In order to ensure reliable operation of the LEDs in 220V, you want to install the power supply for LED strip. Terms for choosing this device include the capacity calculation and determination of the type. And in the installation process is required to take into account some of the nuances.

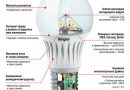

LED tape has long been included among the most popular sources of light and are used in everyday life, and industry. However, a direct connection of these devices to a conventional 220V impossible - almost immediately LEDs will fail. In order to use modern technology with a standard outlet should purchase a power supply for LED strip - a relatively inexpensive device, at which the election, but, will have to spend some time.

Most often, the problem of selecting a suitable power supply on the characteristics encountered when using tapes to 12V, common due to its affordable price. And the main ways of its solution lie in the calculation of the required power and the number of sources. AND, finally, final stages can be called to choose the appropriate model for performance and functionality of the type, and then assembling the selected device.

Calculation of power supply options

To choose the right unit 12V LED strip power can, knowing its basic characteristics and comparing them with the options available in the market model of PD. Firstly, take into account the capacity and length used for an illumination device. Performance is usually specified tape manufacturers in its specifications on the packaging (for most models of its value is equal to 4-30 V / m - more power, the brighter the LEDs light up). A length, needed to create the necessary conditions, is determined by measuring tape.

Known parameters of lighting equipment are taken into account when choosing a unit, voltage is also equal to 12V, and represents the calculated power value. The latter figure may be called the main, and the method of its determination is relatively simple. Although it requires to take into account a small margin performance (within 10-30%) to ensure proper operation and dimensions of the selected power supply.

Council: source dimensions may be relevant, if you want to mask. Too big appliance is best to replace a number of BP with lower performance, which are easier to hide - such as, for plasterboard ceiling, under the baseboard or via a special flange. Bulky unit requires the placement of specially made inside wall or furniture niche.

In order to better understand the, how to calculate the power supply for LED strip, we can consider the example of a device working kitchen area lighting:

- The total length of the perimeter is equal to 8 meters;

- To illuminate selected tape type SMD 5050 brand Epistar from 60 diodes 5x5 mm 1 meter of length. Selection is carried out according to the height of the LED placement (1 m), sozdavaemomu imi svetovomu stream (1200 lm / m) and machine the desired standard level of illumination (not less 1000 lux);

- Given the index 14,4 W / m, taken from the packaging unit, or site, selling such equipment, determined consumption - 14,4h8 = 115 W;

- Adopted a 30 percent margin, wherein power is 115h1,3 = 149.5 W;

- We find the power supply to 150 W.

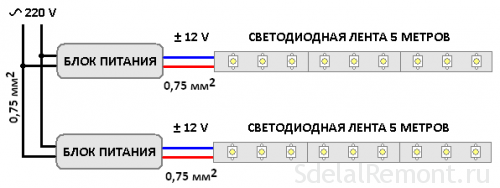

- Dimensions of all available sources to purchase large enough, therefore it is necessary to install two smaller models, calculated on 75 each W.

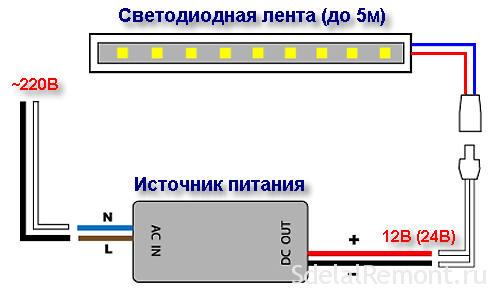

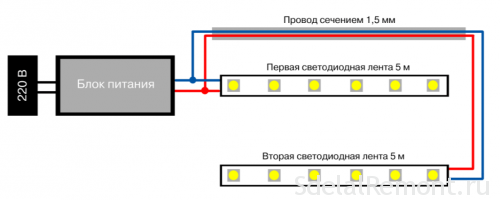

When separating belt into several parts, each connected to its source. Usually, the distance between them is in the range of 5-10 m. If a, setting power supply, It is required to cut the tape, it is done only in specially marked places. If there is no tag, cuts recommended between groups 3 LED.

Transparent table for the power supply unit 1 meter Led tapes

| type of LED | Diodov of 1 meter | Power |

| SMD 3528 | 60 | 4,8 W |

| SMD 3528 | 120 | 7,2 W |

| SMD 3528 | 240 | 16 W |

| SMD 5050 | 30 | 7,2 W |

| SMD 5050 | 60 | 14 W |

| SMD 5050 | 120 | 25 W |

Selection of a suitable embodiment

The calculation of the power supply for LED strip, and determining its capacity, selected characteristics such as a cooling device, its functionality and version. PSU cooling systems are designed to reduce the temperature of the source and prolong its life,. Such cooling may be active (with a fan in the housing), the most compact, but require periodic cleaning of dust and noisier. The second option, passive system, It takes up more space, but it is more convenient to operate and silent in operation.

By functionality can be a source of:

- ordinary, providing only the work of the tape;

- with built-in control unit (dimmer), Allows you to change the color or include only a portion of the LEDs;

- remotely controlled (by radio or infrared channel);

- stocked the maximum number of devices - and dimmer, and the remote control. This option avoids the installation of additional equipment in different places.

Embodiments of execution units

The next step is to determine, a power supply for LED strip will be on execution type - sealed, semi-hermetic or fully open. A suitable embodiment they are selected depending on, what room is illuminated by a LED strip - bathroom, kitchen, living room or production site. The maximum level of protection is needed for the illuminated areas, Located on the street.

The easiest and most popular option - open model with plastic casing. Such a power unit LED strips only partially protected from dust and is suitable for use indoors or exclusively automobiles. In the car, the source can be used to power the lighting of the ceiling or dashboard. The flat power supply unit as standard IP20 is primarily intended to illuminate the living area. Because of the relatively small power sources (to 75 W) in each room may be installed device 2-3, usually masked behind a false ceiling.

Sealed models represent blocks in housings, substantially protected from any external impact. device board is fully filled with silicone and stored in clear glass. Such sources are suitable for the creation of external vehicle lighting, for building facades, and also under conditions of high humidity and dusty. Their size and weight is much larger compared to conventional sources, but enlarged and parameters such as:

- power (to 100 W), enables longer tape feed;

- reliability and immunity to moisture, whereby the power supply units can be installed in the building, and on the street. Most often they are used for lighting signage.

It features semi-hermetic unit - the average size and relatively affordable price. They are installed in rooms with high humidity, but with a little chance to get water on the power source. for example, in the bathroom or in the kitchen, and even on the street - for lighting under the eaves. Their purpose may be powered LEDs, used in industry. For example, in the above manufacturing site is sufficient semi-hermetic embodiment. You can quickly find a reliable power supply on the website of the manufacturer of energy-efficient lighting equipment Gauss.

Basic connectivity options ice tapes to the power supply

mounting Features

Make calculations power unit for LED strip and the purchase of the source may not be the last stage of preparation for the installation of lighting. If one device is necessary for a simple one-color system, simply connect it to a lighting device. When the need to install several blocks (desirably equal power and connected with the tape portions equidistantly) should ensure their operation with a common remote controller or.

For more complex systems, using, eg, RGB multi-colored tape, It requires not only power supplies. Additional devices are controllers and amplifiers. The task of the first color management and adjustment of the illumination level, second - signal transmission from one LED to another group while maintaining brightness and color change synchronicity. it's desirable, that each unit is powered from a separate source.

Applying blocks RGB LED strip power strip themselves LEDs, can provide a periodic variation of the lighting in the room or on the street. Therefore, such systems are popular as illumination windows, cars, fountains and even columns and stairs. Establish this type of device and on suspended ceilings, and any hard to reach places, that allows you to make flexible LED tape.

Council: To simplify the design and amplifier controller can be connected to the same power supply, and that the tape itself. However, this significantly increases the size of sources.

Besides, Installation block of any type is required:

- provide a mounting process air circulation, required for cooling source. We do not recommend the installation of the device in rooms with a complete lack of ventilation;

- provide access to the unit for ease of maintenance or replacement in case of failure;

- install sources are not close to the LED strip or other units, but at some distance.

also recommended, the temperature in the room, wherein the power supply is set to LED strip, It is in the range -10 - +45 degrees. If these conditions are not met, used sealed sources with IP67 protection. For them, not use in temperatures ranging from -25 to +85 degrees.