Laying of floor screed can not do without the most dry mix, on the basis of which subsequently preparing the solution itself. But in addition to that provided and various additives, capable of imparting additional quality semi-dry screeds, under certain circumstances,. In addition, for a specific type of underfloor heating are provided and specific plasticisers, without which it is impossible to do. To get started is to decide on the, What are the positive features of the "application" for semi-dry mixture.

possible supplements

cement quality standard does not always have the necessary level of. Averages are M150 - M180. But sometimes you should use stronger compositions.  Besides, no harm will be to protect the coating without the use of the material for the floor. This often happens in the case of screed in basements, in the garage, the basements.

Besides, no harm will be to protect the coating without the use of the material for the floor. This often happens in the case of screed in basements, in the garage, the basements.

- antifreeze additive. Now winter is not terrible. You can safely perform the work, the main thing, to all the other components can deal with below zero temperatures. If the semi floor screed to apply this additive, the solution temperature to not afraid -15 degrees. In addition, increased strength-grade, plastic, increased level of confrontation humidity and other qualities.

- impregnation. It can be applied with a roller or spray. But not immediately after installation work, and after at least a week. The upper layer becomes stronger, and the surface itself easily repels moisture. Under certain circumstances waterproofing layer, which could be arranged in addition, not needed. It is true in the future will be difficult to apply the tile adhesive, all kinds of paints and putties. Under a parquet or laminate will be excellent for this impregnation.

- There impregnation for concrete floors, which have the same quality, but it does not reduce the adhesion of paint or adhesive.

- Paint based on polyurethane. To the floor surface is perfectly smooth and firm, such components are used after drying the prepared solution. If the mixture has fibrovolokno, plasticizer for floor screed, the paint can be applied on the semi-dry screed.

But this is only the minimum number of those, which are represented on the market. Each of the additive has a specific function, which improves the quality characteristics of the finished solution.

Advantages specialized blends

All advantages of using mixtures of additives are nested in the title, because in it reflects the quality of. So, e.g. reinforced mixture no longer requires a device of a semi-dry screed additional reinforcing elements. It can be safely diluted in the desired consistency and enjoy.

A high-strength mixture has a strength of at least branded M-250. As a result of its application get really high-quality coverage for a "rough" sex. Polusuhaya screed their own hands It comes out very strong. If necessary the solution, capable of withstanding high humidity, then the mixture was water-resistant is chosen. In this case, the final solution is ready to get tighter.

Laying semi-ties almost always accompanied by at least minor, but subsidence of the finished base. If in this case to apply the mixture, shrinkage compensated, then we obtain excellent positive development solution.

Everybody knows, which is very problematic solution to flatten a semi-dry screed on the soffit, grounds. To facilitate this process, should buy plastic mixture. It includes all the components are already available, allowing the solution to flow on their own floor space.

Plasticizers are also necessary to obtain uniformity of final solution. All operating characteristics in such a way make it possible to use them for underfloor heating. Ties density becomes higher, but, Consequently, its thickness is reduced by about 10-15%. This is important in case of the need to keep the distance from floor to ceiling. All the heating elements due to the high density of the solution are well protected from all sides. The final alignment is not necessary to produce, as the finished mixture to a semi-dry screed becomes perfectly flat on a plane.

The use of such dry mixtures for semi-dry screed allows operation even in the winter season, on the street, sites. I.e, except for in-house work, they are distributed on the outer. It is important to observe the technology, for which you are semi-dry screed manually.

The use of fiberglass

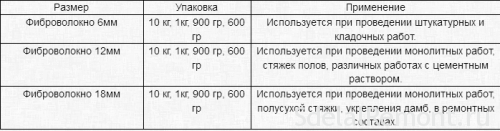

Currently, there is no need to purchase expensive steel mesh and make her laying in a semi-dry screed poured. This causes additional costs of labor power, as well as the time. Now is a great option - fibrovolokno, which gives plasticity screed, standoff bumps, bends, cracking.

The solution with filler is more resistant to external mechanical influences, absorbs less water, increase such qualities, as fire and frost. The service life of the product is increased, and quality remain at the same level. Virtually eliminates the probability of occurrence of cracks in the finished fabric in each of the stages of solidification. Any possible even minor cracks, thanks to fiberglass, interconnected, creating a single entity. Laying semi-dry floor screed is done much easier due to the plasticity of the material.

Any additive screed for underfloor heating, including fibrovolokno, do not have any negative impact on human health. There are no harmful impurities.

The use of plasticizers

should stop more detail on adding plasticizers for semi-ties into the dry mixture. The main thing to watch for the right to their addition, that will depend on the particular type. In any case, from the manufacturer will be put recommendations on the correct proportions, to be followed. Regardless of the state (liquid or dry) plasticizer for screed floor heating is to be prepared.  After it is added to a solution of, should allow time for infusion. It takes approximately 30 minutes. Re-mixing the prepared solution will allow the larger particles to grind. after another 30 min infusion, you can start working on filling a semi-dry screeds.

After it is added to a solution of, should allow time for infusion. It takes approximately 30 minutes. Re-mixing the prepared solution will allow the larger particles to grind. after another 30 min infusion, you can start working on filling a semi-dry screeds.

If we are talking about liquid version, then it will be enough and a half liters per ton of cement. Prior to addition to the solution, it should be thoroughly mixed, that each particle is uniformly distributed over the mixture.

types of plasticizers

Semi-dry floor screed with their hands steps must be carried out not only on technology, but by adding a mixture of various components. Plasticizer for semi-dry floor screed can be created not only by foreign, but domestic manufacturers. Them there is a large variety of, but emit the most optimal options:

- Premium products, having the designation "P". toxicity, Flammability no no. In this improves thermal conductivity, reliability and durability of the final version of "rough" sex.

- Superplastifikatorы. Most often used in the floor heating device in the room. It is for them and the model of the plasticizer was created. The most popular is the Ukrainian producer Sanpol. Cement seizes more slowly due to the smaller 20% Mixing water use.

- There plasticizer for underfloor based liquid rubber. Environmentally friendly here at the height of. When using it, the compensation characteristics underfloor absorbed, and the room itself receives a maximum amount of heat from the source. adhesion increases, that allows you to use a variety of means for securing the floor covering. The cost of course is very high, but it protects against the appearance of corrosion on the structural elements.

- thermoplastic. It is based on the complex salts, each of which is responsible for a certain quality. Among the positive features can be enabled: low cement setting, small entrainment of air, a high level of water resistance, frost.

Each manufacturer tries to show the market that something special, to attract customers to their side. Thereby increasing additives and technical characteristics for mixtures.