For many screed floor like a normal solution, made of cement and sand consistency. In addition to this process of "maturation" it takes a long time, that not everyone is interested in. But now there is a similar version of the composition, but that is a completely different way is ready for use after installation work. This mixture is a semi-dry screed. It has both its advantages, and disadvantages.

notion

The composition of the mixture has a sand-cement mortar, as well as plasticizers with fiberglass. The waters here are hardly used. it is necessary, to make the mixture more tenacious, able to fully demonstrate their quality and properties. As a result, significantly reduced the terms of the finished drying solution. Will be sufficient and 3-4 days after the execution of all works.

Most often it is used in a large difference between the heights of the room, the presence of large cracks. This begin to show all the advantages of a semi-dry screeds. Floor technology this solution makes it possible to implement it on a large area premises. true, It requires the use of special equipment, which will not always be available from the usual apartment owners.

Independent implementation requires some skill, allowing to replace any instrument improvised means.

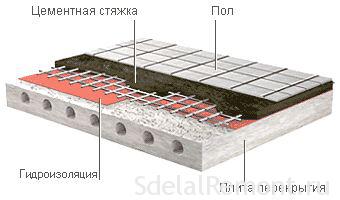

Tie layer should be on average 7-10 cm. If you make it very thin, then over time it will crack quickly. The ease of the whole mass attached fibrovolokno, which reduces the load on the overlap, however it was not. However, with this type of tie can organize warm floor, lay the tiles. The most important thing to observe all the stages and sequence of works.

It has a semi-dry floor screed pros and cons, the presence of which will depend on the proper observance of technology of installation work. Otherwise, a huge number of shortcomings in the operation and installation of completion. This will lead to an additional expenditure of money and effort.

Positive features

Benefits semi floor screed are in the following points:

- It can be carried out not only in new buildings, when slabs have virtually no damage, as well as in old buildings, including with a wooden subfloor. The last option is most common in private households.

- In carrying out the operating time appears virtually dust and dirt, that only hamper the installation of the screed.

- It has a semi-dry floor screed advantages in, that water is almost never used. It only takes a minimal amount of, to cement hydration was carried out, is part of the mixture. This minimizes the occurrence of cracks, subsidence of the whole structure. Eliminates the possibility of flooding the neighbors if all working moments.

- There is no need to acquire self-leveling mix, which, moreover, are quite expensive compared to the finished version semi-dry mixture. Self-leveling solution is usually referred to as the number of conventional.

- Upon completion of all work on the device of "rough" sex variants enough to wait 12 hours, to be able to walk on this coating. It will not be able to change their quality. the main thing, do weighty pressure. This indicates, that can be practiced without any problems finishing facilities. after 72-90 hours after closure floor screed assembly, It fits any floor covering, which is matched to the apartment.

- It is not required to finish the floor leveling, as the base becomes perfectly smooth. All standards for laying flooring fully respected.

Consequently, No additional costs will not be, and the power to spend it is not necessary to work. According to the building regulations, height differences of the finished version of ties allowed, but they should not exceed 2 mm per 2 meter base.

Consequently, No additional costs will not be, and the power to spend it is not necessary to work. According to the building regulations, height differences of the finished version of ties allowed, but they should not exceed 2 mm per 2 meter base. - The screed is easily concealed internal communications, which can only be installed in the room. It could also include a system and underfloor heating, if there is such a need. In addition, there appears semi-dry floor screed as another layer of insulation in the room.

- With special equipment for all kinds of work time is reduced, and can deliver finished solution to 25 floors. All will depend on the use of a particular type of instrument adaptations and.

- It has a floor screed advantages in, that possesses such a quality, universality. It manifests itself in the, the finished mixture can be used not only within a certain space (kitchen, bedroom, Hall), but also is used for carrying out roofing works.

- Because the waterproofing is arranged under the screed, it is precisely this layer and will minimize the possibility of flood neighbors during emergency flooding. It's kind of floor, "pillow", not permeable through the moisture.

Floor screed - Perform work not only on a surface at an angle, but also in any place, where several limited access, eg, a flight of stairs. Any complex forms and decorative elements (pillars, column) You can also lightly when using a semi-dry screed floor.

- Fiberglass reduces the specific weight of the produced variant, increases the wear resistance of the floor covering.

- The excellent properties of heat and sound insulation. This is achieved by the porosity of the finished mixture the structure.

The process of executing a semi-dry screed - As part of the mixture has only natural ingredients, supplements, which do not have any negative impact on human health, performing installation work, living in the future in this room. The raw material is a natural.

- acceptable price. The savings here is not only the materials themselves, but in the embezzlement of physical force. With minimal use of the latest, carried huge area. Performance of works due to semi-dry mixtures is high. But it requires the use of specialized equipment, which is leased or available.

- multilevel screed. Perform "roughing" floor can be with different levels of, depending on the needs of even within the same premises. Finished semi-dry screed is placed on the base of that way, how to put.

To all of them we were in the complex and has been proven in practice, you must comply with all requirements for the semi-stacking technology tie. Among the negative manifestations of violations of instruction points - Cracks, subsidence in certain places, violated the integrity of the finished base and other variants.

negative aspects

Since the screed has pros and cons, we can not forget about those items, which relate specifically to shortcomings, several deflecting the consumer from buying a ready mix. It complicates the work the winter season. This is due to the fact, that the equipment is often located on the street. Operate at significantly subzero temperatures is any very problematic.  In addition, here the sand begins to freeze together, difficulties arise with the delivery of the solution from the sand with cement through conduit. May even appear "plug" stopping the whole process.

In addition, here the sand begins to freeze together, difficulties arise with the delivery of the solution from the sand with cement through conduit. May even appear "plug" stopping the whole process.

Perform all work on the device of a semi-dry screed floor alone will be very difficult due to the fact, that it requires the use of additional equipment not only for cooking solution, but the subsequent tamping and leveling grounds. This basically comes directly from the mixture composition, as well as small amounts of water used for the solution.

For semi-dry screeds and cons are in the following paragraphs:

- "Fear" of water. If the surface of the finished base of a large amount of moisture is adjudged, then it begins to swell and crack. This is due to the cement hydration process. So it should be careful, to the quality of semi-dry screed remains at the proper level.

- The appearance of noise while walking on the floor covering, as well as the destruction beneath him.

- The low level of self-sealing, resulting in falling asleep thick tie layer. Basically, the minimum charge 40-50 mm.

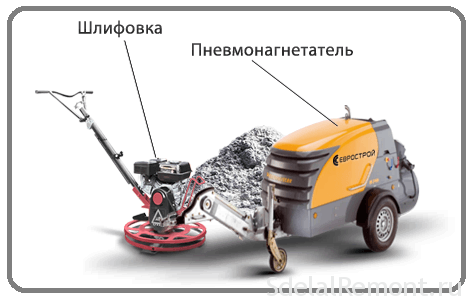

- All work is best done in a single step. Consequently, large areas at their own performing work on the device floor screed, They are not feasible. It will require not only more physical strength and an appropriate tool for the job (sander, zaglazhivayushtaya machine, Pneumosupercharger et al.). Hence, an appropriate name - mechanized dry screed.

All semi-dry floor screed cons associated with its device technology. They can and must be fought, so that the final result was as useful. Each minus ready mix and semi-dry screeds solution is eliminated very quickly. The main thing to try and make a minimum of effort.

Elimination of defects

We can not ignore the side to the semi-dry screeds pros and cons. But each of them appears only subject to installation technology, or neglect it. Hence, there are conditions in order to reduce to the minimum all the negative points.

To the fresh solution could easily "dry", it is covered with a film of polyethylene.  This protects the substrate from excessive ingress of moisture. It is best to forget about the economy, and to do everything on the conscience. If the tie layer will be insignificant, which requires technology, then during operation, it will start to crack, flooring begins to squeak thereon.

This protects the substrate from excessive ingress of moisture. It is best to forget about the economy, and to do everything on the conscience. If the tie layer will be insignificant, which requires technology, then during operation, it will start to crack, flooring begins to squeak thereon.

The proportions must comply with the manufacturer's recommendations. The only way to get a really high-quality solution, which can be used for leveling the surface of the floor of the future.

In the winter, and all kinds of work can not be stopped, and come up with various options to continue. Even on the street without any problems, you can make a room warm or heated to a certain temperature. Nobody can abolish various additives, such as, frost, and themselves hoses additionally insulated. This will allow for the installation of the base to the floor at the window to -25 degrees.

As for special equipment, it is not necessary to spend a fortune, If you are semi-dry screed in a selected room. There will be enough and mixers for construction. You can of course take all the rent, but it also requires a certain cost in the financial plan.

Resorting to device technology semi floor screed, you can reduce turnaround time, but at the same time spend a smaller amount of manpower and resources. In addition, there may already be fitted with "warm floor, and the layer moist solution will be an additional layer of insulation in the room.