification of the foam knife cut the excess joiner. When setting the size of the plastic panel in a window aperture mark a place at a distance of not more mounting brackets 80 cm.

See article, Why plastic windows misted.

Before installing PVC products should once again clear the base of the debris and dust. Required water wetted brick, to ensure adhesion.

Installation of window sills of plastic

All materials purchased and tools ready to go. Begin with the installation of the sill.

- Determine design width. It can be the same, the width of the old base. When replacing windows and installing new PVC products expect his new width. Ideally, the edge of the panel is coplanar with the middle heating system battery. When mounting panel, edge of which stands for battery, equipped in most panel air vents. Such holes are cut in front of the battery housing. They are necessary for good ventilation in front of the window, a window structure that prevents condensation from.

- Selected length of the plastic base. When there are two windows, prefer one coherent structure. When installing window sills PVC size, equal aperture of the window, the length of the panel make shorter 10 mm.

According to choose the size of the panel makes an order to the hardware store. Master shop directly carried trim the specified parameters. Sometimes preform buy, and trimming make yourself at home.

According to choose the size of the panel makes an order to the hardware store. Master shop directly carried trim the specified parameters. Sometimes preform buy, and trimming make yourself at home.

- Support for the installation of plastic window sills made from purchased in advance of the substrates. The width of the bar should be no less 50 mm, and the length of no more than the product width. The shortest substrate should be 100 mm less than the width of the panel. Pay special attention to the thickness of the substrate. After the installation of the bar, panel should enter the space between the window sill of the window frame and the substrate.

- Before installing bars substrates grout line the surface of the base. On one design, a minimum of three substrates. The optimal distance between the bars - 40-50 cm.

- The supports are aligned strictly horizontally and check the correct installation with the level in all planes. Make control installation plastic panel. The result of the proper substrate mounting structure is dense occurrence in the gap between the window edge and the support.

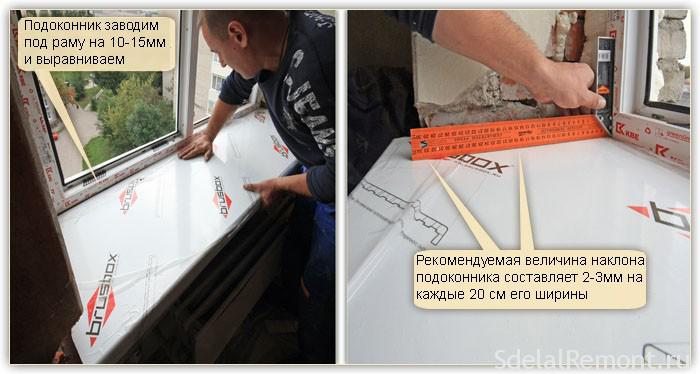

- Installation of plastic window sills with their hands begins with the removal from the, adjacent to the window, protective film. Install caps on the ends of the panel. Gently inserted on fixed support structure.

- Panel firmly takes the place. Tapping align the product with respect to the window frame. Carry out control measurement level in two directions.

- Right and left leaves a gap in the 5 mm, which makes it possible prevent the panel from the strain. At the end of the installation gaps sealed with sealant.

- Carefully zapenivayut space under the plastic window sills with foam. If the panel is poorly recorded, from an increase in the volume of foam will skew its.

- On the edges and in the center of the window opening set spacers. They are made by yourself or buy in the store transforming struts. They do not allow the mounting foam lift installed base of the window opening. When the foam hardens well, spacers dismantle and cut excess foam.

- After install soffits, proceed to plugging gaps. Along the edges are glued masking tape. Fill the gap with silicone sealant. Remove the excess and remove the masking tape.

- The protective film is removed after the completion of.

If you read the soiled foam sill, how to clean the surface of the foam.

Exception - the installation of wooden window sills

Sills made of oak wood, pine, beech, ash or cherry make the interior of the house a warm and cozy. Giving preference to natural materials, Many owners of apartments and houses an artificial plastic instead choose natural wood base. The shops sell wood panels, coated with paints of different shades of different surface textures. After making your selection, proceed to the installation of a wooden window sill with his own hands.

Preparing walls

Carry base cleaning from dust and rubbish. The surface is wetted with water, to ensure good adhesion. If there is a niche under the window, over the horizontally placed metal or wooden support, the panel is not hanging in the air. Structure of wood in this case, put a metal frame.

alignment sill

Pre expose window sill with wedges, achieving its bias into the room only 2 degrees. Along the window board is horizontally. When all the results were achieved, wedges strengthen small amount of solution, removing the workpiece.

Fixing a wooden window sill

Spread on the base layer of the solution, covering wedges on 5 mm. Mainly used grout, but it is possible to apply putty or plaster. Install a sill in place and tightly pressed against the stop into wedges. Speaking excess is removed with a spatula.

Council! For safety net is laid on top of the solution first insulating film, to protect the wood from direct contact with an aqueous solution.

Sealing and reinforcement fixing

For a more secure fit from the front through the window frame into the end of a wooden window sill to drive long screws. After completion of the support structure is embedded small gap liquid acrylic.

Now you know, how to install plastic window sill and a wooden structure on their own. Follow our advice and you will succeed. For better absorption of reading material chosen video look us about different mounting options.

All work to install better left to professionals, to strictly observe the correctness of each of the necessary steps. Be with someone and then ask.

established firms, while pleased with the results, but anything can happen.